Block copolymer for adhesive, production method therefor, and adhesive composition

A technology of block copolymer and manufacturing method, which is applied in the direction of adhesives, etc., can solve the problems of insufficient balance of adhesive adhesive properties and insufficient improvement effect, etc., and achieve excellent solubility, good balance of properties, and excellent adhesion and bonding properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0275]With respect to 100 parts by mass of the block copolymer (polymer 1), 300 parts by mass of ARKON M100 (manufactured by Arakawa Chemical Industry Co., Ltd.) Co., Ltd.), and use a pressurized double-wrist kneader (model: D0.3-3, manufactured by Moriyama Manufacturing Co., Ltd.) to melt and knead at 180°C for 30 minutes to obtain light yellow Homogeneous hot melt adhesive adhesive composition.

[0276] It should be noted that in the adhesive adhesive composition, 1 part by mass of 2-tert-butyl-6-(3- tert-Butyl-2-hydroxy-5-methylbenzyl)-4-methylphenylacrylate.

[0277] According to the measurement method of the above-mentioned adhesive adhesive composition, the measurement results are as follows: the melt viscosity (at 180°C) is 920 (mPa·s), and the softening point is 89.8°C.

[0278] In addition, the applicability was good, and the ring tack was 53.4 N / 15 mm, the adhesive force was 30.7 N / 10 mm, and the holding power was 10.3 minutes, which was practically very good.

Embodiment 2~4

[0279] [Examples 2-4], [Comparative Examples 1-10]

[0280] According to the combination shown in the following Table 1 and Table 2, according to the same method as Example 1, using ARKON M100 as a tackifier, using Diana Process Oil PW-90 as a softener, respectively prepare adhesive adhesive compositions, evaluate its properties.

[0281] It should be noted that, when the kneading torque was not stabilized after 40 minutes, the kneading was continued until the torque became stable.

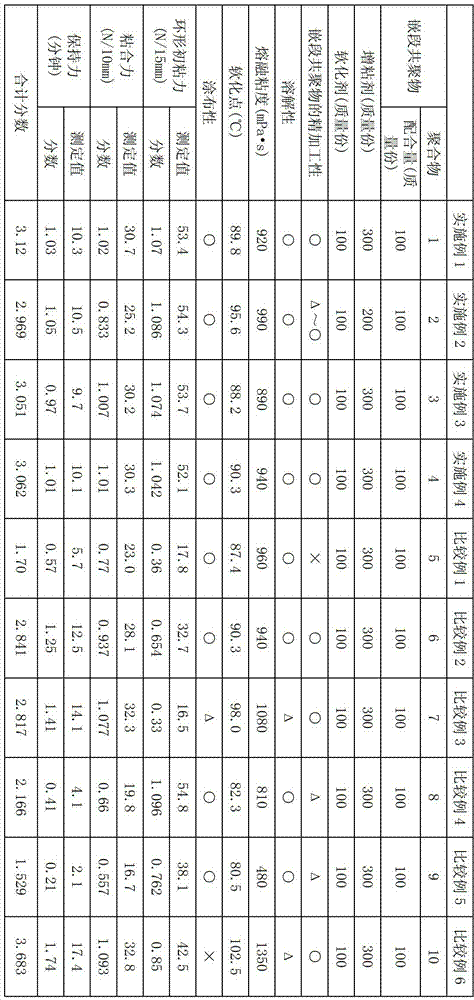

[0282] [Table 1]

[0283]

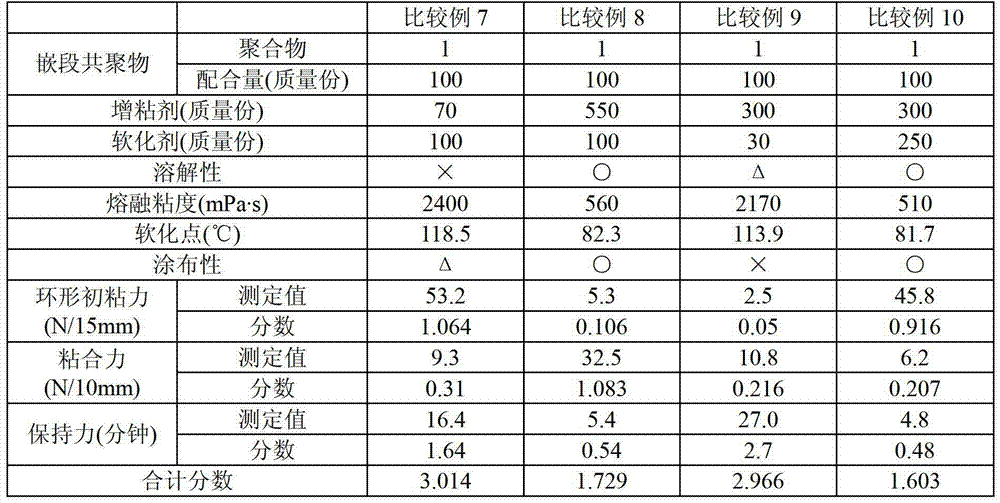

[0284] [Table 2]

[0285]

[0286] It can be seen that the block copolymers for pressure-sensitive adhesives (polymers 1 to 4) of Examples 1 to 4 all have practically good finishing properties.

[0287] In addition, it was found that any of the pressure-sensitive adhesive compositions of Examples 1 to 4 had good adhesive properties such as loop initial tack (adhesiveness), adhesive force, and holding power, and that these properties were well-balanced. Excelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Ring tack | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com