Wall painting device for constructional engineering

A technology for construction engineering and painting, which is applied in construction, building construction, mixers with rotary stirring devices, etc., can solve problems such as difficulty in popularization and application, high labor intensity, and increased labor workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

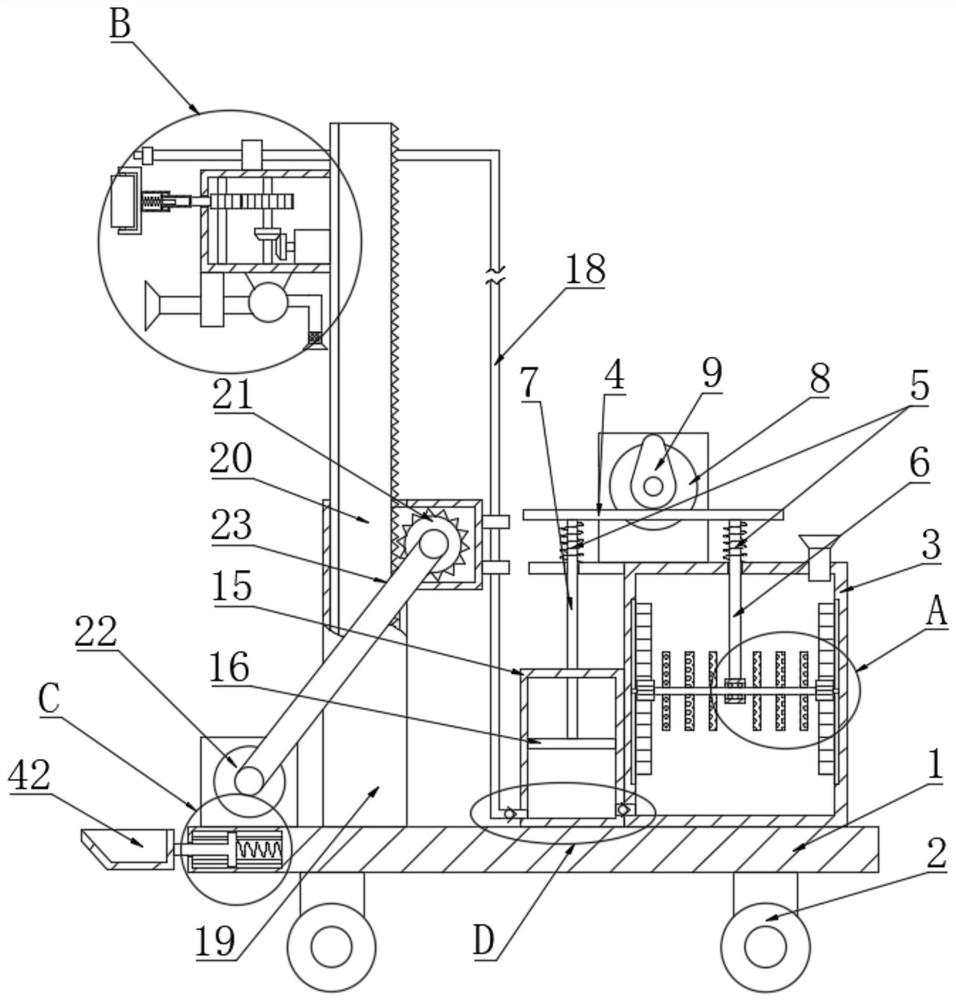

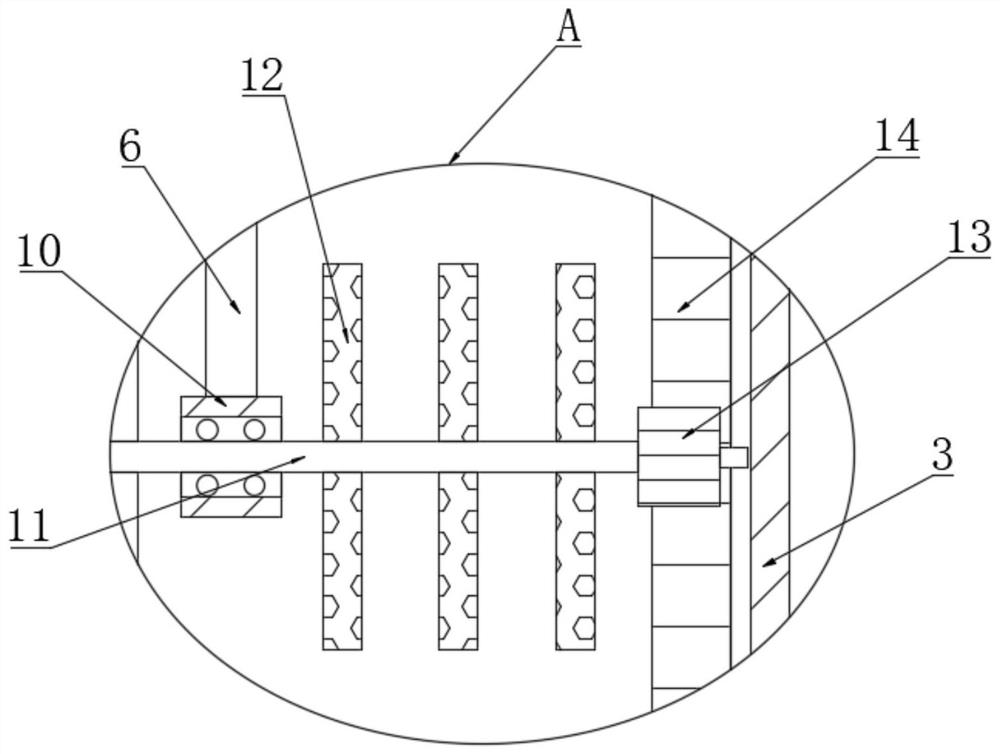

[0030] see Figure 1 to Figure 7 , a wall painting device for construction engineering, comprising a base 1, the base 1 is provided with a paint storage box 3 and a material delivery box 15, and a stirring assembly is arranged in the paint storage box 3, and the stirring assembly It includes a first rotating shaft 11, a stirring blade 12, a first gear 13 and a rack 14, the first gear 13 is connected to the rack 14, and the first rotating shaft 11 is rotatably connected to the bearing housing 10 and the first connecting shaft through a bearing. On the rod 6, the second connecting rod 7 and the piston plate 16 are arranged in the conveying box 15 to facilitate pulling. There is a rotary drive assembly, which includes a first motor 8 , a cam 9 , a push plate 4 and a first spring 5 , and the delivery box 15 is connected with a spray nozzle 24 for painting through a second connecting pipe 18 .

[0031] Further, the top of the stucco paint storage box 3 is provided with a feed hopp...

Embodiment 2

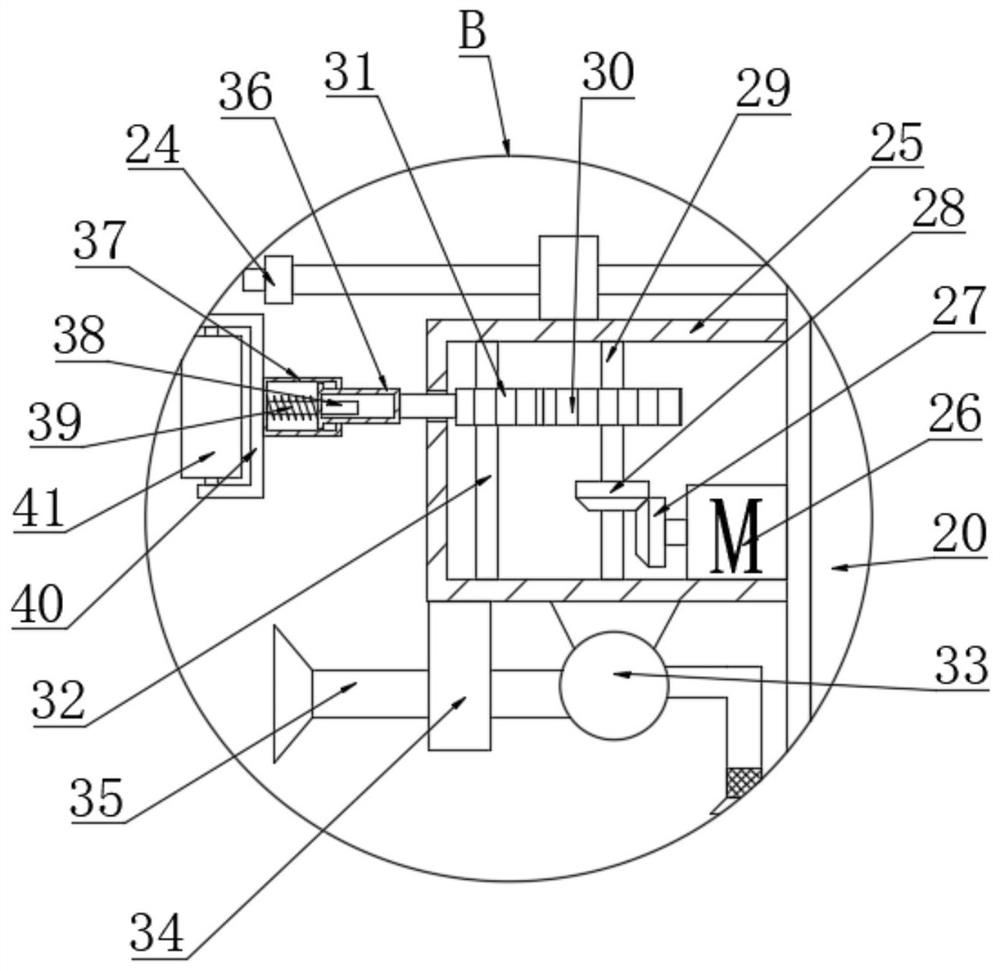

[0038] see Figure 1 to Figure 7 , a wall painting device for construction engineering, including a base 1 and a spray head 24, a paint roller 41 and a fixed frame 40 for easy painting are arranged below the spray head 24, and a spring assembly is connected to one side of the fixed frame 40, The spring assembly includes a sleeve rod 36, a sleeve 37, a first slide rod 38 and a second spring 39, the sleeve 37 is slidably connected to the sleeve rod 36, and one side of the sleeve rod 36 is connected with a horizontal rotation drive Assemblies, the horizontal rotation drive assembly includes a semi-circular gear 31, a third gear 30 and a third motor 26, the semi-circular gear 31 and the third gear 30 are rotationally connected to the gearbox 25 through the third rotating shaft 32 and the second rotating shaft 29 respectively Inside, a drying assembly is arranged below the gear box 25, the drying assembly includes a blower 33, a heating box 34 and an air outlet pipe 35, the gear bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com