Manufacturing surface finishing clamp for water pump impeller

A technology of surface finishing and water pump impeller, which is applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece supports, etc. It can solve the problems that the area cannot be polished and occupies part of the surface area of the impeller, and achieve the effect of reducing the area occupied by the fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

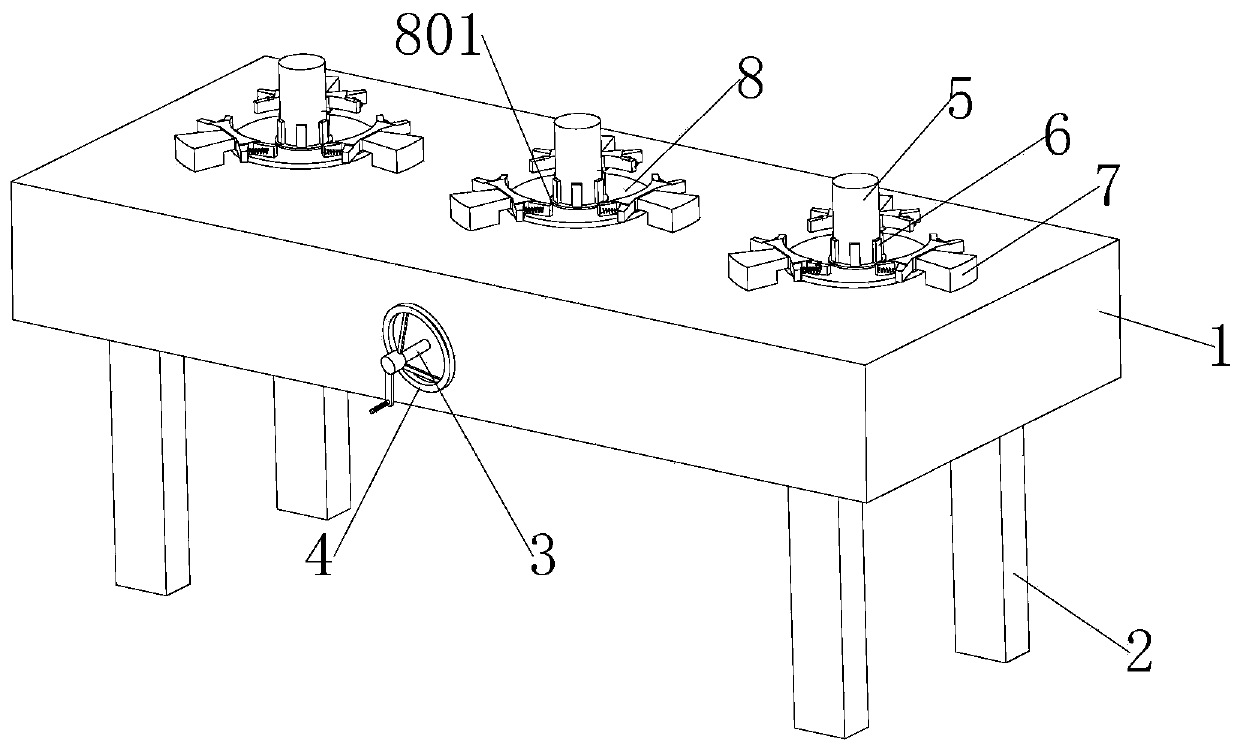

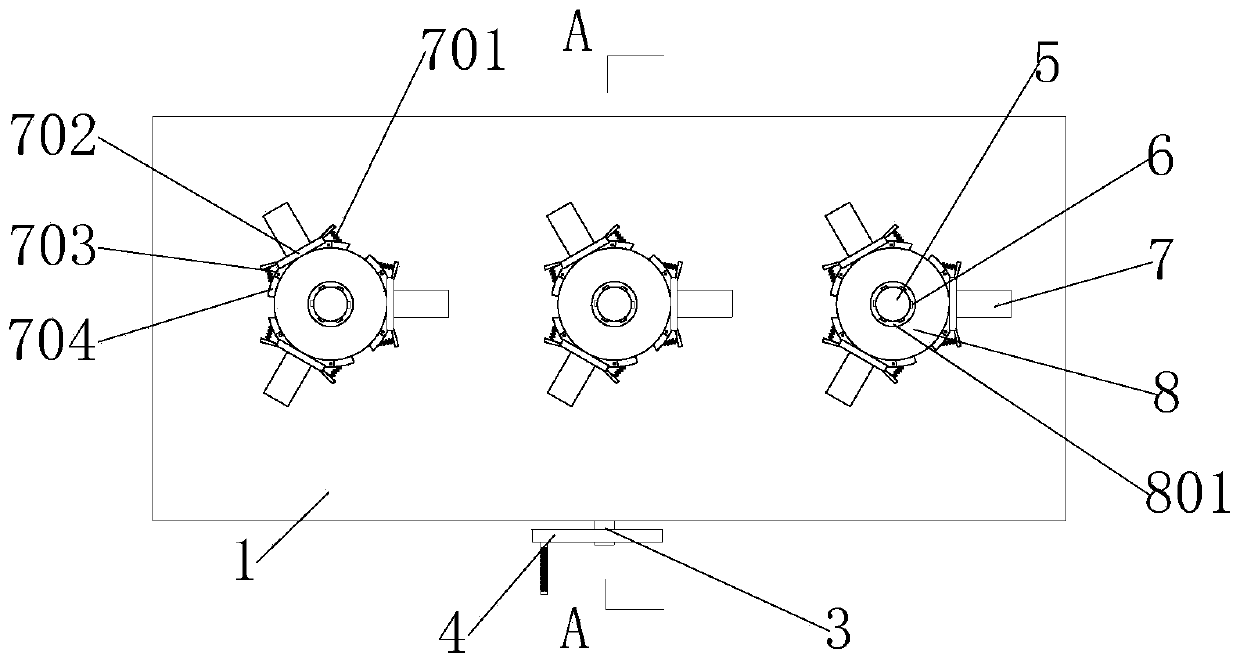

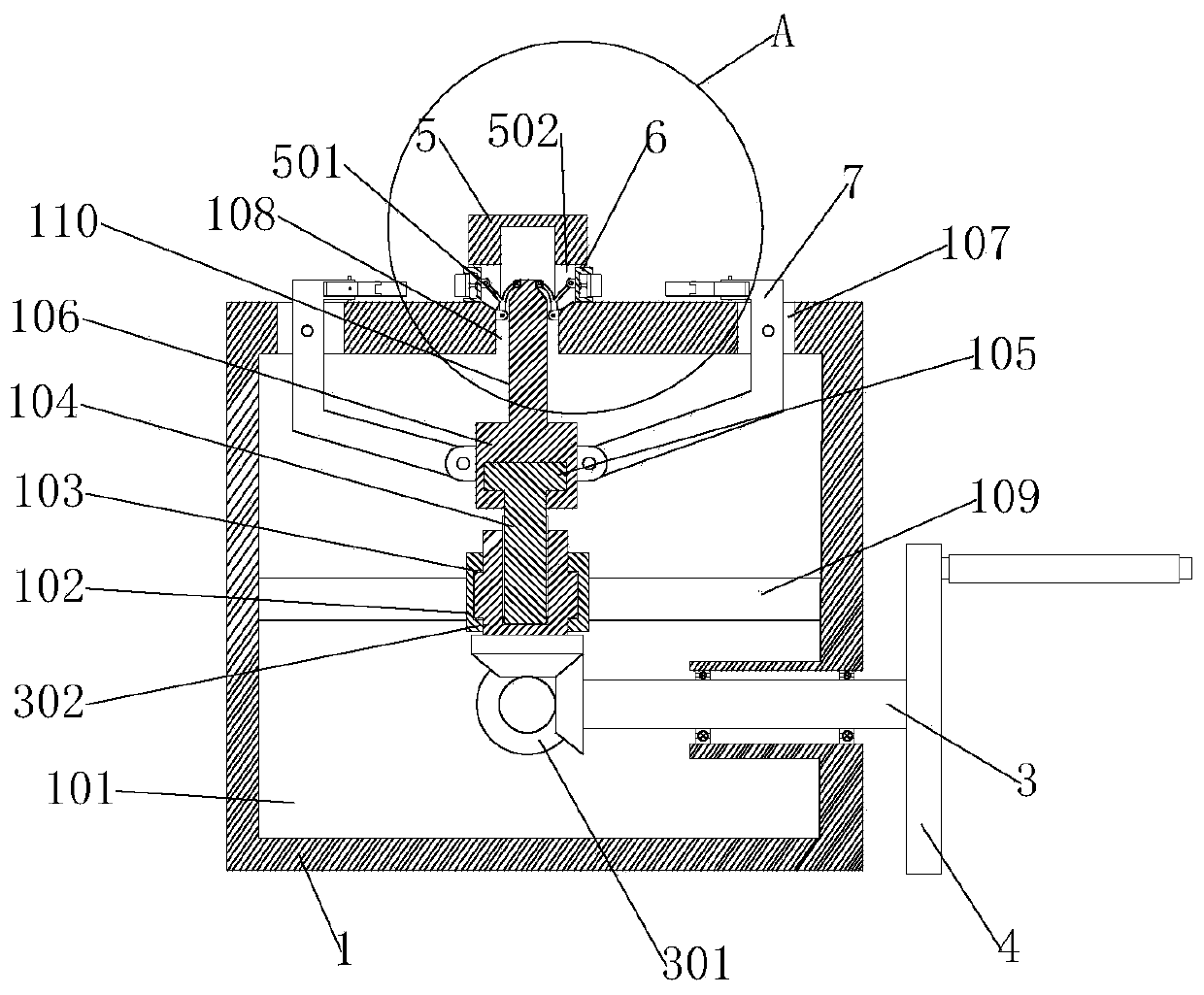

[0036] see Figure 1-6, is a schematic diagram of the overall structure of a jig for manufacturing surface finishing of a water pump impeller, a jig for manufacturing a surface finishing of a water pump impeller, including a workbench 1, the top of the workbench 1 is set as a horizontal table, and the bottom of the workbench 1 is close to four Each corner is provided with four supporting legs 2 supports, and the table top of workbench 1 is provided with a plurality of disc-shaped positioning platforms 8, and the top circle center position of positioning platform 8 is provided with disc-shaped positioning boss 801, and positioning boss 801 The top of the top is provided with a guide rod 5 upright on the table, the guide rod 5 is a cylindrical rod structure, the outer wall of the guide rod 5 is provided with a plurality of chute 502 near the top of the positioning boss 801, and the inner wall of the guide rod 5 is provided with a top The rod give way hole 108, the chute 502 comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com