Fish seafood processing device

A processing device and seafood technology, which is applied in fish processing, slicing fish, fish cleaning/descaling, etc. It can solve the problems of inability to process large deep-sea fish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

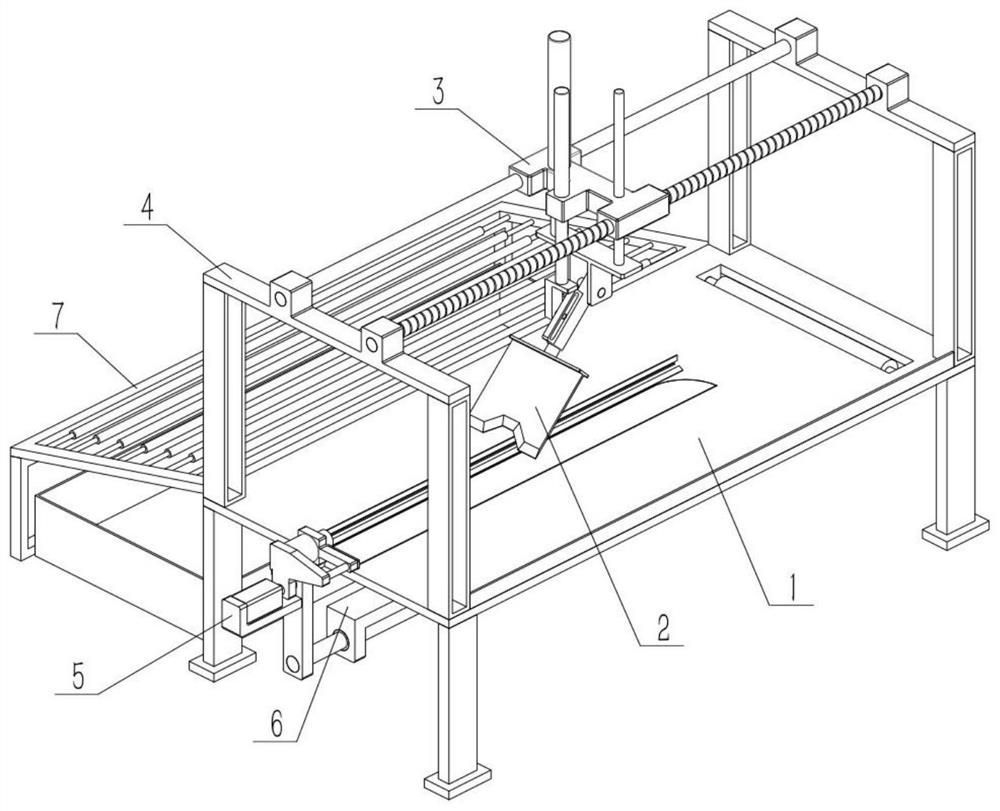

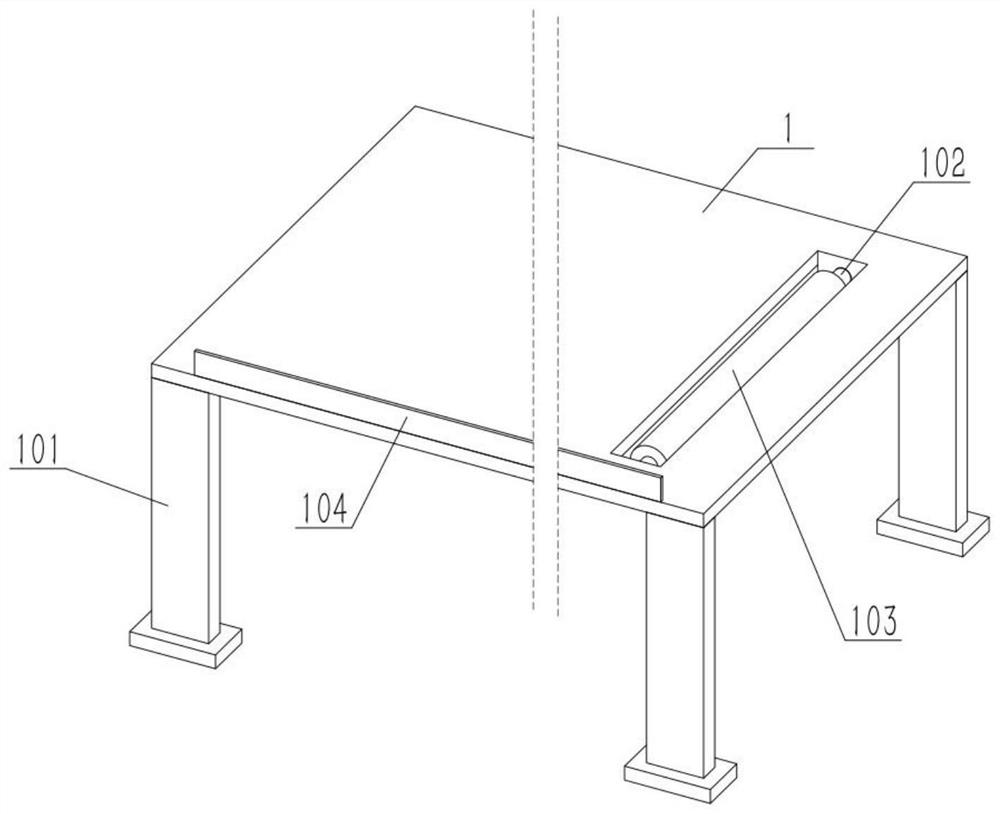

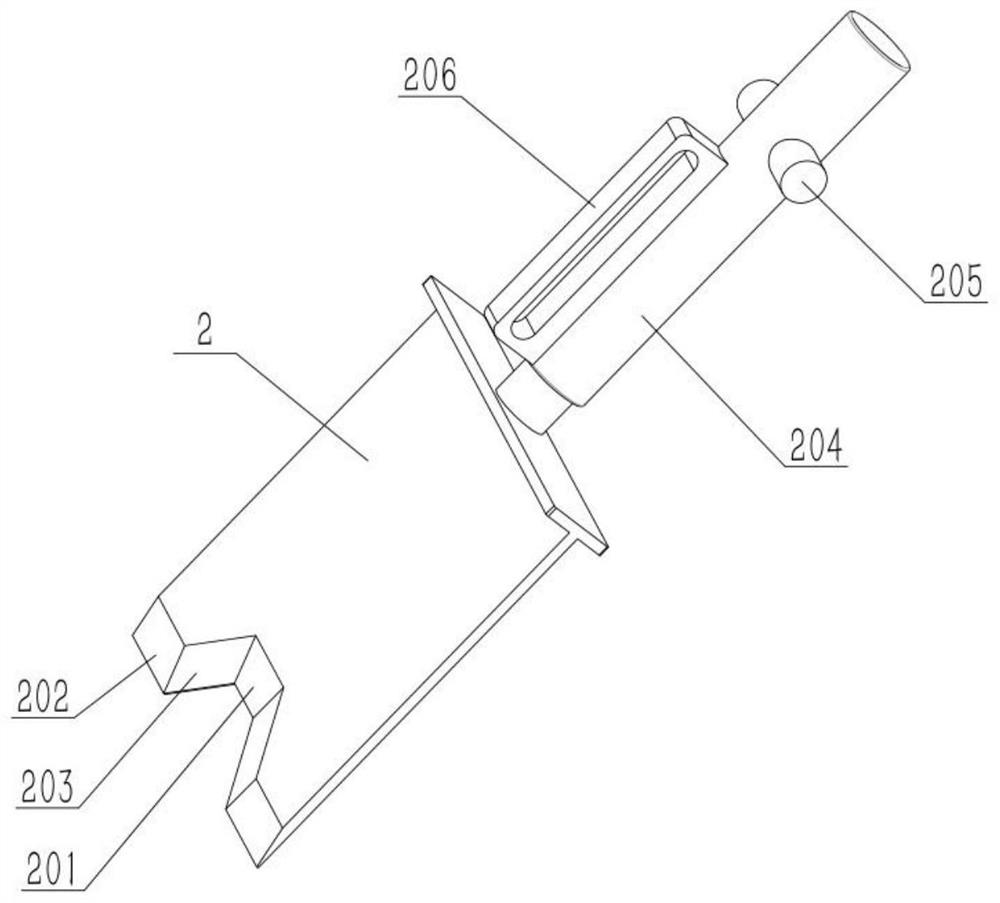

[0030] As shown in the figure, a fish and seafood processing device includes a processing table 1, a supporting foot I101, a plate knife 2, a concave cutting edge 201, a convex cutting edge 202, an inclined cutting edge 203 and an electric push rod I204. The four corners of the lower end of the table top 1 are all connected with a support foot I101, and the board knife 2 is set on the top of the processing table 1 with a low left and a right height, and the board knife 2 is fixed on the movable end of the electric push rod I204, which is used to adjust The position of the panel knife 2 along the inclination direction of the panel knife 2, the electric push rod I204 is installed on the adjustment mechanism, the concave cutting edge 201 is set in the middle of the left end of the panel knife 2, the front and rear ends of the inclined cutting edge 203 and the concave cutting edge 201 The outer ends of the two oblique cutting edges 203 are connected to one convex cutting edge 202 ....

specific Embodiment approach 2

[0032]As shown in the figure, the adjustment mechanism includes shaft II 205, seat with straight notch 206, upper base 3, electric push rod II 301, lower base 303, electric push rod III 304, L-shaped seat 305 and lever 306, the electric push rod The front and rear ends of the upper right side of the rod I204 are fixedly connected to a shaft II205, the upper end of the electric push rod I204 shell is fixedly connected to a straight notch seat 206, and the straight notch seat 206 is located on the left side of the shaft II205, and the upper end of the base 3 is fixed Connect the electric push rod II 301, the movable end of the electric push rod II 301 passes through the upper base 3 from top to bottom, the lower base 303 is fixedly connected to the movable end of the electric push rod II 301, and the two shafts II 205 are connected to the lower base 303 in rotation The lower side of the electric push rod III 304 is fixed on the upper end of the upper base 3, the movable end of th...

specific Embodiment approach 3

[0034] As shown in the figure, the fish and seafood processing device also includes a stabilizing rod 302 , which is slidably connected to the upper base 3 , and the lower end of the stabilizing rod 302 is fixedly connected to the upper end of the lower base 303 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com