Floating medical agent prepared from food and beverage waste oil and grease and application thereof

A technology for flotation reagents and waste oil, applied in flotation, solid separation and other directions, can solve the problems of ore flotation, high temperature requirements, poor solubility and other problems that have not been involved in the field of ore flotation. good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

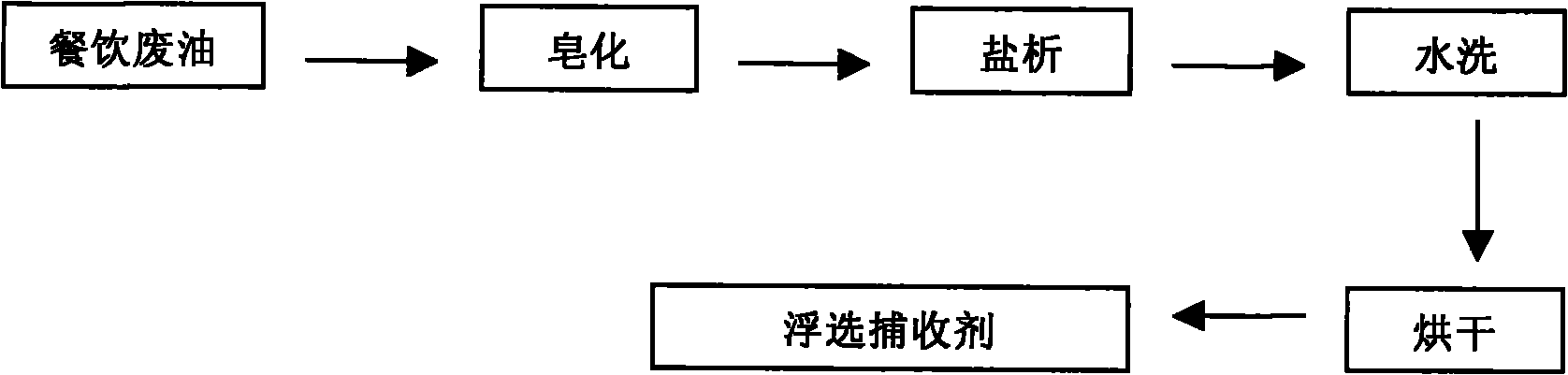

[0027] A flotation agent prepared from waste oil. For its process, see figure 1 , including refining of waste catering oil, hydrolysis and saponification of waste oil under alkaline conditions, salting out of saponification products, washing of crude soap base, and drying.

[0028] The specific implementation method is as follows:

[0029] The first step is saponification reaction: Weigh 50g of waste oil, put it into the reactor, heat and melt it in a water bath, start the stirrer to stir, and slowly add 30% sodium hydroxide prepared with 25g of sodium hydroxide dropwise at a constant temperature of 93°C. Sodium hydroxide solution is about 60mL (the mass ratio of sodium hydroxide to waste oil is 1:2), and the hydrolysis and saponification reaction is carried out for 3.5 hours. The amount of alkali added should be small at the beginning and end, and the amount added in the middle should be large. At the beginning, 1 / 4 of the total alkali amount should be put in, the reaction...

Embodiment 2

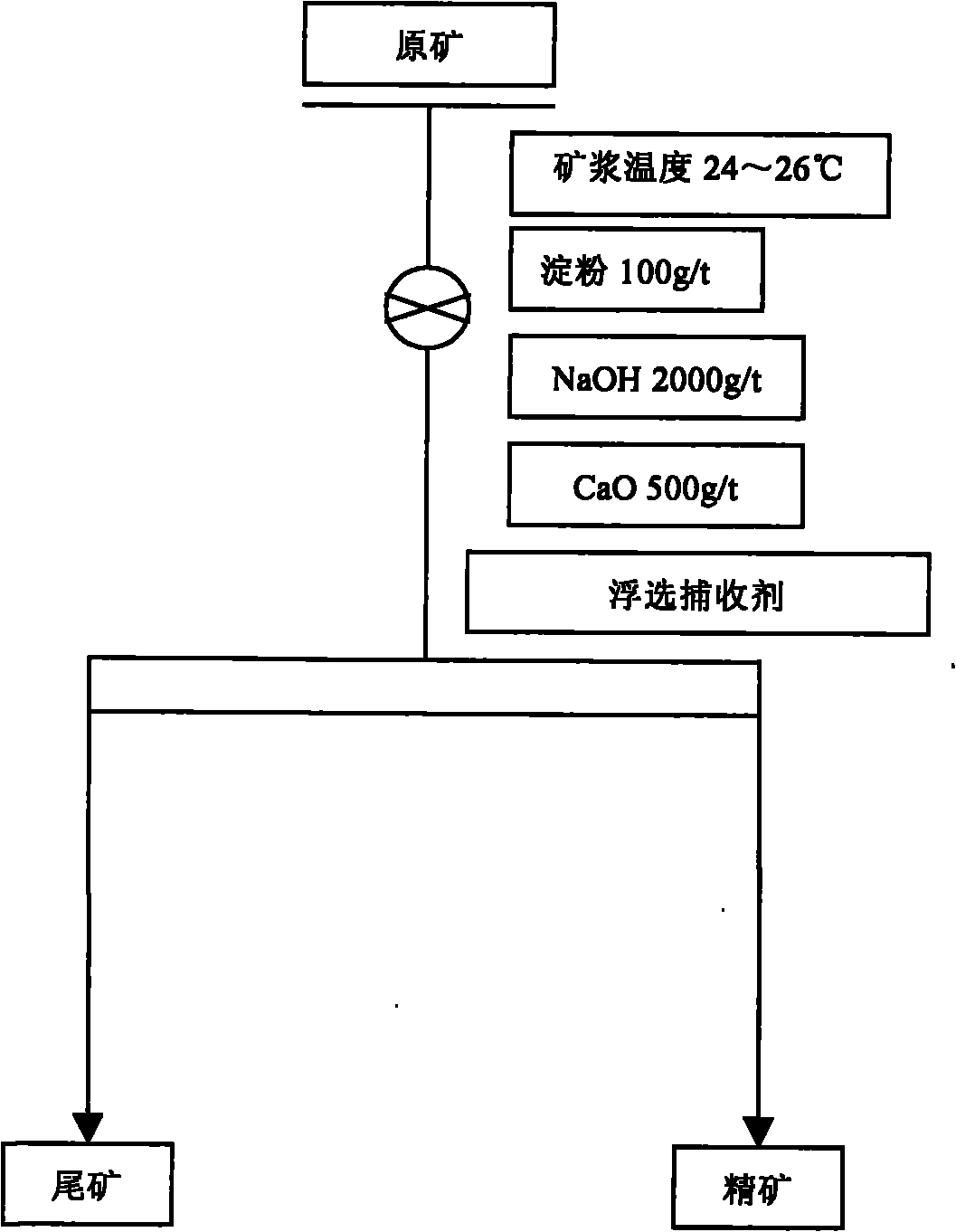

[0039] The obtained higher fatty acid sodium is used as an anion collector for reverse flotation of iron ore. The phase analysis of ore samples from Hunan San’an Mining Company found that the elements with recycling value in the ore are mainly iron, with an iron grade of 50.97%. The iron minerals are mainly hematite, accounting for 38.93%. 10.93% and a small amount of iron silicate, iron carbonate and iron sulfide. See Table 1. The particle size of the raw ore is -400um, accounting for 90%. Weigh 200g of the raw ore to obtain a pulp concentration of 25-30%. Reverse flotation is carried out at a temperature of 25-30°C. The flotation process is shown in figure 2. Add NaOH 2000g / t, starch 1000g / t, CaO 1000g / t and use the prepared high-grade fatty acid sodium as the anion collector. The dosage is 1000g / t, and iron ore reverse flotation is carried out to obtain iron concentrate with a grade of 59.23%. The flotation index is 85.3%, see Table 2.

Embodiment 3

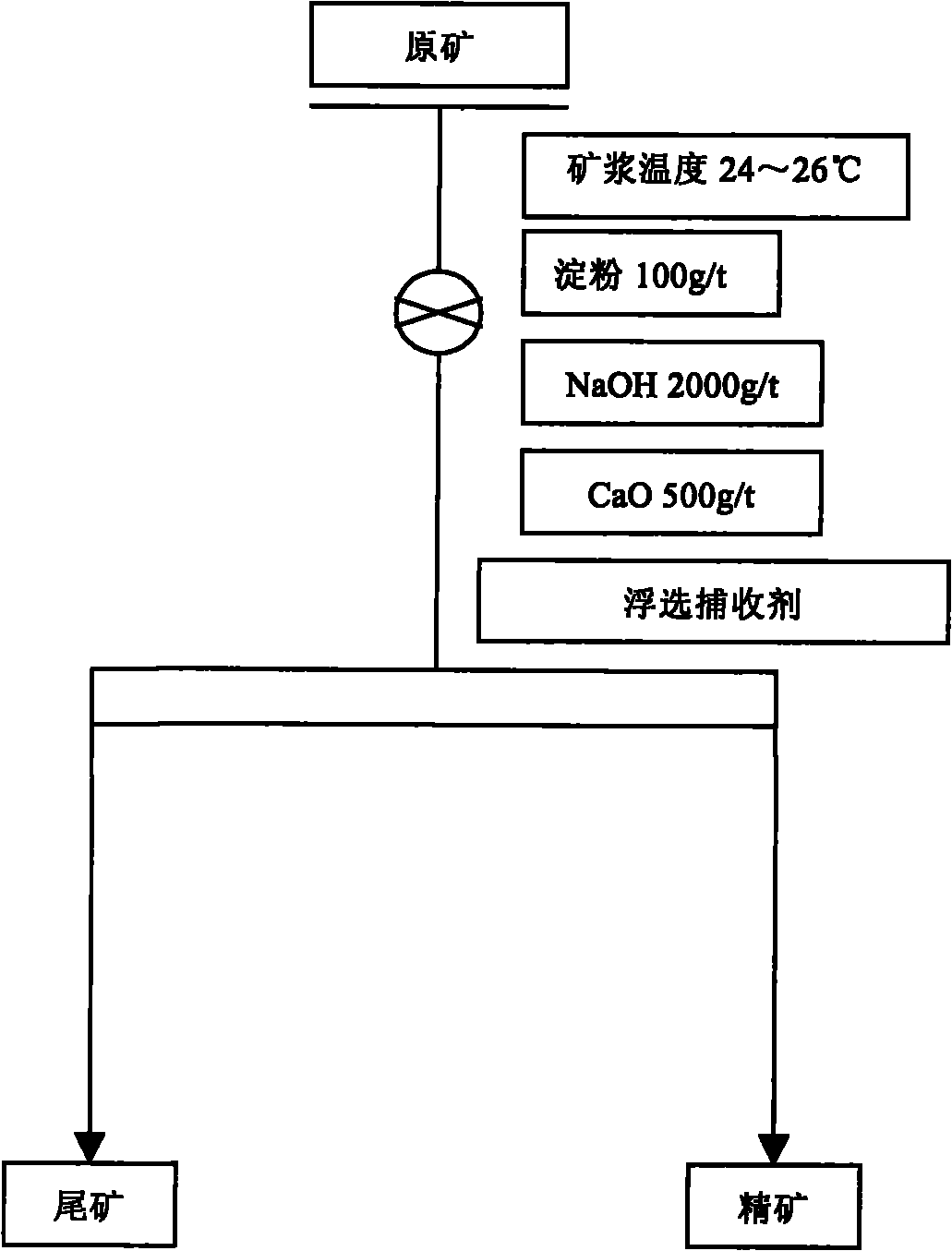

[0041] The obtained higher fatty acid sodium is used as an anion collector for reverse flotation of iron ore. The phase analysis of ore samples from Hunan San’an Mining Company found that the elements with recycling value in the ore are mainly iron, with an iron grade of 50.97%. The iron minerals are mainly hematite, accounting for 38.93%. 10.93% and a small amount of iron silicate, iron carbonate and iron sulfide. See Table 1. The particle size of the raw ore is -400um, accounting for 90%. Weigh 200g of the raw ore to obtain a pulp concentration of 25-30%. Reverse flotation is carried out at a temperature of 25-30°C. The flotation process is shown in figure 2 . Add NaOH 670g / t, starch 1000g / t, CaO 1000g / t and use the prepared high-grade fatty acid sodium as an anion collector. The dosage is 1500g / t, and iron ore reverse flotation is carried out to obtain iron ore concentrate with a grade of 64.23%. The recovery rate is The flotation index is 68.9%, see Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com