Closed water cooling system with double-evaporative cooling pressure

A technology for evaporative cooling and cooling systems, applied in steam/steam condensers, fixed conduit components, heat exchanger types, etc., can solve problems such as increased infrastructure investment, high temperature of closed water, increased water consumption of air-cooled thermal power units, etc. , to achieve the effect of reducing investment, lowering evaporation temperature and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Now take a closed water cooling system with a closed water flow rate of 2000t / h, a closed water temperature drop of 7K, from 45°C to 38°C, and double evaporative cooling pressure as an example to illustrate the optimal way to realize the invention:

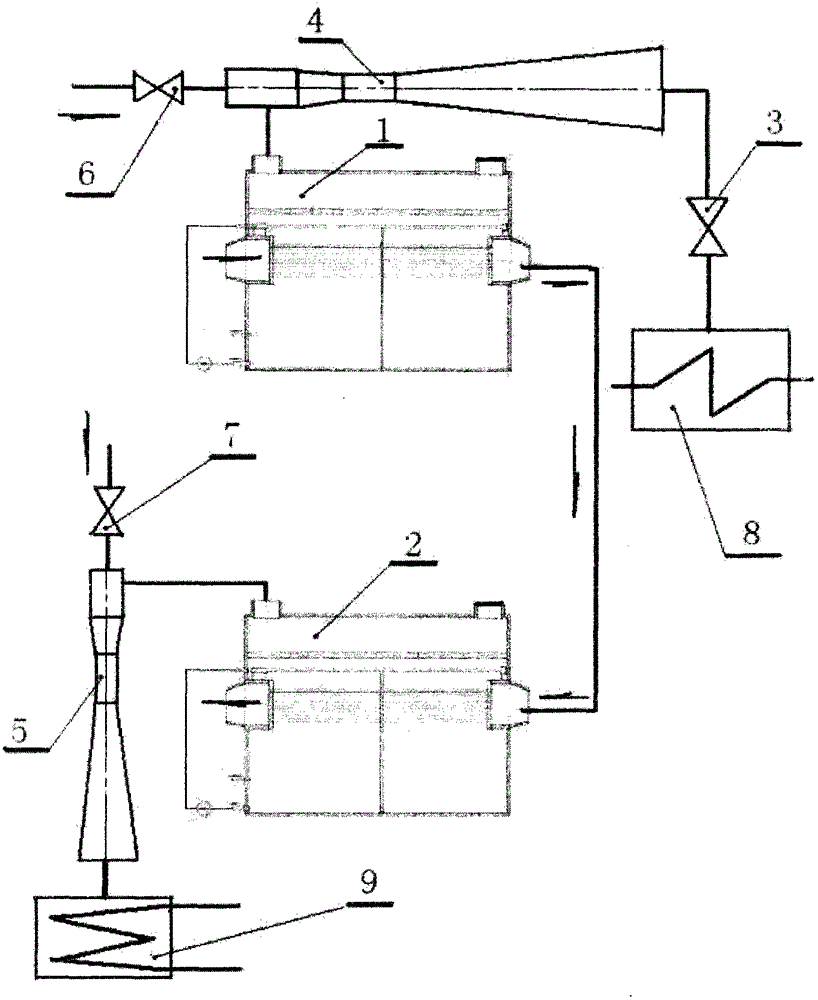

[0039] The closed water cooling system with double evaporative cooling pressure of the present invention comprises a once-through evaporative cooling closed water cooler A (1), a once-through evaporative cooling closed water cooler B (2), a vacuum butterfly valve (3), and a steam ejector A(4), steam ejector B(5), 5-stage extraction steam inlet regulating valve (6), plant auxiliary steam inlet steam regulating valve (7), No. 8 low-pressure heater (8), condenser ( 9), liquid level sensor and DCS control system; the vacuum state of 0.005MPa (a) required on the shell side of once-through evaporative cooling closed water cooler A (1) is realized by steam ejector A (4); steam ejector A The nozzle of (4) is supplied by the 5-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com