Polyester resin with high hardness and high storage stability for 60/40 mixed powder and preparation method thereof

A polyester resin, high hardness technology, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as inaccessibility, agglomeration, and high activity of carboxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of polyester resin for 60 / 40 mixed powder with high hardness and high storage stability includes the following steps:

[0047] (1) Add neopentyl glycol and 2-methyl-2,4-pentanediol into the reactor, mix well and heat and melt at 140°C;

[0048] (2) Add terephthalic acid and 2,3-dihydroxysuccinic acid to the reactor, and add 0.1% of the total mass of the resin as a catalyst at the same time, and gradually increase the temperature to 190°C under the protection of nitrogen. ℃, the heating rate is controlled at 15℃ / h, and then the temperature is kept for 3 hours. When the effluent is not obvious, add 2,2'-diphthalic acid, and then continue to heat up to 220℃ at 10℃ / h, keep the temperature for 2 hours, wait When there is no obvious distillate, add tris(2-hydroxyethyl) isocyanurate to continue the reaction, slowly increase the temperature to 240°C at 8°C / h, and continue the reaction until the acid value of the polyester resin is less than 35mgKOH / g ;

[0049...

Embodiment 2

[0053] In (2), the reaction conditions are as follows:

[0054] Add terephthalic acid and 2,3-dihydroxysuccinic acid to the reaction kettle, and at the same time add 0.1% of the total mass of the resin monobutyl tin oxide as a catalyst, and gradually increase the reaction temperature to 185°C under the protection of nitrogen. The speed is controlled at 15℃ / h, and then the temperature is kept for 2.5 hours. When the effluent is not obvious, add 2,2'-diphthalic acid, and then continue to heat up to 215℃ at 10℃ / h, and keep for 1.5 hours. When the distillate is obvious, add the formula amount of tris(2-hydroxyethyl) isocyanurate to continue the reaction, slowly increase the temperature to 235°C at 9°C / h, and continue the reaction until the acid value of the polyester resin is less than 35mgKOH / g up to.

Embodiment 3

[0055] The reaction conditions of Example 3 and Example 4 are the same as those of Example 1.

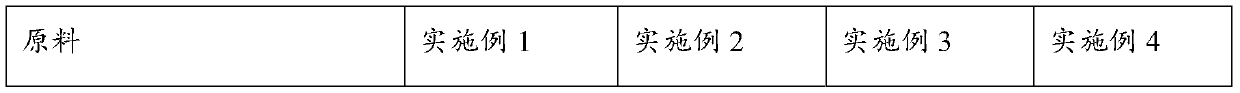

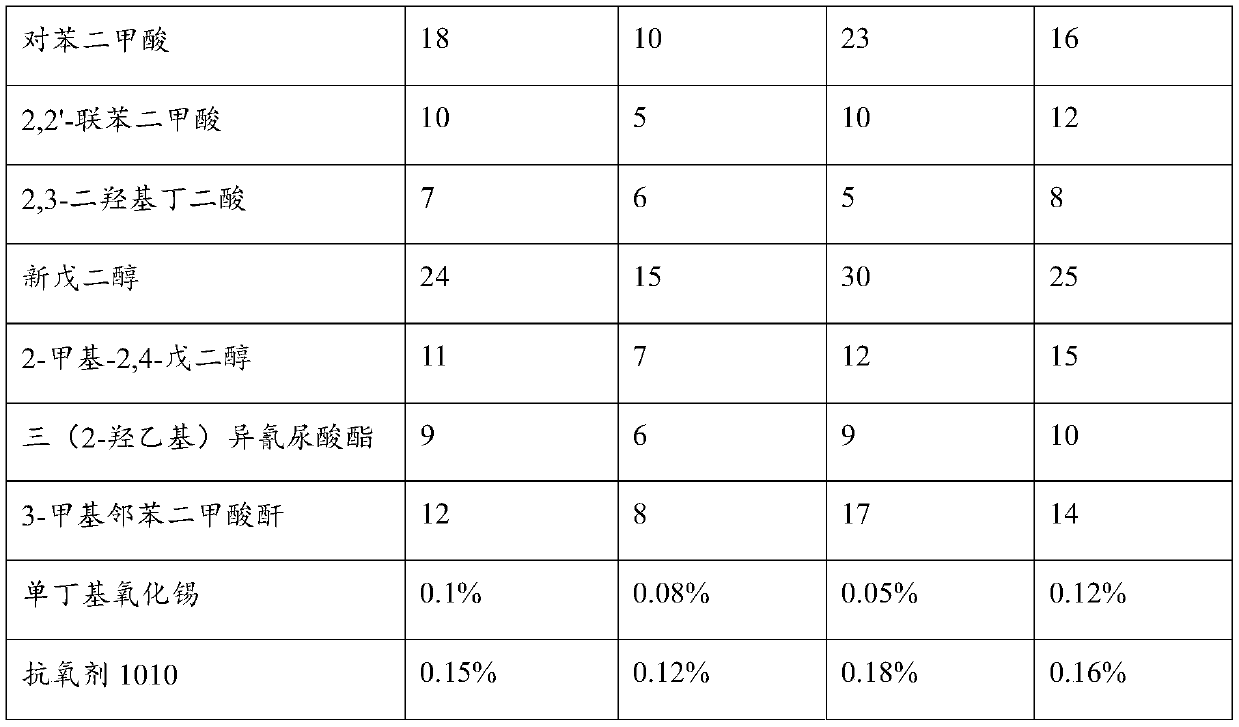

[0056] Table 1 The mole fraction of each raw material in Examples 1 to 4

[0057]

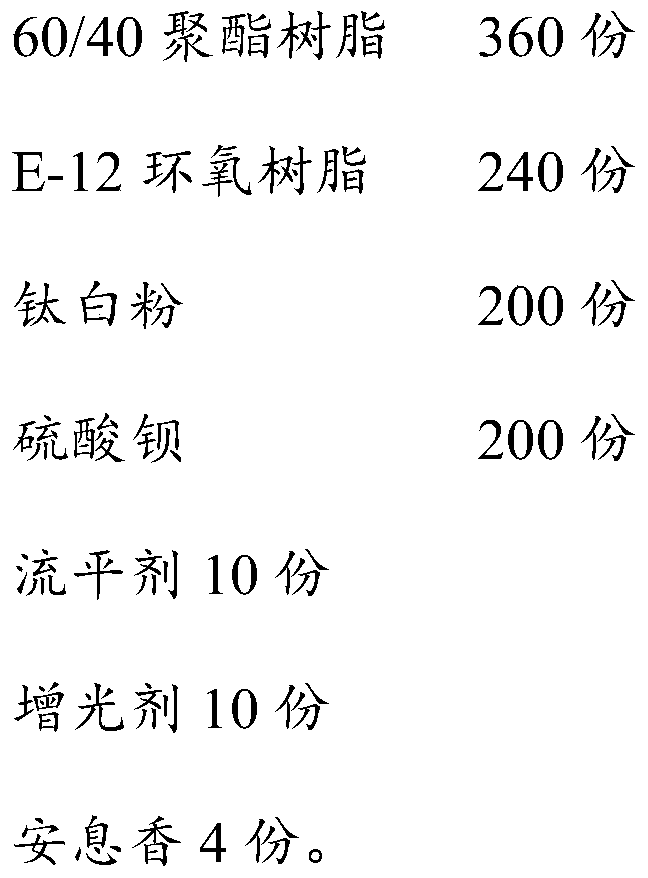

[0058]

[0059] Regarding the present invention, in the process of obtaining the best solution, the inventor also conducted the following experiments, specifically:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com