Tubular turbid wastewater suspended matter treatment device based on YC magnetic separation process

A wastewater suspension and magnetic separation technology, applied in the fields of magnetic/electric field water/sewage treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as inconvenient use, inability to remove adsorbed substances, and cumbersome installation. Achieve the effect of convenient installation and improve the efficiency of magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

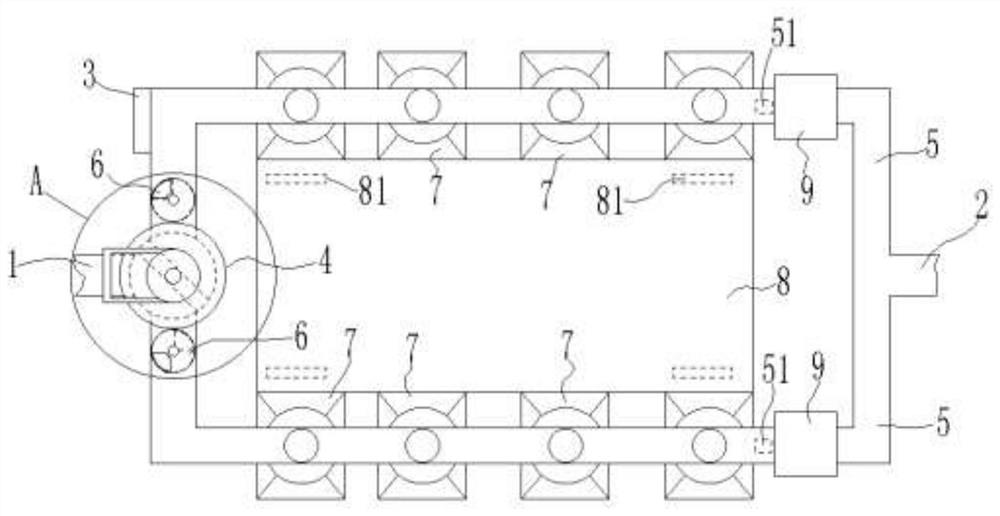

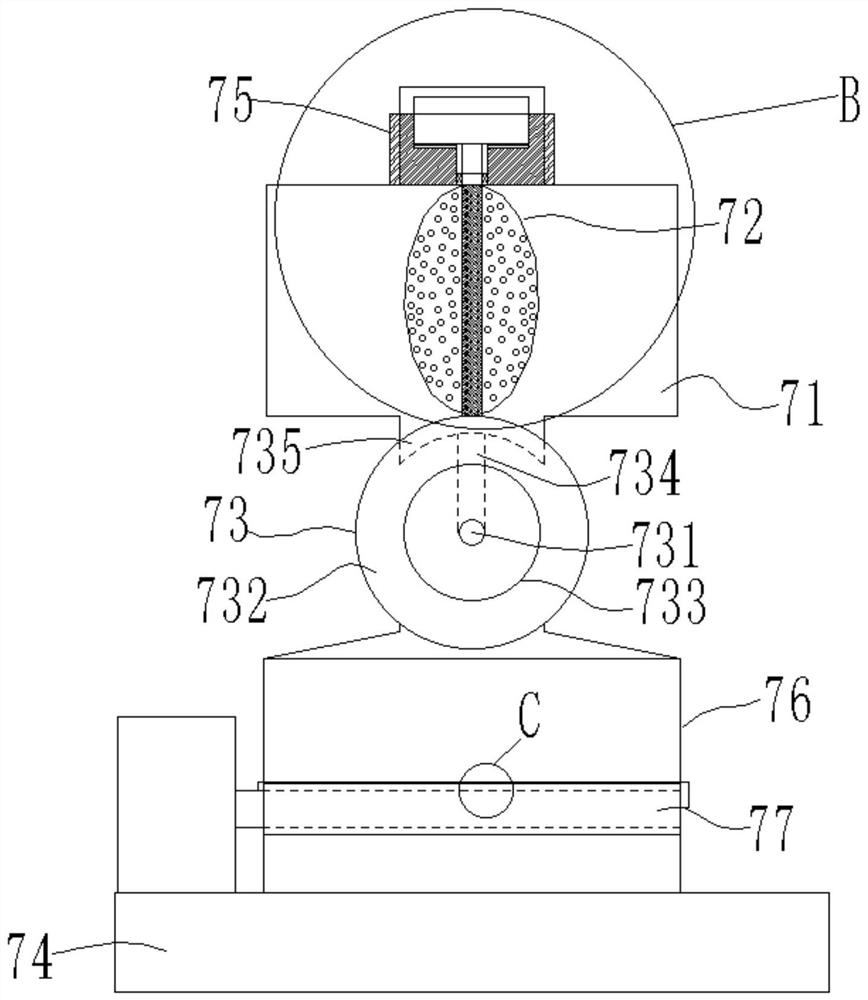

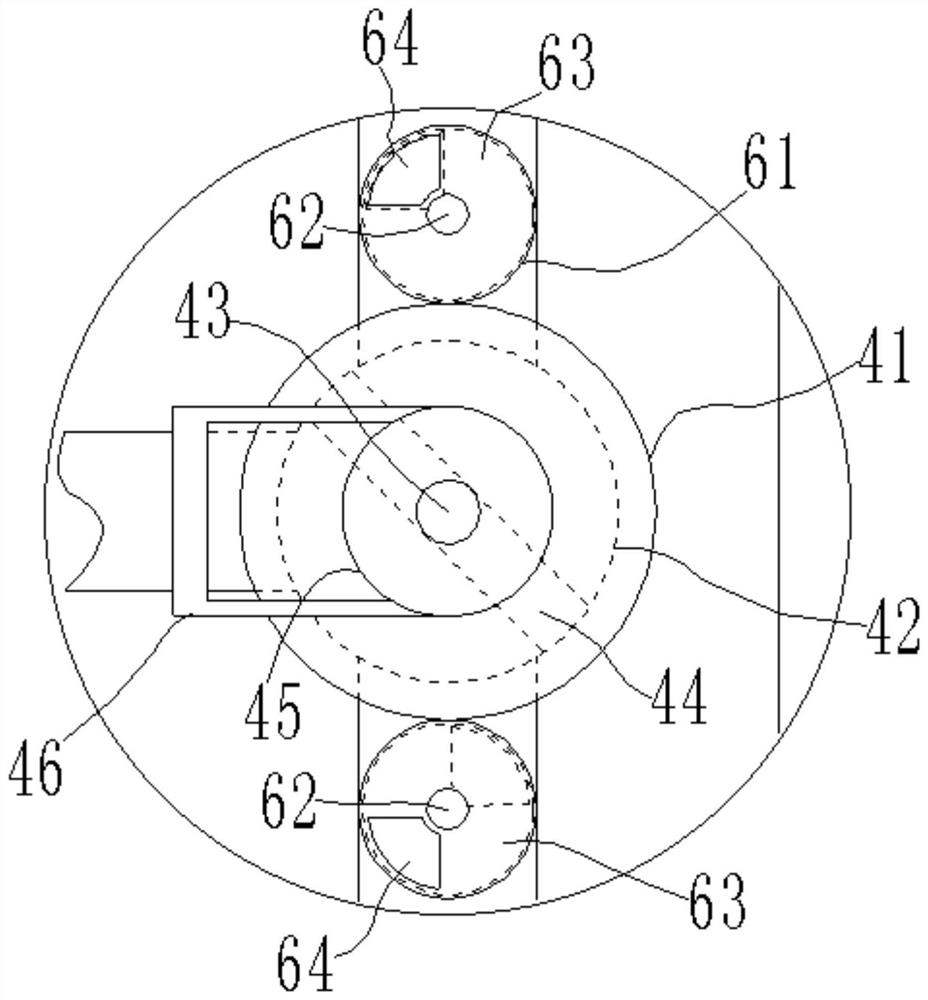

[0032] Such as figure 1 As shown, a tube turbid wastewater suspension treatment apparatus based on a YC magnetic separation process comprising an inlet pipe 1, a water pipe 2, a PLC controller 3, a retractable, and a flow pipe 4, a flow pipe 4, a fluid valve 4 of the left and right sides of the left and right sides are fixed, the front end of the diversion tube 5 is provided with a gas valve 6, and the air valve 6 is rotated over the air valve 61, and the guide valve 4 is rotated above the connection to the gear 2 41, the gear one 61 The gear two 41 is engaged, and the middle portion of each of the split tube 5 is provided with a magnetic power purification apparatus 7, and the inner side of the two split pipes 5 is provided with a material cartridge 8, and the tail of each shunt tube 5. It is provided with a power pump 9, and the rear end of the two split pipes 5 is fixedly connected to the flow pipe 2, and the PLC controller 3 is electrically connected to the flow of the flow va...

Embodiment 2

[0038] Such as figure 1 As shown, a tube turbid wastewater suspension treatment apparatus based on a YC magnetic separation process comprising an inlet pipe 1, a water pipe 2, a PLC controller 3, a retractable, and a flow pipe 4, a flow pipe 4, a fluid valve 4 of the left and right sides of the left and right sides are fixed, the front end of the diversion tube 5 is provided with a gas valve 6, and the air valve 6 is rotated over the air valve 61, and the guide valve 4 is rotated above the connection to the gear 2 41, the gear one 61 The gear two 41 is engaged, and the middle portion of each of the split tube 5 is provided with a magnetic power purification apparatus 7, and the inner side of the two split pipes 5 is provided with a material cartridge 8, and the tail of each shunt tube 5. It is provided with a power pump 9, and the rear end of the two split pipes 5 is fixedly connected to the flow pipe 2, and the PLC controller 3 is electrically connected to the flow of the flow va...

Embodiment 3

[0045] Such as figure 1 As shown, a tube turbid wastewater suspension treatment apparatus based on a YC magnetic separation process comprising an inlet pipe 1, a water pipe 2, a PLC controller 3, a retractable, and a flow pipe 4, a flow pipe 4, a fluid valve 4 of the left and right sides of the left and right sides are fixed, the front end of the diversion tube 5 is provided with a gas valve 6, and the air valve 6 is rotated over the air valve 61, and the guide valve 4 is rotated above the connection to the gear 2 41, the gear one 61 The gear two 41 is engaged, and the middle portion of each of the split tube 5 is provided with a magnetic power purification apparatus 7, and the inner side of the two split pipes 5 is provided with a material cartridge 8, and the tail of each shunt tube 5. It is provided with a power pump 9, and the rear end of the two split pipes 5 is fixedly connected to the flow pipe 2, and the PLC controller 3 is electrically connected to the flow of the flow va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com