Coating composition and method for forming coating film using same

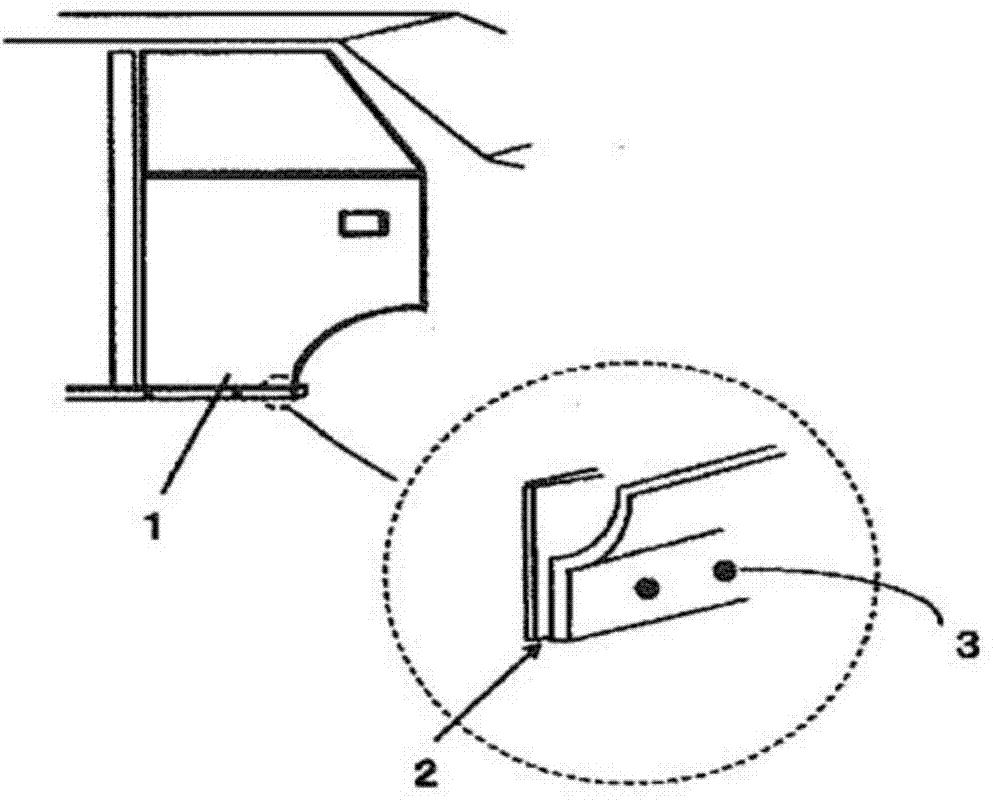

A composition and coating technology, used in electrophoretic coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of insufficient end-face corrosion inhibition and reduced finishing properties, and achieve excellent edge corrosion inhibition, The effect of improving corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0128] The following examples are given to describe the present invention in more detail. In addition, "part" and "%" mean "part by mass" and "% by mass" unless otherwise indicated.

[0129] Manufacture of Amino-Containing Modified Epoxy Resin (A)

manufacture example 1

[0130] Production example 1 Production example of matrix resin No. 1 (for example)

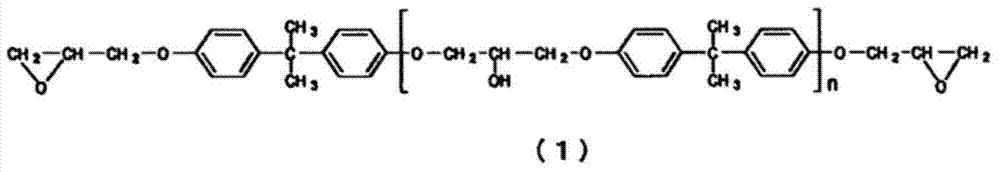

[0131] 1,000 parts of jER828EL (Note 1), 400 parts of bisphenol A, and 0.2 parts of dimethylbenzylamine were added to the flask, and reacted at 130° C. until the epoxy equivalent reached 750.

[0132] Next, 100 parts of ε-caprolactone and 0.05 part of tetrabutoxytitanium were added, the temperature was raised to 170° C., and the mixture was reacted at 170° C. for 4 hours.

[0133] Next, 100 parts of Placcel 205 (note 2), 140 parts of diethanolamine, and 65 parts of ketimide (purity 84%) obtained by using methyl isobutyl ketone of diethylenetriamine were added to this substance, and at 120 After reacting at °C for 4 hours, 400 parts of ethylene glycol monobutyl ether was added to obtain matrix resin No. 1 with an amine value of 56 and a resin solid content of 80%.

[0134] (Note 1) jER828EL: manufactured by Japan Epoxy Resin Co., Ltd., trade name, epoxy resin, epoxy equivalent 190, number aver...

manufacture example 2

[0136] Production example 2 Production example of base resin No. 2 (for example)

[0137] 1,000 parts of jER828EL (Note 1), 400 parts of bisphenol A, and 0.2 parts of dimethylbenzylamine were added to the flask, and reacted at 130° C. until the epoxy equivalent reached 750.

[0138] Next, 100 parts of ε-caprolactone and 0.05 part of tetrabutoxytitanium were added, the temperature was raised to 170° C., and the mixture was reacted at 170° C. for 4 hours.

[0139] Next, 100 parts of Placcel305 (Note 3), 140 parts of diethanolamine, and 65 parts of ketimide (purity 84%) of diethylenetriamine were added to this substance, and after reacting at 120° C. for 4 hours, ethyl alcohol was added. 400 parts of diol monobutyl ether were used to obtain matrix resin No. 2 with an amine value of 56 and a resin solid content of 80%.

[0140] (Note 3) Placcel305: Daicel Chemical Industries company make, brand name, polycaprolactone polyol compound (corresponds to the compound represented by sai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com