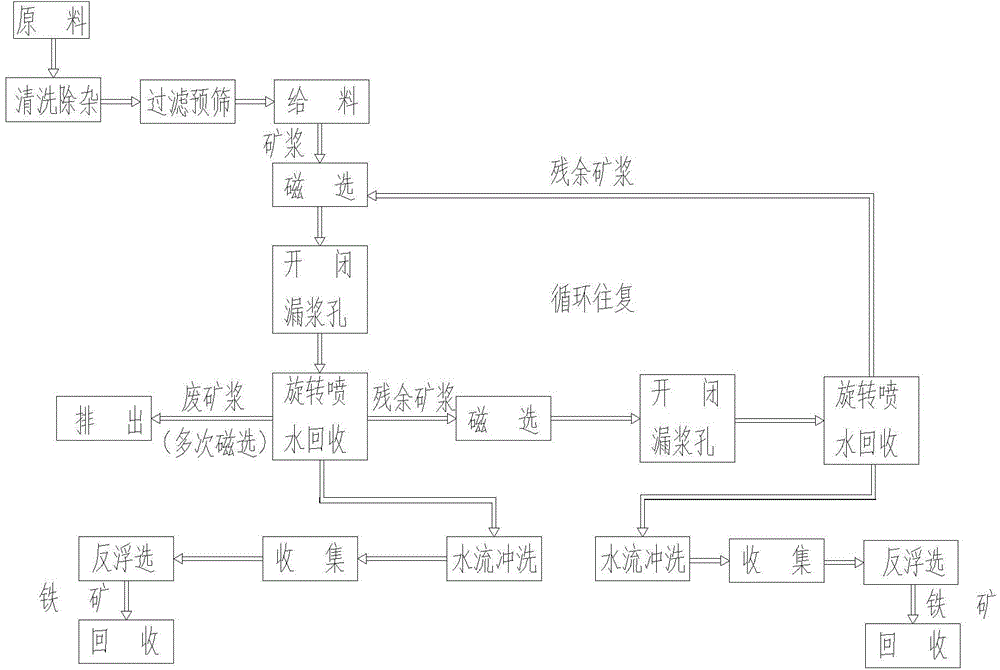

A kind of circulating wet magnetic separation method

A magnetic separation and wet technology, applied in wet separation, chemical instruments and methods, flotation, etc., can solve the problems of inconvenient management, large floor area, long process, etc., and achieve easy management, small floor space, The effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A circulating wet magnetic separation method, it comprises the following steps:

[0037] 1) Cleaning and removing impurities, wet pulp, cleaning and removing impurities first, and controlling the content of visible impurities in the pulp below 10%;

[0038] 2) Filtration and pre-screening, the pulp passes through 60-400 mesh sieve holes in advance to select finer particles of pulp;

[0039] 3) Feeding, injecting the mixed pulp into the magnetic separator;

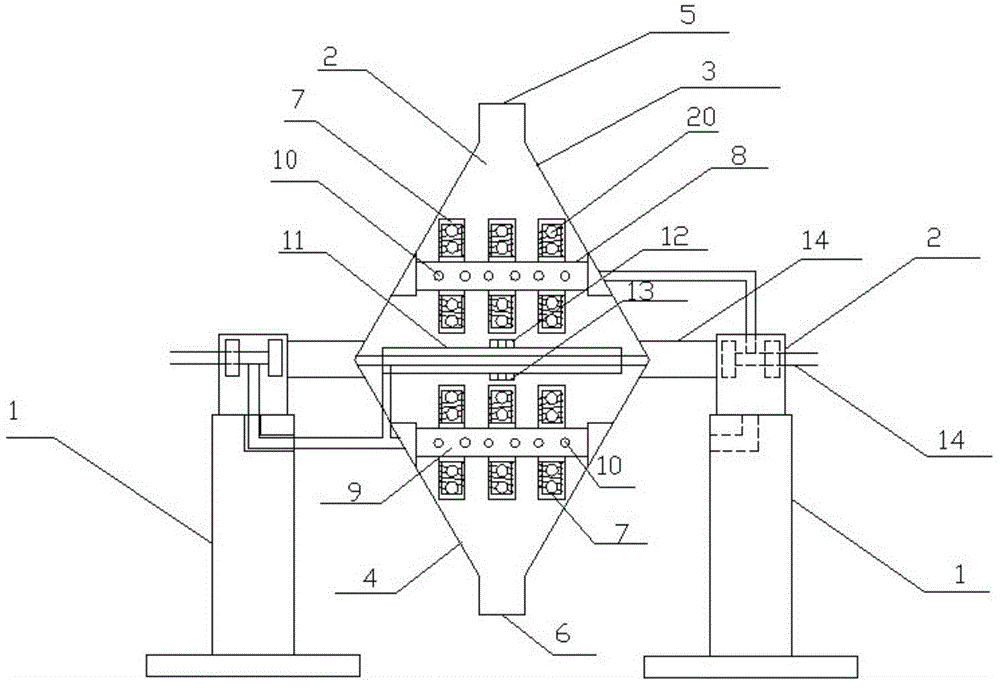

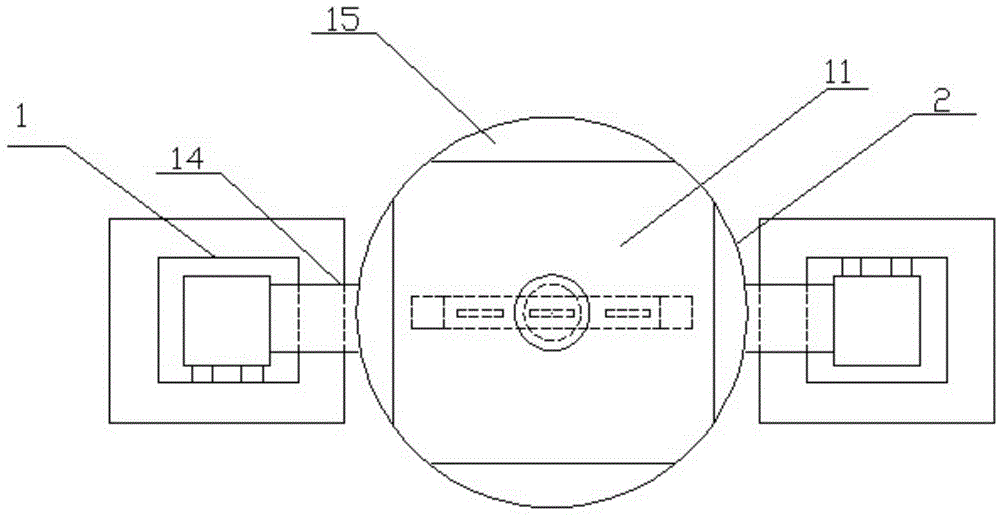

[0040] 4) For the first magnetic separation, the raw material enters the upper cone of the magnetic separator, the magnetic induction coil is energized and starts to rotate with the rotating spindle, and after 10-40 minutes of magnetic separation, the first magnetic separation ends;

[0041]5) Open and close the crescent-shaped slurry leakage hole for the first time, open the crescent-shaped slurry leakage hole between the edge of the water baffle and the inner wall of the magnetic separation cylinder, and discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com