Paint-applying method for car body

A technology for automobiles and car bodies, applied in chemical instruments and methods, devices for coating liquids on surfaces, coatings, etc., can solve problems such as failure to achieve design, difficult safety management, and difficulty in recycling coating films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

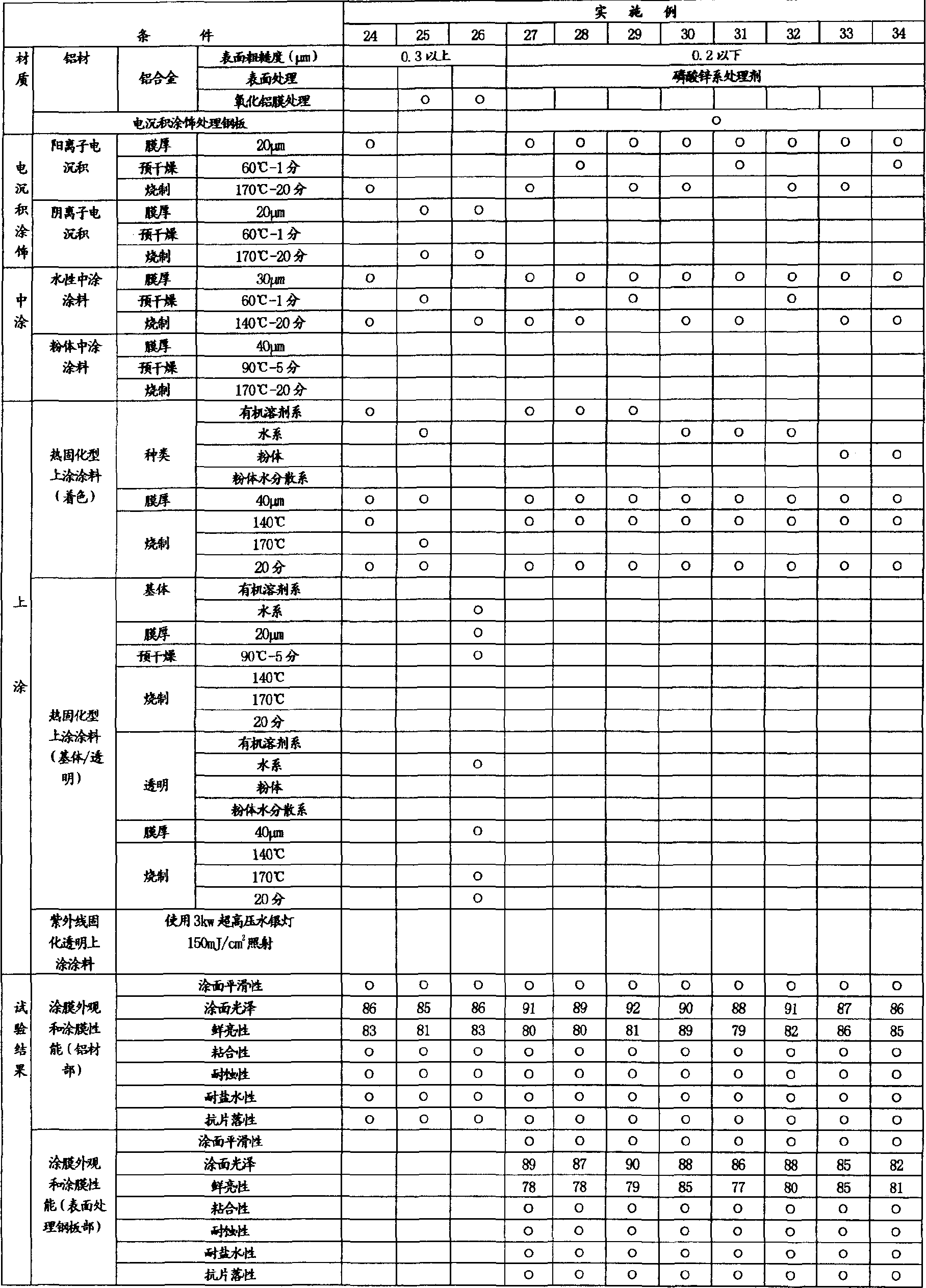

[0242] After degreasing and cleaning the 0.8mm thick aluminum plate (JIS A6061), the surface was treated with a zinc phosphate treatment agent, and then, the cationic electrodeposition coating ELECRON GT-10 (manufactured by Kansai Paint Co., Ltd., Blocked polyisocyanate curable epoxy resin electrodeposition paint), fired at 170°C for 20 minutes, to obtain an electrodeposition painted plate with a dry film thickness of about 20 μm. On the electrodeposition coated surface, the following thermosetting water-based intermediate coating was sprayed to form a 30 μm thick film, and fired at 140° C. for 20 minutes. Then, spray a heat-curing top coat (manufactured by Kansai Paint Co., Ltd., NEOAMILAC #6000 white, organic solvent system) to form a dry film with a thickness of about 30 μm, and dry it with a dryer at 140° C. for 20 minutes to obtain each test panel .

Embodiment 2~26

[0244] According to the method described in Tables 1 and 2, the painted boards of Examples 2-26 were produced.

Embodiment 27~38

[0246] After degreasing and cleaning the 0.8mm thick aluminum plate (JIS A6061), it is treated with a zinc phosphate treatment agent to obtain a surface-treated aluminum material, and the surface of the zinc-iron alloyed hot-dip galvanized steel sheet is treated with a zinc phosphate treatment agent. A surface-treated plate was obtained, and the following cationic electrodeposition paint was painted to a thickness of 20 μm. After washing with water, it was fired at 170° C. for 20 minutes to obtain a painted steel plate. The two plates are welded so that the painted surfaces of the aluminum material and the steel plate painted according to the following procedure are in the same direction, and then the two surfaces of the aluminum material and the steel plate are painted according to the finishing conditions recorded in Tables 1 and 2.

[0247] In Tables 1 and 2, the aluminum oxide film treatment was carried out as follows.

[0248] condition

[0249] cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com