Building brick cutting machine

A brick cutting machine and construction technology, applied in stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of easy hand injury and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

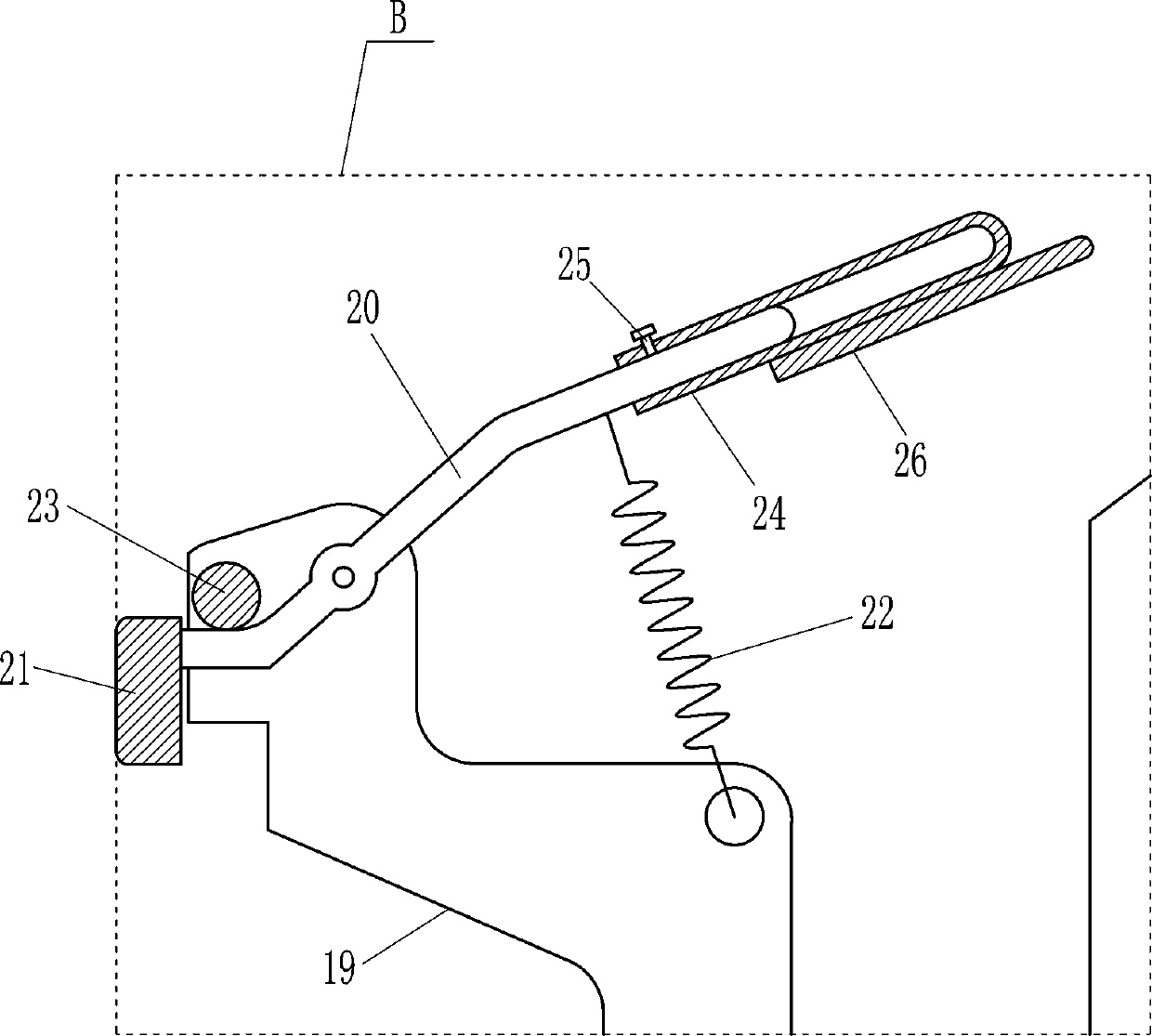

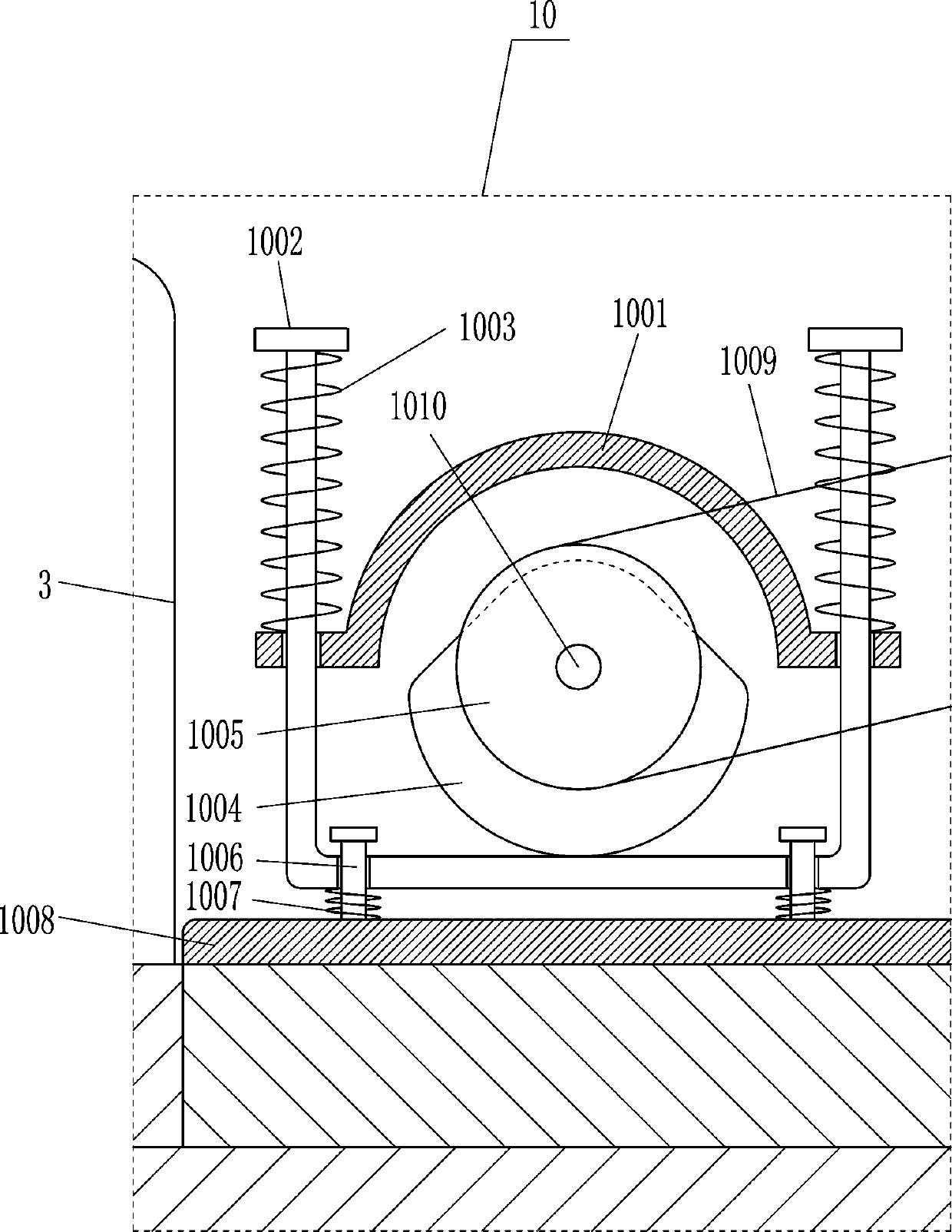

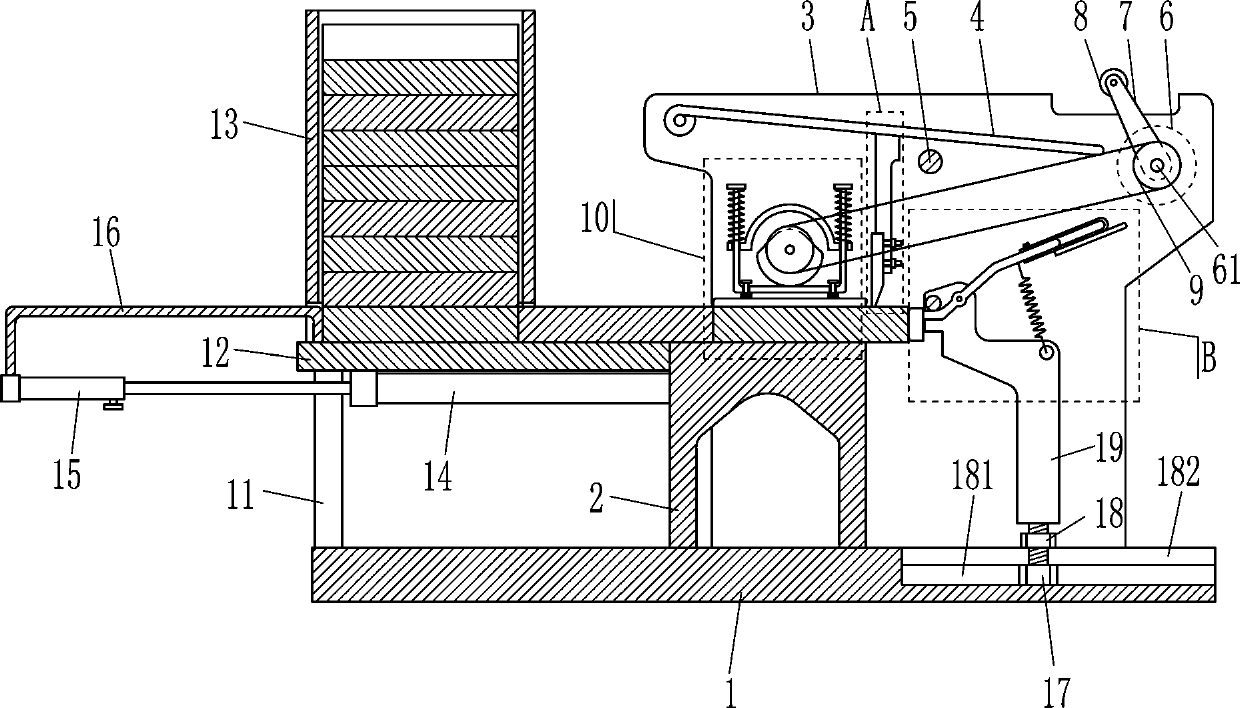

[0017] A construction brick cutter, such as Figure 1-3 As shown, it includes a base 1, a workbench 2, a first mounting plate 3, a spring plate 4, a mounting rod 401, a press knife 402, a first limit block 5, a motor 6, a first rotating shaft 61, a swing rod 7, and a roller 8. The first belt wheel 9 and the pressing mechanism 10, the top middle of the base 1 is fixedly connected with a workbench 2 where bricks can be placed, the base 1 is connected to the workbench 2 by welding, and the top right rear of the base 1 is fixed Connected to the first mounting plate 3, the first mounting plate 3 is located on the back side of the workbench 2 in contact with it. The upper left part of the front side of the first mounting plate 3 is provided with a pressing mechanism 10 that can compress bricks. Located above the workbench 2, the upper right part of the first mounting plate 3 is rotatably connected with a first rotating shaft 61. The front end of the first rotating shaft 61 is equipped...

Embodiment 2

[0019] A construction brick cutting machine, such as Figure 1-3 As shown, it includes a base 1, a workbench 2, a first mounting plate 3, a spring plate 4, a mounting rod 401, a press knife 402, a first limit block 5, a motor 6, a first rotating shaft 61, a swing rod 7, and a roller 8. The first belt wheel 9 and the pressing mechanism 10, the middle of the top of the base 1 is fixed with a workbench 2 where bricks can be placed, and the first mounting plate 3 and the first mounting plate 3 are fixed at the right rear of the top of the base 1 Located on the back side of the workbench 2 in contact with it, the upper left part of the front side of the first mounting plate 3 is provided with a pressing mechanism 10 that can compact the bricks. The pressing mechanism 10 is located above the workbench 2, and the right part of the first mounting plate 3 The upper side is rotatably connected with a first rotating shaft 61. A first pulley 9 is installed at the front end of the first rota...

Embodiment 3

[0022] A construction brick cutting machine, such as Figure 1-3 As shown, it includes a base 1, a workbench 2, a first mounting plate 3, a spring plate 4, a mounting rod 401, a press knife 402, a first limit block 5, a motor 6, a first rotating shaft 61, a swing rod 7, and a roller 8. The first belt wheel 9 and the pressing mechanism 10, the middle of the top of the base 1 is fixed with a workbench 2 where bricks can be placed, and the first mounting plate 3 and the first mounting plate 3 are fixed at the right rear of the top of the base 1 Located on the back side of the workbench 2 in contact with it, the upper left part of the front side of the first mounting plate 3 is provided with a pressing mechanism 10 that can compact the bricks. The pressing mechanism 10 is located above the workbench 2, and the right part of the first mounting plate 3 The upper side is rotatably connected with a first rotating shaft 61. A first pulley 9 is installed at the front end of the first rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com