Method for changing wettability of surface of metallic nickel through hydrofluoric acid etching

A wettability, metal nickel technology, applied in the field of changing the surface wettability of metal nickel, to achieve the effect of high cost performance, convenient operation, low requirements for raw materials and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

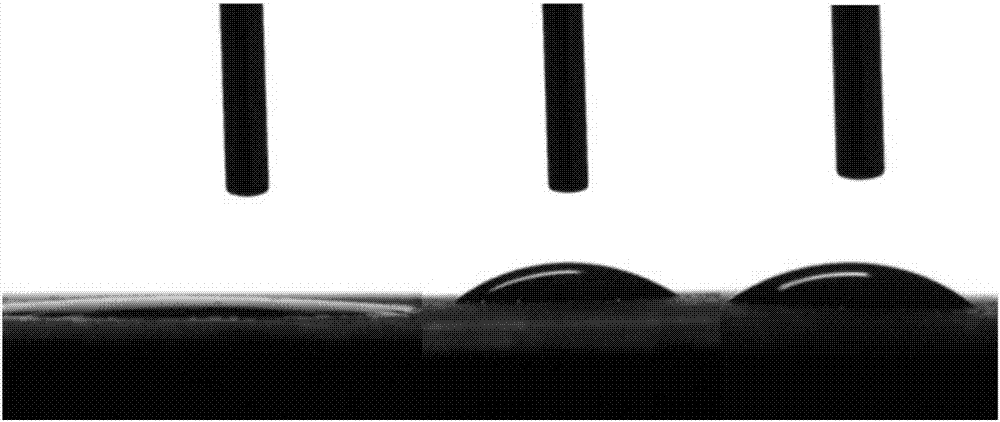

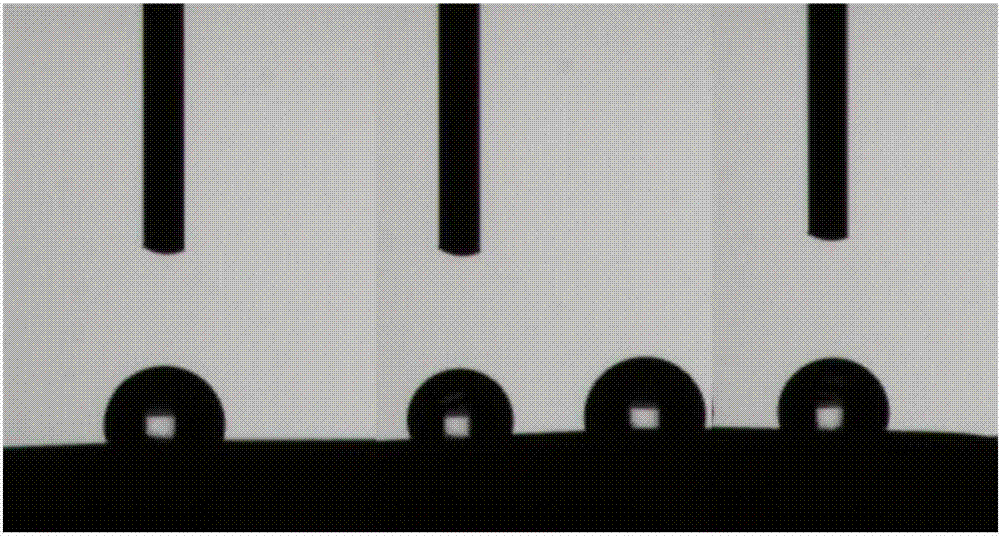

[0033] Such as figure 1 As shown, the present invention provides a method for changing the wettability of the metal nickel surface, which mainly adopts a hydrofluoric acid etching method, combined with a cleaning process, to change the wettability of the metal nickel surface and improve its hydrophobicity. The main process of the present invention is as follows:

[0034] (1)Using ultrasonic cleaning method to clean the metal nickel surface to remove the oil stains and adsorbed impurities on the metal nickel sheet surface. The specific cleaning process is:

[0035] (a) Use absolute ethanol to ultrasonically clean the surface of the metal nickel sheet for more than 10 minutes;

[0036] (b) Take out the metal nickel sheet and rinse it with absolute ethanol three times, and then soak the metal nickel sheet in 30°C, 1M NaOH solution for more than 30 minutes;

[0037] (c) Ultrasonic the metal nickel sheet in a 1M NaOH solution at 30°C for more than 30 minutes;

[0038] (d) Take out the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com