Tea screening and drying finish processing device

A screening and drying technology, applied in the direction of drying gas arrangement, filtering, drying, etc., can solve the problems of inconvenient use and operation, poor finishing effect, damage, etc., and achieve simple and convenient use and operation, and good finishing effect , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

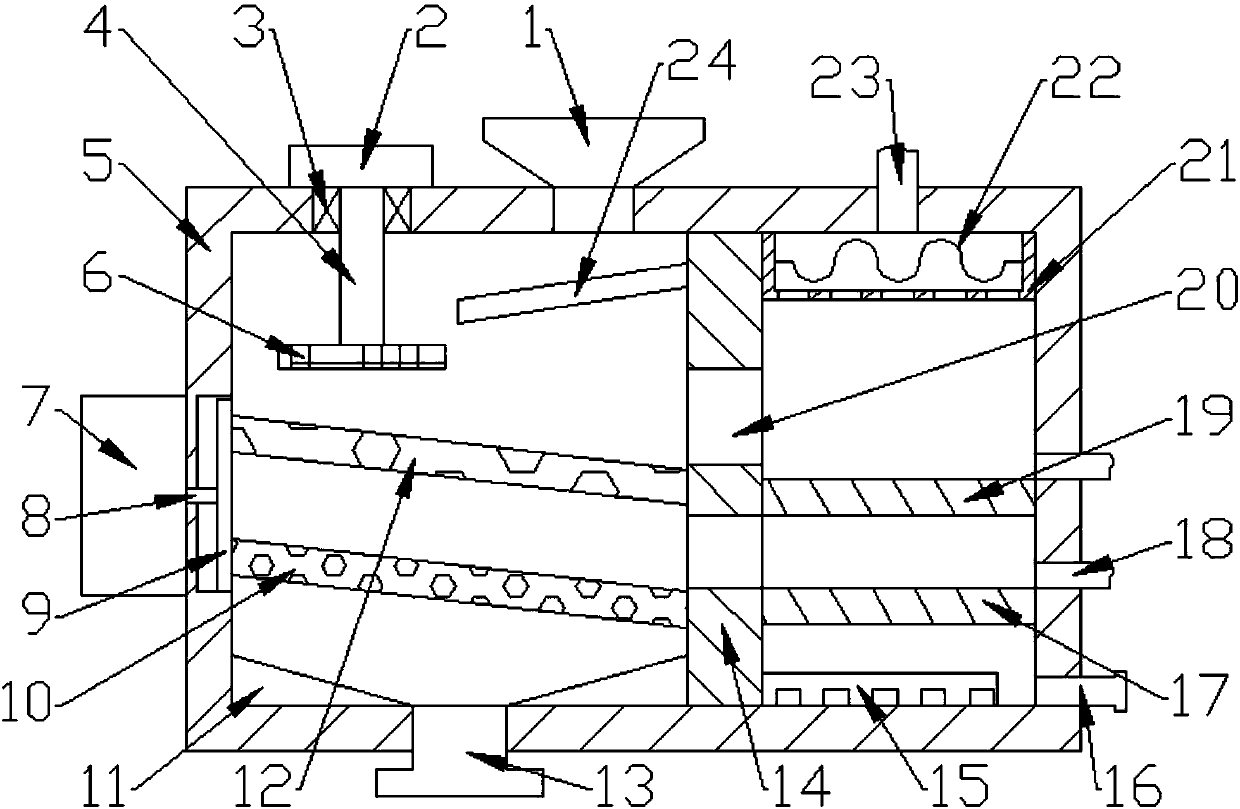

[0020] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

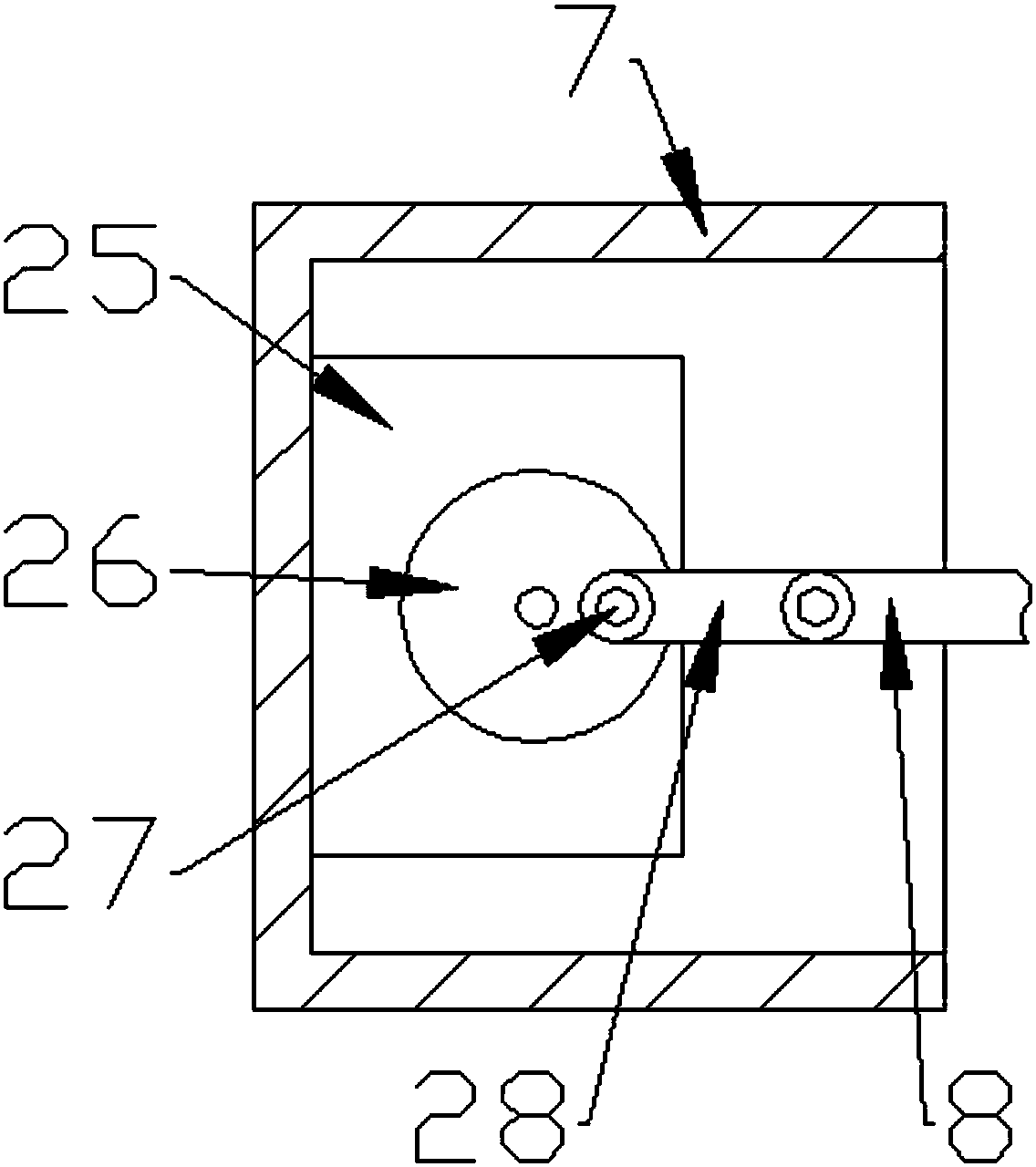

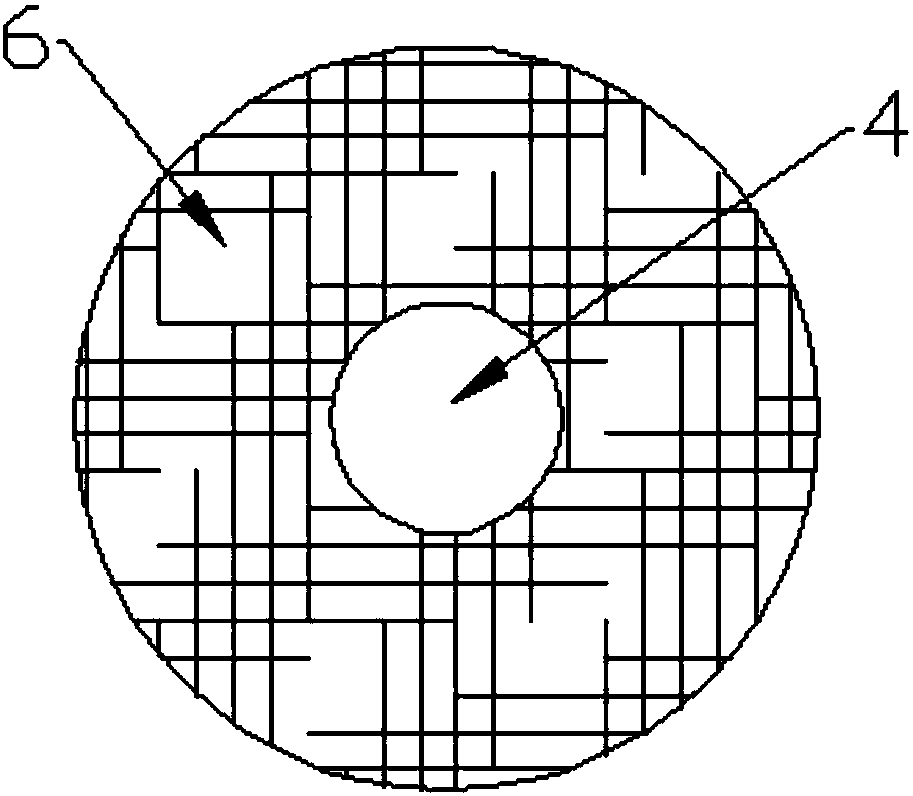

[0021] see Figure 1-4 , a kind of tea sieving and drying finishing device, comprising processing box 5; The middle part of the upper surface of said processing box 5 is welded and fixed feed inlet 1; Said feed inlet 1 inputs the tea leaves to be finished; A material guide plate 24 is provided below; the material guide plate 24 is arranged in the processing box 5, and is welded on the left side of the partition plate 14 with a low left side and a high right side, so as to provide guidance for the tea leaves falling from the feed port 1 The left side bottom of the material guide plate 24 is provided with a magnetic plate 6; the magnetic plate 6 is rotated from right to left, so that the tealeaves falling from the material guide plate 24 are rotated and dropped, and in this process, the tea leaves are removed by magnetic action. The metal impurity c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com