Flotation collector for silicate minerals

A technology of silicate minerals and collectors, applied in flotation, solid separation, etc., can solve the problems of high content, poor selectivity, difficult defoaming, etc., and achieve strong collecting ability, strong selectivity, and easy defoaming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] First prepare the diamine compound of the present invention,

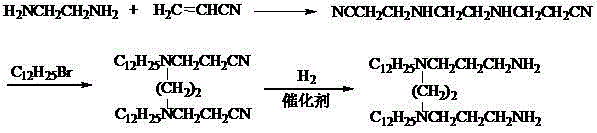

[0015] (1) When R 1 and R 2 for dodecyl, R 3 When being ethyl, the synthetic reaction of described diamine compound is as follows:

[0016]

[0017] (2) When R 1 and R 2 is octadecyl; R 3 For butyl, the synthetic reaction of described diamine compounds is as follows:

[0018]

[0019] (3) When R 1 and R 2 is an acyl group of eight carbons; R 3 For propyl group, the synthetic reaction of described diamine compounds is as follows:

[0020] (4) When R 1 and R 2 is an unsaturated acyl group of eighteen carbons; R 3 For propyl group, the synthetic reaction of described diamine compounds is as follows:

[0021]

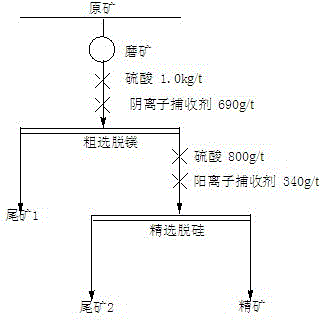

[0022] Then, the component is P 2 o 5 24.65%, MgO 3.52%, SiO 2 21.77% of the collophosite raw ore is ground to -0,074mm, accounting for 75%, the concentration of the flotation pulp is 30%, stirred for 1 minute, and after double reverse flotation, the first stage is reverse ...

Embodiment 2

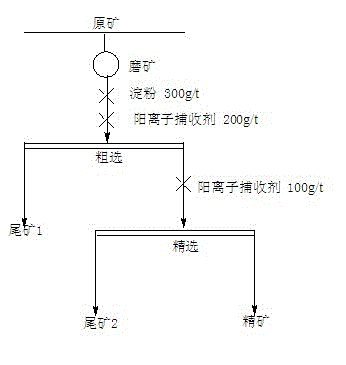

[0024] Embodiment 2: certain bauxite ore sample, raw ore Al 2 o 3 65.98%, SiO 2 12.55%, the aluminum-silicon ratio is 5.26, the ore is ground to -0,074mm, accounting for 80%, the concentration of the flotation pulp is 30%, and the pH of the slurry is 10 with sodium carbonate; one roughing and one beneficiation process is adopted, and the added chemicals and For dosage, see figure 2 . Finally, Al can be obtained 2 o 3 72.12%, SiO 2 6.51%, the aluminum-silicon ratio of the concentrate reaches 11.08, Al 2 o 3 The recovery rate is 84.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com