Formula and preparation method of phosphorite reverse flotation deoxidization magnesium collecting agent

A demagnesia removal and reverse flotation technology, applied in flotation, solid separation and other directions, can solve the problems of low separation efficiency of phosphate rock, high chemical consumption, poor foam fluidity, etc., to increase the annual processing capacity and improve the selectivity. , The effect of low content of impurities in concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The first step: prepare the mixed material. Weigh 60% of the materials oleic acid, 30% of stearic acid, and 10% of C5-C9 fatty acids in proportion, respectively add them to the reaction kettle 1, heat and stir to 100° C., and keep at constant temperature for 1 hour to make a mixed material;

[0019] The second step: heating saponification. Weigh a certain amount of the above mixed material and add it to the reaction kettle 2, then add 56.5% water and 6% solid sodium hydroxide in proportion, heat and stir to 95°C, and react at constant temperature for 1 hour;

[0020] The third step: the compounding of mixed fatty acid and surfactant. Add 5% terpineol, 5% polyoxyethylene laurate sulfonate, 1.5% TX emulsifier and 2% sodium carbonate to the reaction kettle 2, stir for 40 minutes at a constant temperature of 95°C, and pack it out of the pot That's it.

[0021] The agent has been successfully used in mineral processing production, such as in the flotation production of ph...

Embodiment 2

[0026] The first step: prepare the mixed material. Weigh 50% of the materials oleic acid, 40% of stearic acid, and 10% of C5-C9 fatty acids in proportion, respectively add them to the reaction kettle 1, heat and stir to 100° C., keep at constant temperature for 1 hour, and make a mixed material;

[0027] The second and third steps are the same as Example 1.

[0028] The agent is successfully used in mineral processing production, such as Xingfa phosphate rock flotation production.

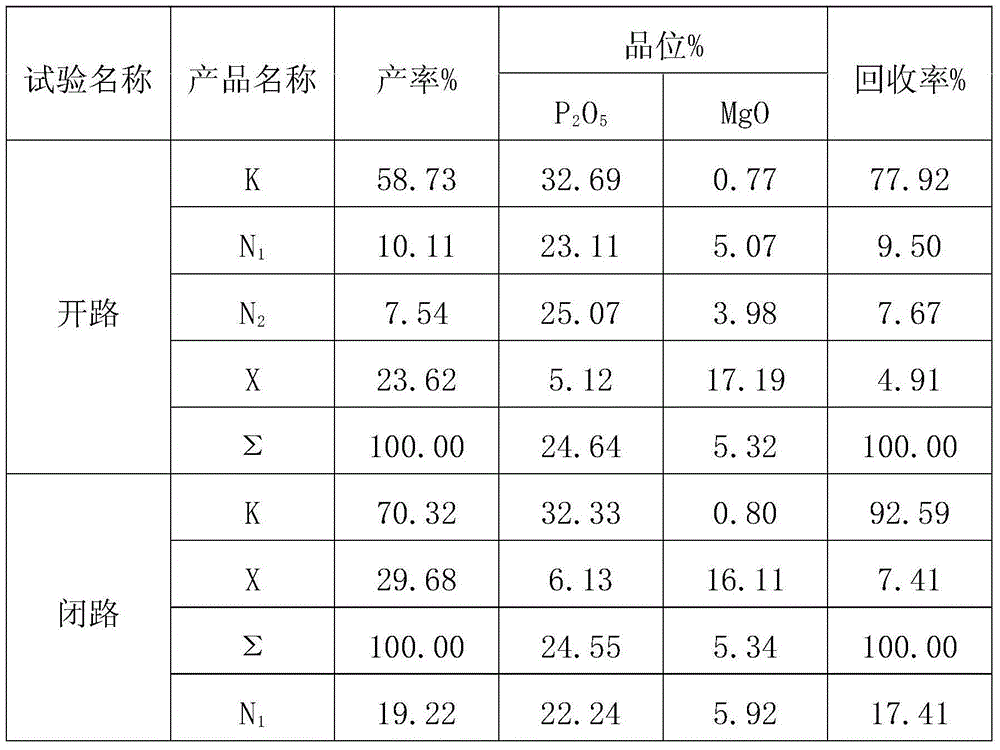

[0029] Mineral dressing test results

[0030]

Embodiment 3

[0032] The first and second steps are the same as Example 1.

[0033] The third step: the compounding of mixed fatty acid and surfactant. Add 3% terpineol, 3% polyoxyethylene laurate sulfonate, 1.5% TX emulsifier and 2% sodium carbonate to the reaction kettle 2, stir for 40 minutes at a constant temperature of 95°C, and pack it out of the pot That's it.

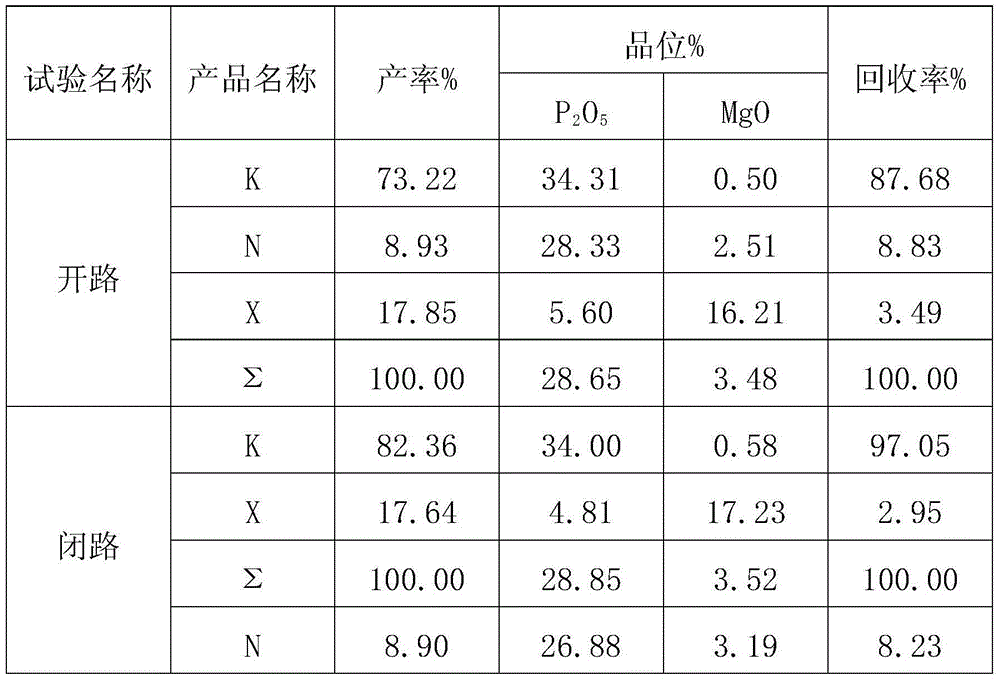

[0034] Mineral dressing test results

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com