Method for improving grade of ultra-lean ore

A high-grade, ultra-lean technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of difficult beneficiation and recovery, low content of useful elements, complex mineral composition, etc., to reduce the risk of shutdown, improve The grade of the ore and the effect of reducing the interference of slag such as impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Test sample and representative

[0036] The raw ore samples from the Cizhuqing Mine in Xiushuihe, Huili County weighed about 50 kilograms in total, and were mainly powder ore.

[0037] The incoming sample is dried, sieved, mixed and shrunk to obtain 10Kg (original ore) of a comprehensive sample of -3mm to 0mm for testing, and another 40Kg ore sample is prepared as a sample.

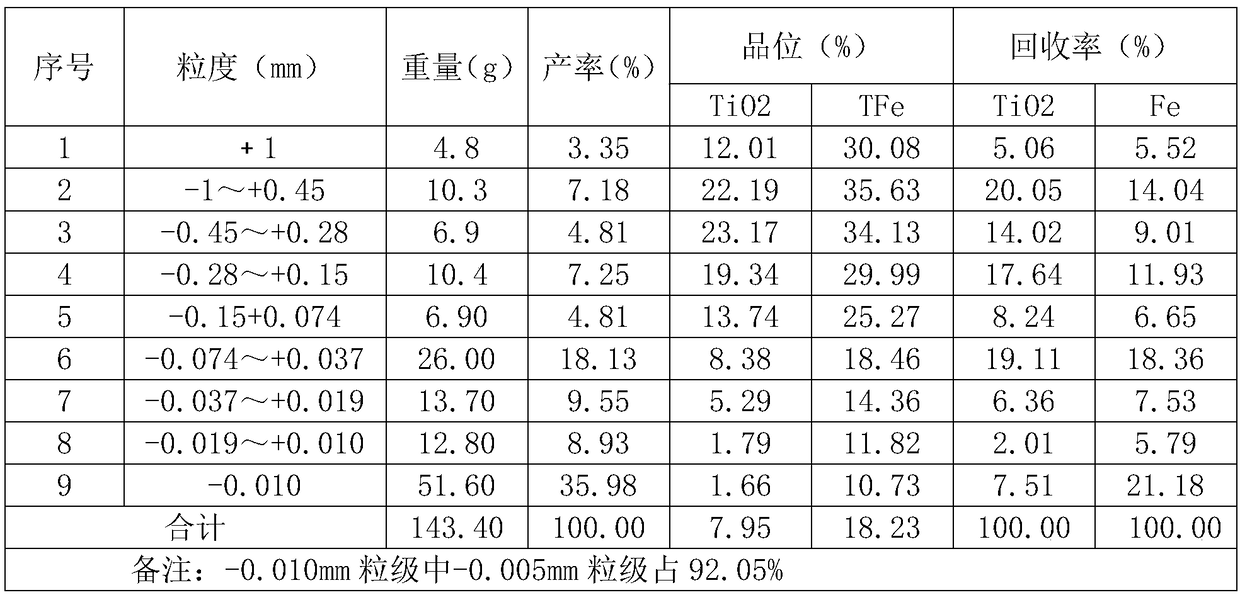

[0038] 2. Raw ore particle size analysis and metal distribution

[0039] Raw TiO 2 The grade was 7.95%, and the TFe grade was 18.23% (of which the mFe grade was 6.27%).

[0040] The particle size of the raw ore is analyzed, and the +0.037mm particle size is screened, and the -0.037mm particle size is analyzed by water. The analysis results are shown in Table 1.

[0041] Table 1 Results of particle size analysis of raw ore

[0042]

[0043] The results of particle size analysis in Table 1 show that the raw ore TiO 2 The grade is 7.95%, the raw ore contains heavy mud, and the content of -...

Embodiment 2

[0054] 1. Material properties

[0055] Titanium magnetite, of which -74μm72.59%, -37μm54.46%.

[0056] 2. Test requirements

[0057] The concentration of the feed is 15%; desliming according to 74 μm and 37 μm respectively, the grade test data are shown in Table 1.

[0058] 3. Test results and discussion

[0059] (1) Composition of incoming material particle size

[0060] Granularity

-74μm / %

-45μm / %

72.59

54.46

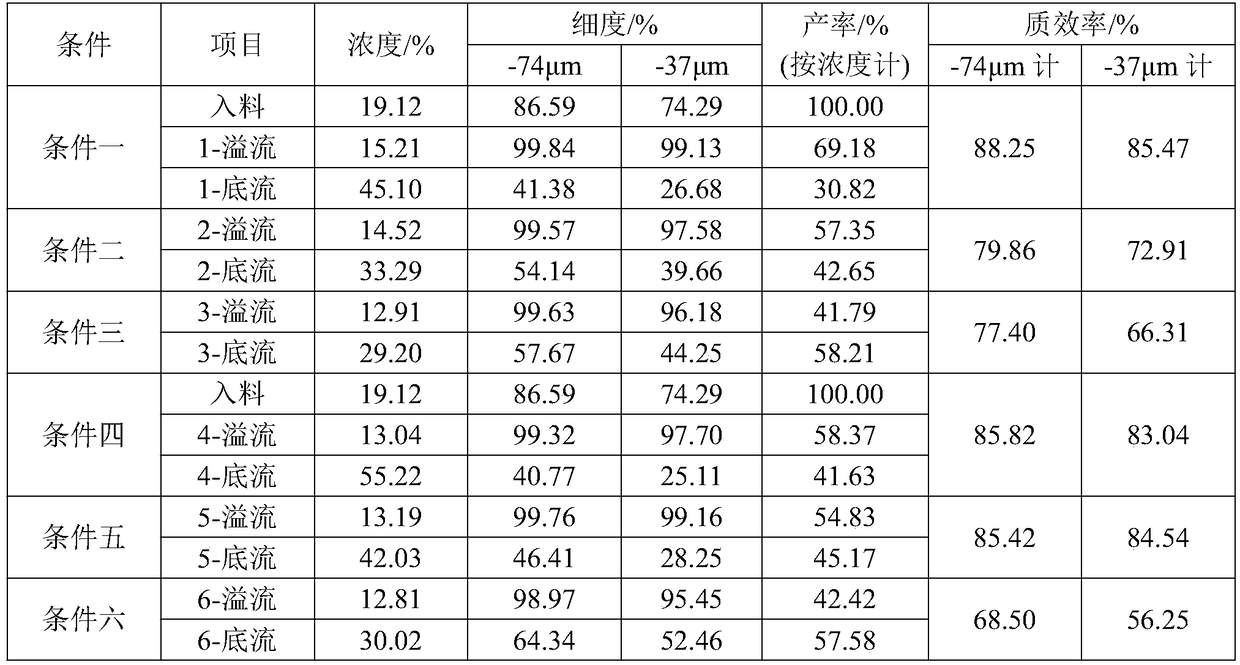

[0061] (2) Cyclone classification test data

[0062] 1) Cyclone desliming test

[0063]

[0064] 2) Metal grade analysis

[0065]

[0066] (3) Data analysis

[0067] 1) FX150-A cyclone bottom flow rate can be adjusted in a wider range, and the classification efficiency is higher. Both FX150-A and FX150-B cyclones can achieve better desliming effect, but the bottom flow rate of FX150-A cyclone is in the range of 30-58%, while the bottom flow rate of FX150-B cyclone is 41%. ~58% range. Under the condition...

Embodiment 3

[0073] The FX150-A cyclone determined in Examples 1 and 2 was used for desliming according to condition three.

[0074] 1) The raw ore is subjected to open-circuit rubbing and washing treatment with a ball mill, and the obtained ore pulp is subjected to desliming treatment to obtain desliming ore pulp;

[0075] 2) The deslimed ore slurry is ground to obtain a first-level deslimed ore slurry; the particle size of the ore after the grinding is analyzed to be -10 μm78.3%;

[0076] 3) The first-stage desliming slurry is subjected to first-stage magnetic separation to obtain coarse concentrate, and the tailings are discarded; the magnetic induction intensity of the first-stage magnetic separation is 0.1T;

[0077] 4) The coarse concentrate is ground to obtain secondary desliming slurry; the particle size of the ore after grinding is -10μm85% by analysis;

[0078] 5) The secondary desliming slurry is subjected to secondary magnetic separation to obtain iron coarse concentrate and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com