Method for removing magnetic particles from fischer-tropsch synthetic crude oil and method for manufacturing fischer-tropsch synthetic crude oil

A technology of magnetic particles and a manufacturing method, which is applied in the preparation of liquid hydrocarbon mixture, refining by filtration, refining by electric/magnetic, etc., can solve the problems of high washing frequency of fillers, shortened washing interval, and reduced capture efficiency, etc. To extend the washing interval, improve efficiency, enhance the effect of magnetic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

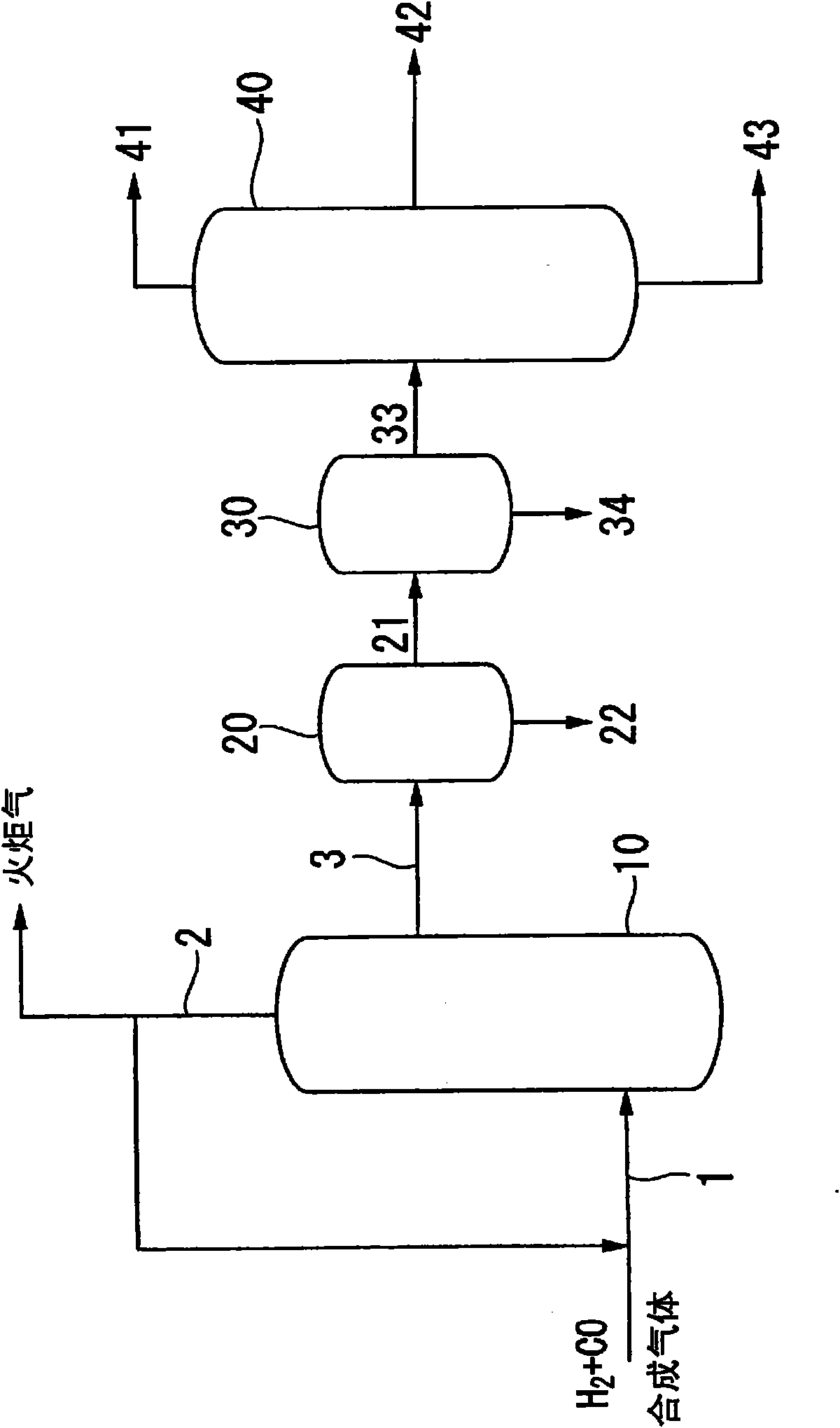

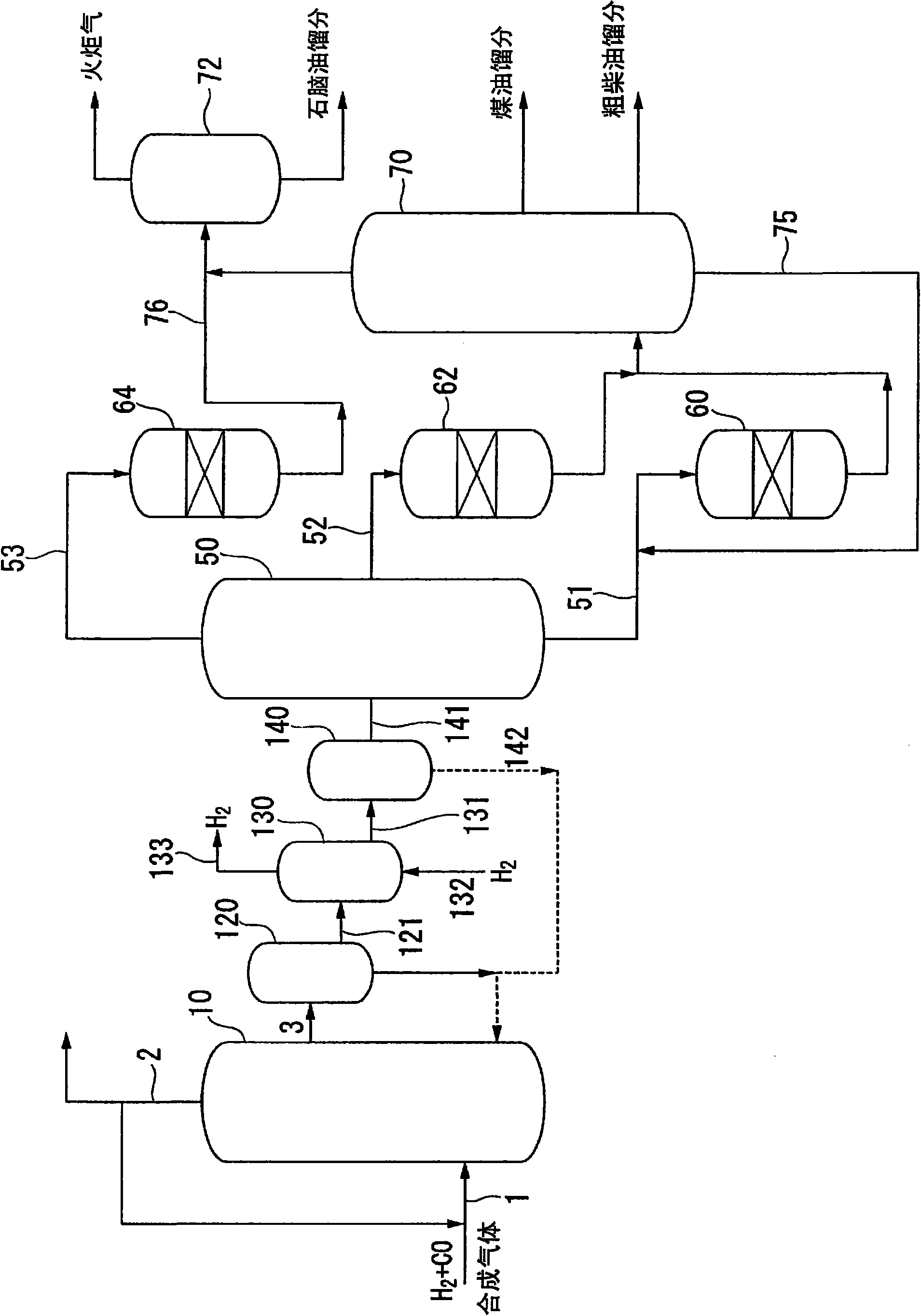

[0030] refer to figure 1 and figure 2 A first embodiment of the present invention will be described.

[0031] like figure 1 As shown, synthesis gas containing carbon monoxide gas and hydrogen gas is supplied to the FT synthesis reactor 10 through a line 1 serving as a synthesis gas supply line, and liquid hydrocarbons are produced by the FT synthesis reaction in the FT synthesis reactor 10 . Synthesis gas can be obtained, for example, by suitable reforming of hydrocarbons or the like. Methane, natural gas, LNG (liquefied natural gas), etc. are mentioned as a representative hydrocarbon. As the reforming method, partial oxidation reforming (POX) using oxygen, autothermal reforming (ATR) which is a combination of partial oxidation reforming and steam reforming, carbon dioxide gas reforming, etc. can also be used. .

[0032] Refer below figure 1 The FT synthesis process will be described.

[0033] The FT synthesis reaction system has an FT synthesis reactor 10 . The react...

Embodiment 1

[0064] Synthesis gas containing carbon monoxide and hydrogen as main components obtained by reforming natural gas is introduced into a bubble column type hydrocarbon synthesis reactor (FT synthesis reactor) 10 through a line 1, and FT catalyst particles (average particle diameter: 100 μm, Liquid hydrocarbons were synthesized by reacting in a slurry in which 30% by weight of active metal (cobalt) was suspended.

[0065] The liquid hydrocarbons synthesized in the FT synthesis reactor 10 are taken out from the reactor 10 through the line 3 as a slurry containing FT catalyst particles. The withdrawn slurry was passed through the first solid-liquid separator (gravity sedimentation separator / natural sedimentation method) 20 disposed at the rear stage of the FT synthesis reactor 10 to remove catalyst particles.

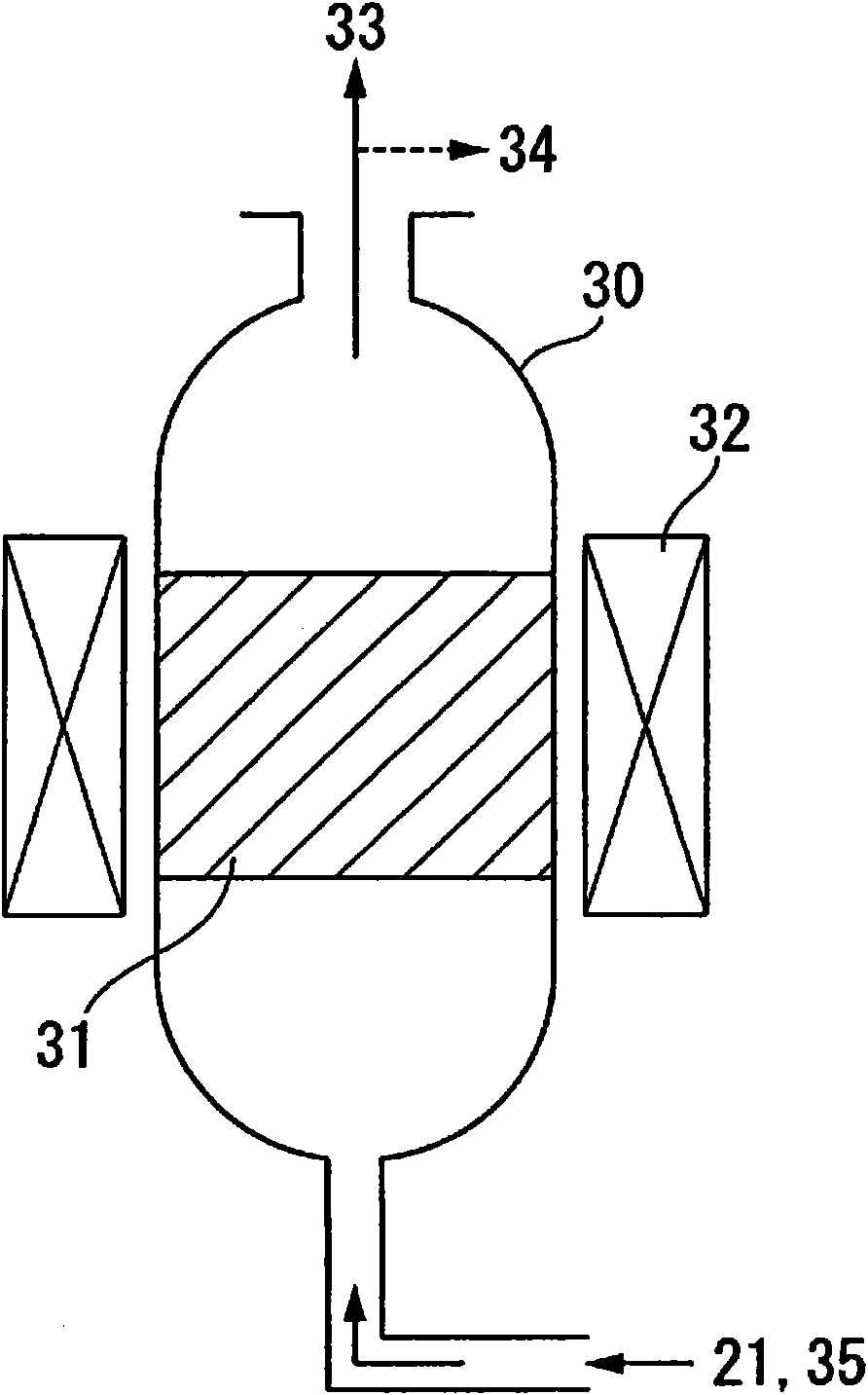

[0066] Next, the synthetic crude oil (liquid A) containing catalyst particles not separated by the first solid-liquid separator 20 is guided to an electromagnet-type high-gr...

Embodiment 2

[0072] The settling time of the gravity settling separator 20 in the first solid-liquid separation step was adjusted so that the residual particle concentration (ppm by mass) at the inlet of the magnetic separator became the concentration described in Table 1. In addition, as shown in Table 1, the treatment conditions of the high-gradient magnetic separator in the second solid-liquid separation step were changed. Except for this, the same processing as in Example 1 was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com