Device and method for in-situ laser drilling sampling and solder sealing of small pipe

A laser drilling and welding sealing technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor observation effect of lighting source, not enough to solve the problems of microhole processing-sampling-sealing, lack, etc. , to achieve the effect of ensuring continuous reliable service, large aspect ratio and small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

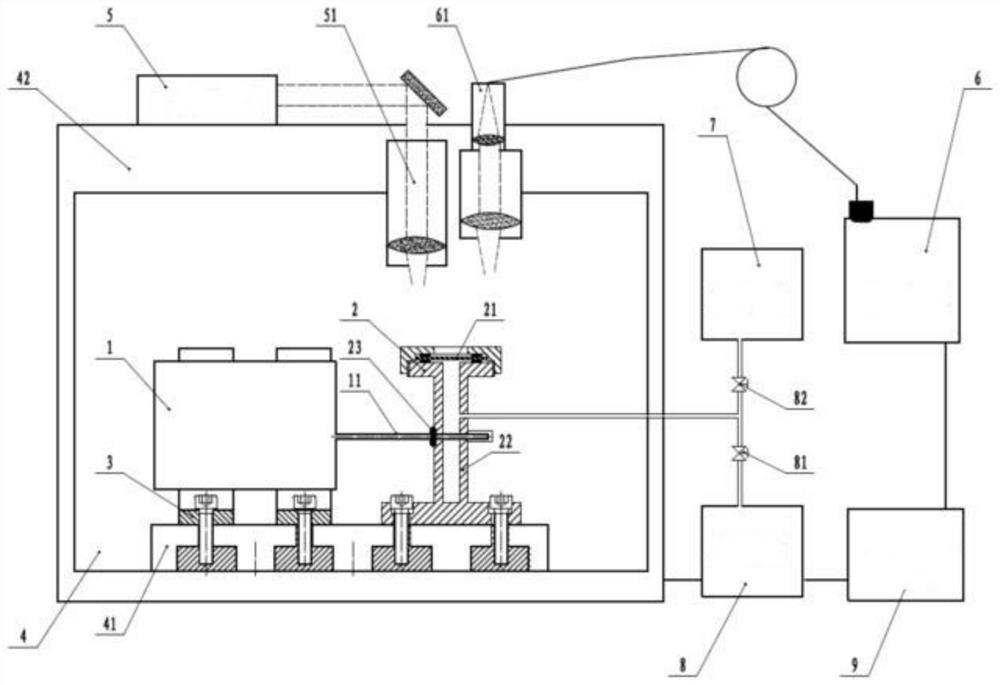

[0043] like figure 1 As shown, in this embodiment, a device for in-situ laser drilling, sampling and sealing of small tubes is specifically provided, aiming to realize the technical integration of laser drilling, sampling and sealing through this device, the device includes:

[0044] ①Sampling container

[0045] The inside of the sampling container 2 is hollow and the inside is a sealed inner cavity. In this embodiment, the sampling container 2 includes: a container cylinder 22, a container cover adapted to the container cylinder 22, and the container cylinder 22 The side wall of the side wall is provided with an insertion hole 23 that is tightly fitted with the sampling tube 11. When the sampling tube 11 is inserted into the insertion hole 23, there should be good sealing between the sampling tube 11 and the wall of the insertion hole 23, and the container cylinder The side wall of the body 22 is provided with an accommodating cavity opposite to the insertion hole 23, so as ...

Embodiment 2

[0063] In this embodiment, a method for in-situ laser drilling, sampling and sealing of small tubes is also provided. This method is applied to the device for in-situ laser drilling, sampling and sealing of small tubes described in Example 1 above. In an embodiment, the specification of the sampling tube 11 is Φ3mmx1mm, and its material is austenitic stainless steel. The method includes:

[0064] S1: degreasing the outer wall of the sampling tube 11 and the inner wall of the sampling container 2, in this embodiment, acet(butyl) ketone degreasing the outer wall of the metal sampling tube 11 and the inner wall of the sampling container 2, and then use Wipe with alcohol to remove surface moisture, and dry with hot air;

[0065] S2: Insert the sampling tube 11 into the body of the sampling container 2 and seal the assembly of the sampling tube 11 and the sampling container 2, and fix the product 1 with the sampling tube 11 and the sampling container 2 on the workbench 4 through th...

Embodiment 3

[0071] In this embodiment, another method for in-situ laser drilling, sampling and sealing of small tubes is provided. This method is applied to the device for in-situ laser drilling, sampling and sealing of small tubes described in Example 1 above. In this embodiment, the specification of the sampling tube 11 is Φ4mmx1.2mm, and the material is austenitic stainless steel. The method includes:

[0072] S1: degreasing the outer wall of the sampling tube 11 and the inner wall of the sampling container 2, in this embodiment, acet(butyl) ketone degreasing the outer wall of the metal sampling tube 11 and the inner wall of the sampling container 2, and then use Wipe with alcohol to remove surface moisture, and dry with hot air;

[0073]S2: Insert the sampling tube 11 into the body of the sampling container 2 and seal the assembly of the sampling tube 11 and the sampling container 2, and fix the product 1 with the sampling tube 11 and the sampling container 2 on the workbench 4 throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com