A kind of highly dispersed modified graphene oxide, its preparation method and anti-corrosion coating

A technology of anti-corrosion coatings and oxidized stones, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor dispersion and acid and alkali resistance, difficult dispersion stability of graphene, and complicated preparation process. To achieve the effect of long service life, enhanced dispersion and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

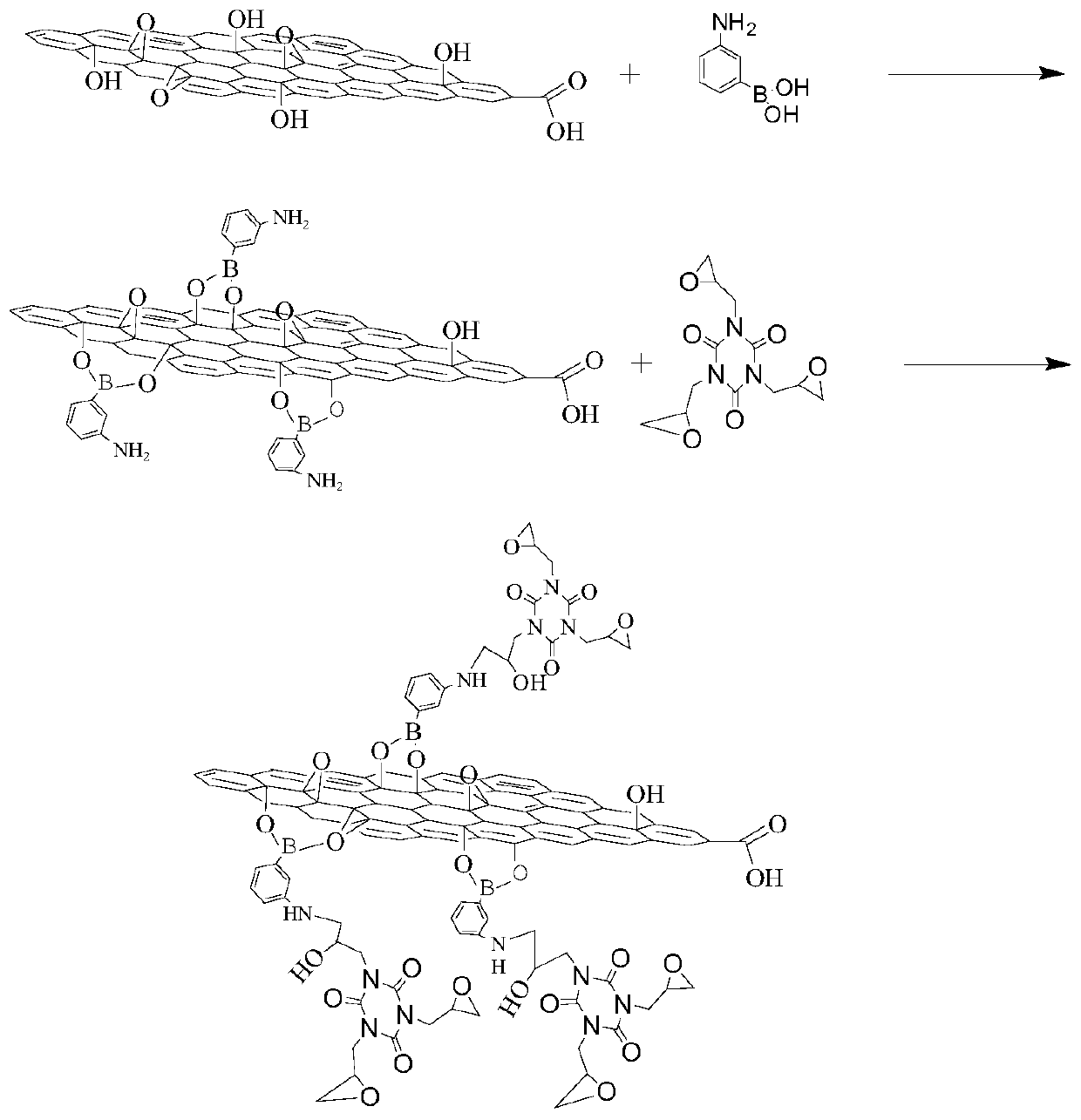

[0038] (1) Preparation of highly dispersed modified graphene oxide:

[0039] a) 0.2 g of graphene oxide and 0.2 g of 3-aminophenylboronic acid were ultrasonically dispersed in toluene, heated to 100° C. for reflux reaction for 6 hours, suction filtered and washed to obtain 3-aminophenylboronic acid-modified graphene oxide;

[0040] b) Take 0.1 g of 3-aminophenylboronic acid-modified graphene oxide obtained in step a) and 1 g of triglycidyl isocyanurate in 100 mL of N,N-dimethylformamide, heat to 150° C. for reflux reaction for 24 h, Filter and wash to obtain highly dispersed modified graphene oxide.

[0041] (2) Preparation of highly dispersed modified graphene oxide composite anti-corrosion coatings

[0042] Take 1g of highly dispersed modified graphene oxide prepared in step (1), 50g epoxy resin, 0.5g silicone, 0.2g defoamer BYK302, 0.5g dispersant BYK101, 0.5g ethylene glycol phenyl ether, 20g 1, 4-Butanediol diglycidyl ether is mixed, uniformly dispersed on a high-speed ...

Embodiment 2

[0044] (1) prepare highly dispersed modified graphene oxide;

[0045] With embodiment 1.

[0046] (2) Prepare highly dispersed modified graphene oxide composite anticorrosion coating;

[0047] The mass of highly dispersed modified graphene oxide in Example 1 was adjusted to 0.5g.

Embodiment 3

[0049] (1) prepare highly dispersed modified graphene oxide;

[0050] With embodiment 1.

[0051] (2) Prepare highly dispersed modified graphene oxide composite anticorrosion coating;

[0052] The mass of highly dispersed modified graphene oxide in Example 1 was adjusted to 1.5 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com