Fresh-keeping gas replacement device and method

A fresh-keeping gas and film device technology, applied in the direction of pressurized/gasified packaging, packaging, transportation packaging, etc., can solve problems such as being unfavorable to safe and hygienic production, increase manufacturing costs, and reduce purchasing power, and achieve upfront costs and maintenance costs. The effect of low cost, lower purchase cost and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

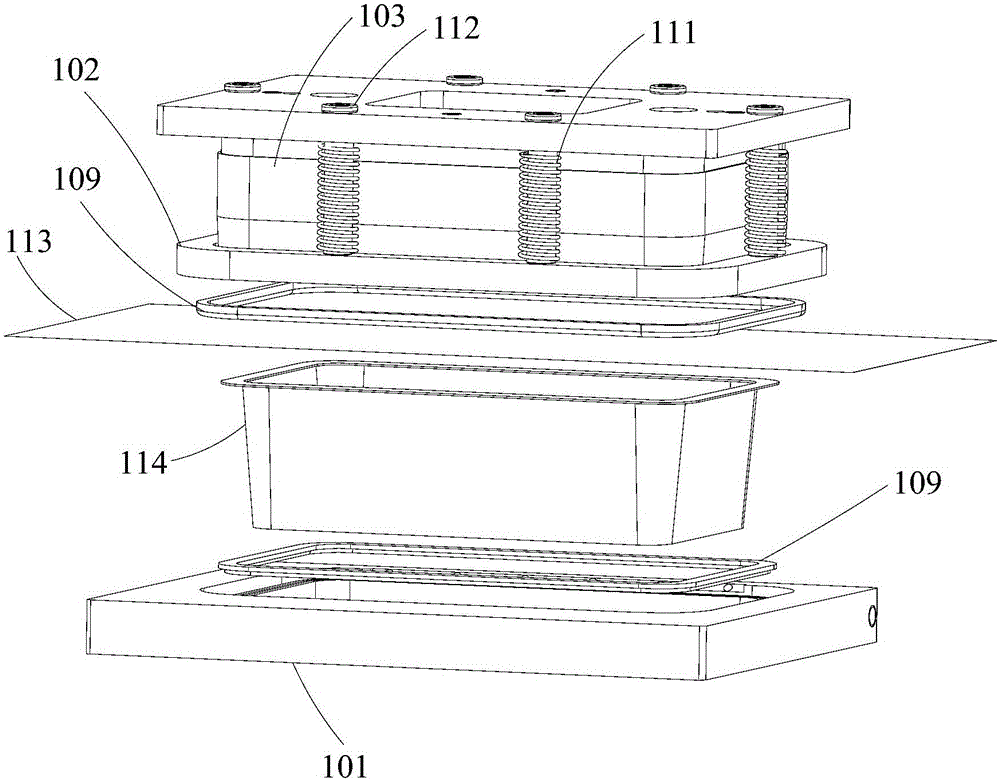

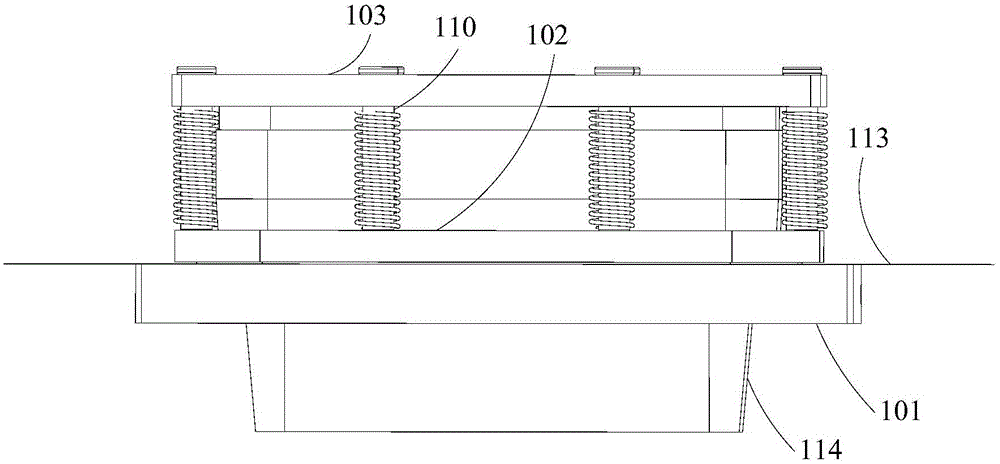

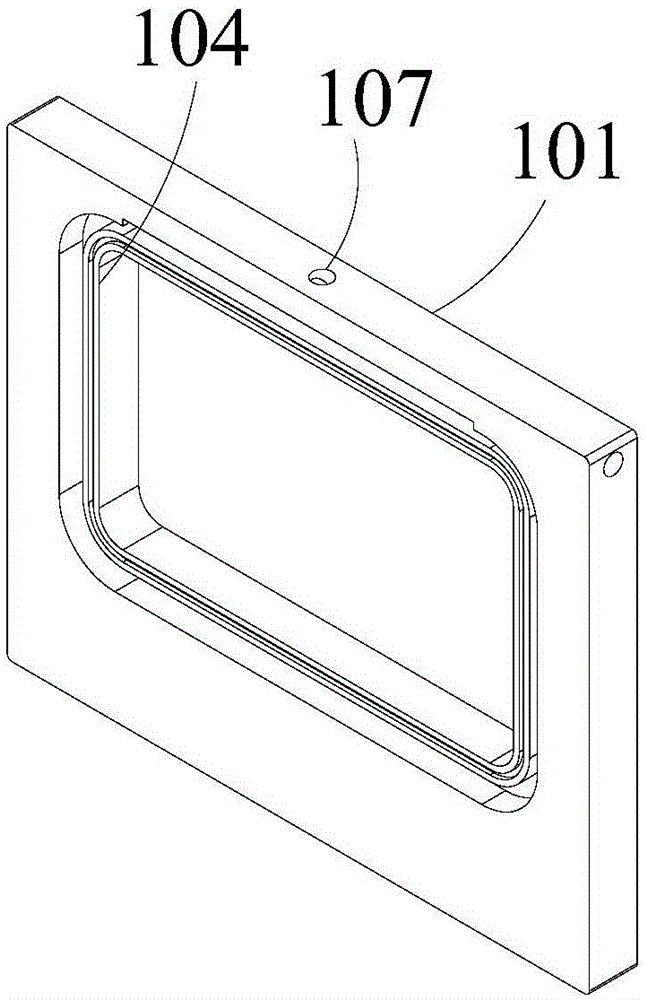

[0074]A fresh-keeping gas replacement device, comprising a positioning mold 101, a pressing plate 102 and a sealing film cutting device 103; the positioning mold 101 is provided with a positioning cavity 104 for placing a packaging box 114, and the positioning mold 101 is also provided with an inlet connecting the positioning cavity 104 The air hole 105 and the exhaust hole 106; the air inlet 105 includes a connected air inlet 107 and an air outlet 108, the air inlet 107 is arranged on the outside of the positioning mold 101, and the air outlet 108 is arranged on the side wall of the positioning cavity 104. There are 6 air outlets 108, and the 6 air outlets 108 are arranged in a "one" shape, and are evenly spaced on one of the side walls of the positioning cavity 104, and the side wall is inclined upward, so that the air outlet 108 is inclined upward. There are also 6 exhaust holes 106, which are evenly spaced on the other side wall of the positioning cavity 104. One end of the...

Embodiment 2

[0078] A fresh-keeping gas replacement method, comprising the steps of:

[0079] The packing box is placed in the positioning cavity 104 of the positioning mold 101, so that the edge of the positioning mold 101 is bonded to the sealing ring 109 in the positioning cavity 104;

[0080] Cover a layer of film 113 on the upper surface of the positioning mold 101;

[0081] The film 113 is pressed on the upper surface of the positioning mold 101 by the pressing plate 102;

[0082] Through the air inlet 105 arranged on the positioning mold 101, fresh-keeping gas is passed into the packaging box, so that the fresh-keeping gas is obliquely entered in the packaging box and forms a vortex-shaped air flow, and the original gas in the packaging box is discharged through the exhaust hole 106;

[0083] The sealing and film cutting mechanism is used to seal and cut the packaging box.

[0084] The fresh-keeping gas replacement device and method obtained through the above design can quickly fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com