Rotor self-circulation cooling system and cooling method for high-speed motor direct-drive turbomachinery

A technology of high-speed motors and turbomachinery, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of inconspicuous cooling effect, large cooling air volume, and large circulation resistance, etc., and achieve the overall appearance, coordination and comprehensiveness of the unit Low energy consumption and low cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

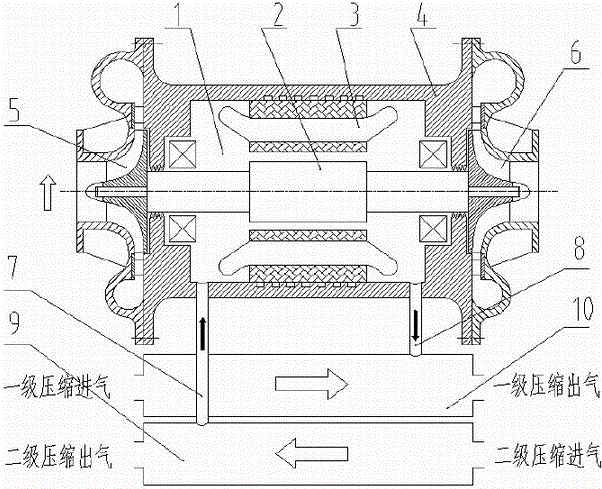

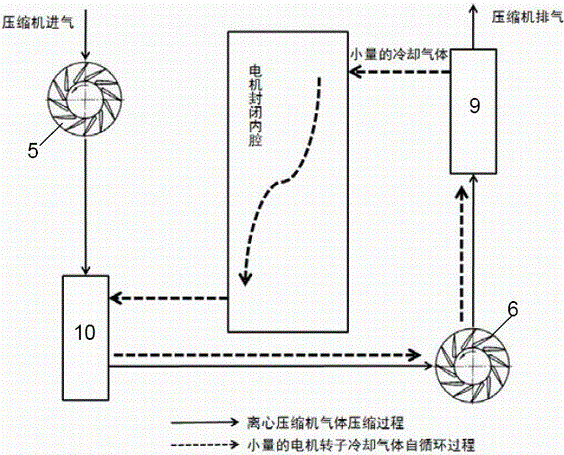

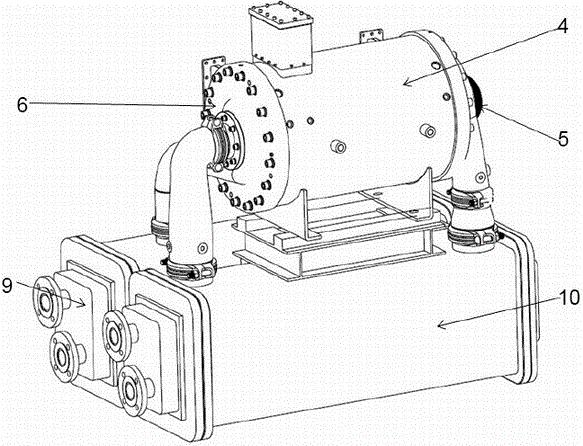

[0032] The rotor self-circulation cooling system and cooling method of the high-speed motor direct-drive turbomachinery of the present invention will be described in detail below with reference to the drawings and embodiments.

[0033] see figure 1 , the present invention provides a motor rotor self-circulation cooling system of a high-speed motor direct-drive centrifugal compressor, which is mainly composed of a motor closed casing 4, a high-speed motor inner cavity 1, a high-speed motor rotor 2, a motor stator coil 3, and a first-stage compressor 5 , secondary compression 6, rotor cavity cooling intake pipe 7, rotor cavity cooling outlet pipe 8, compressor primary cooler 10 and compressor secondary cooler 9.

[0034] The high-speed motor rotor 2 is arranged in the middle of the motor closed housing 4, and bearing seats and bearings are installed between the motor rotor 2 sides and the motor closed housing 4 inner walls. A motor stator coil 3 is installed on the periphery of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com