Automobile external covering part stamping die achieving lateral reshaping by using hydraulic system to drive sliding blocks

A technology for driving a sliding block and a hydraulic system, applied in the field of stamping dies, can solve the problems of inability to achieve negative angles, flanging, and the inability of stamping dies to remove workpieces, and achieve the effect of reducing production costs and stabilizing product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

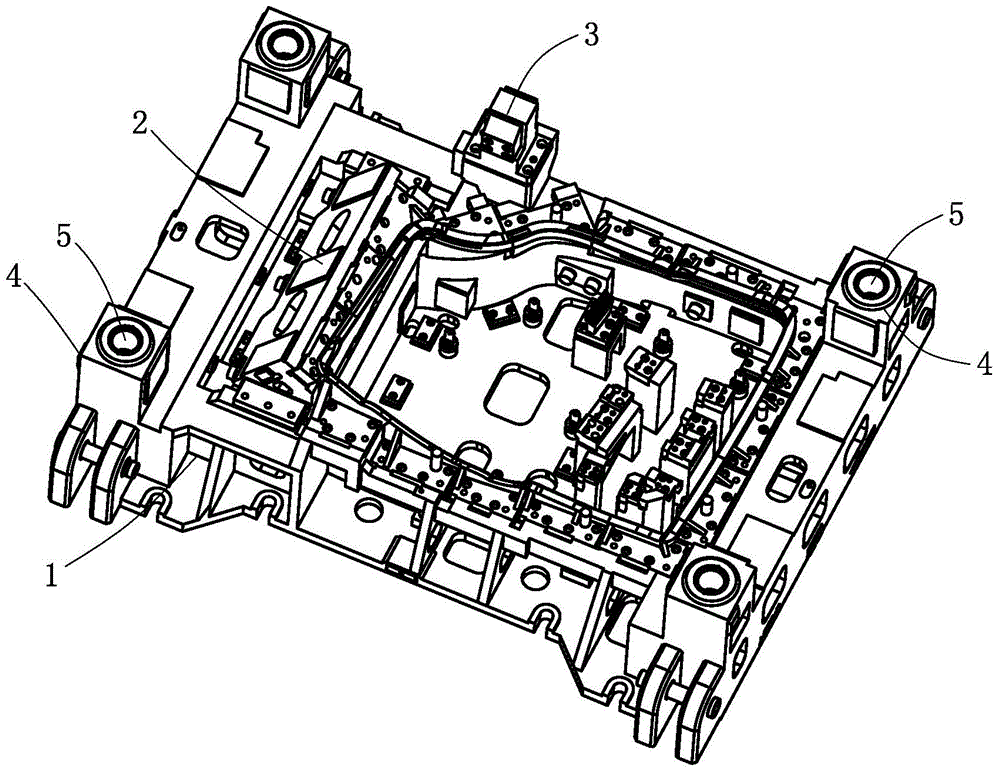

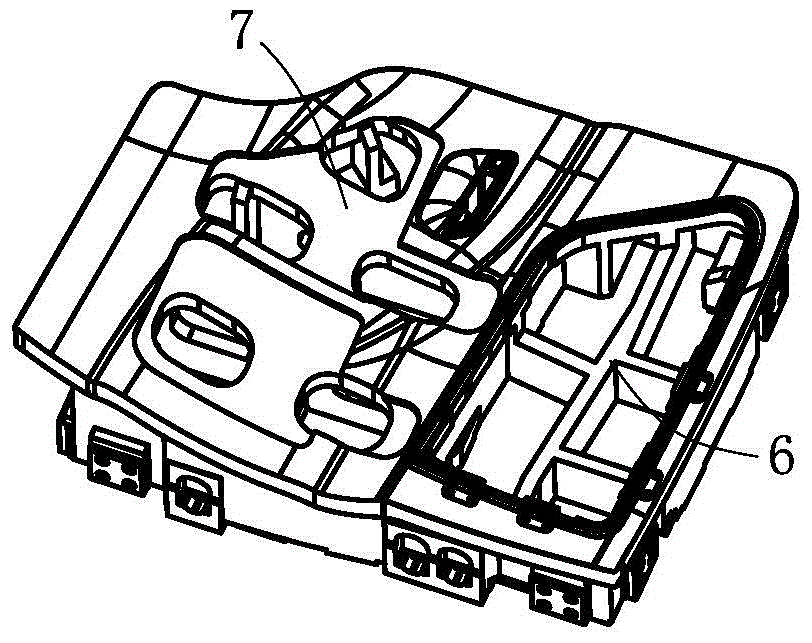

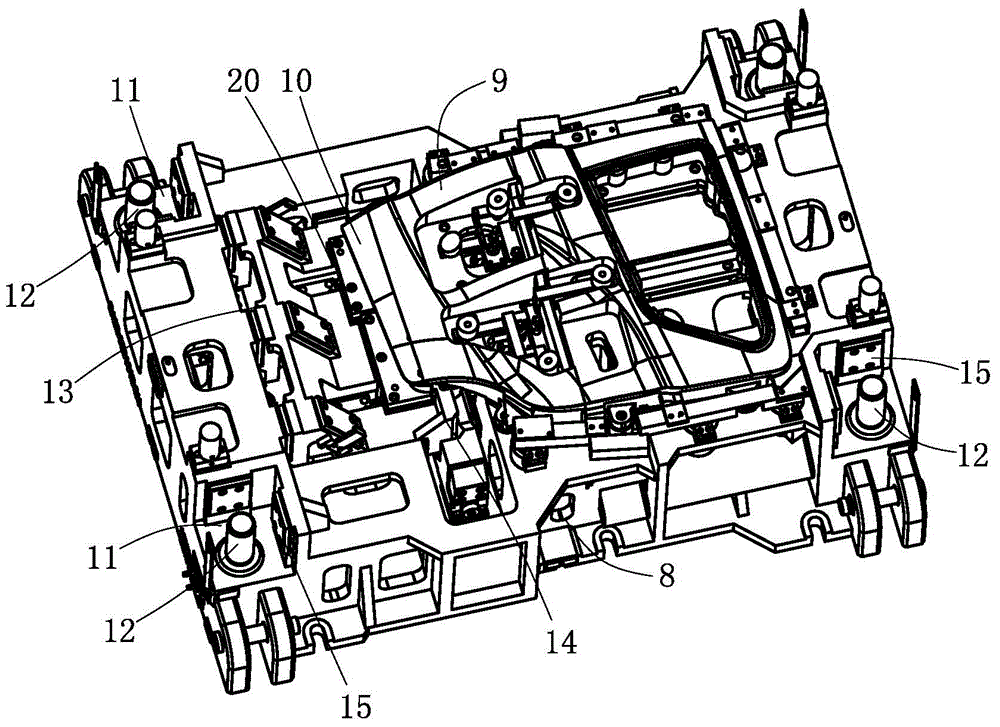

[0028] Such as Figure 1 to Figure 6 Commonly shown, the present invention provides a kind of stamping die of automobile outer cover part that realizes side trimming by driving slide block through hydraulic system, comprises upper mold body and lower mold body 8, and lower mold body 8 is provided with workpiece punch seat, and lower mold body A rotary mold body 20 is mounted on the mold body 8 through a hinge shaft 22, and one end of the rotary mold body 20 is connected to a hydraulic cylinder 21. Specifically, the piston rod of the hydraulic cylinder 21 is connected to the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com