Heat-pipe module heat dissipation oil bath electromotor

A motor and heat dissipation technology, applied in the field of motors, can solve problems such as insufficient capacity, and achieve the effect of solving cooling problems, ensuring normal operation, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

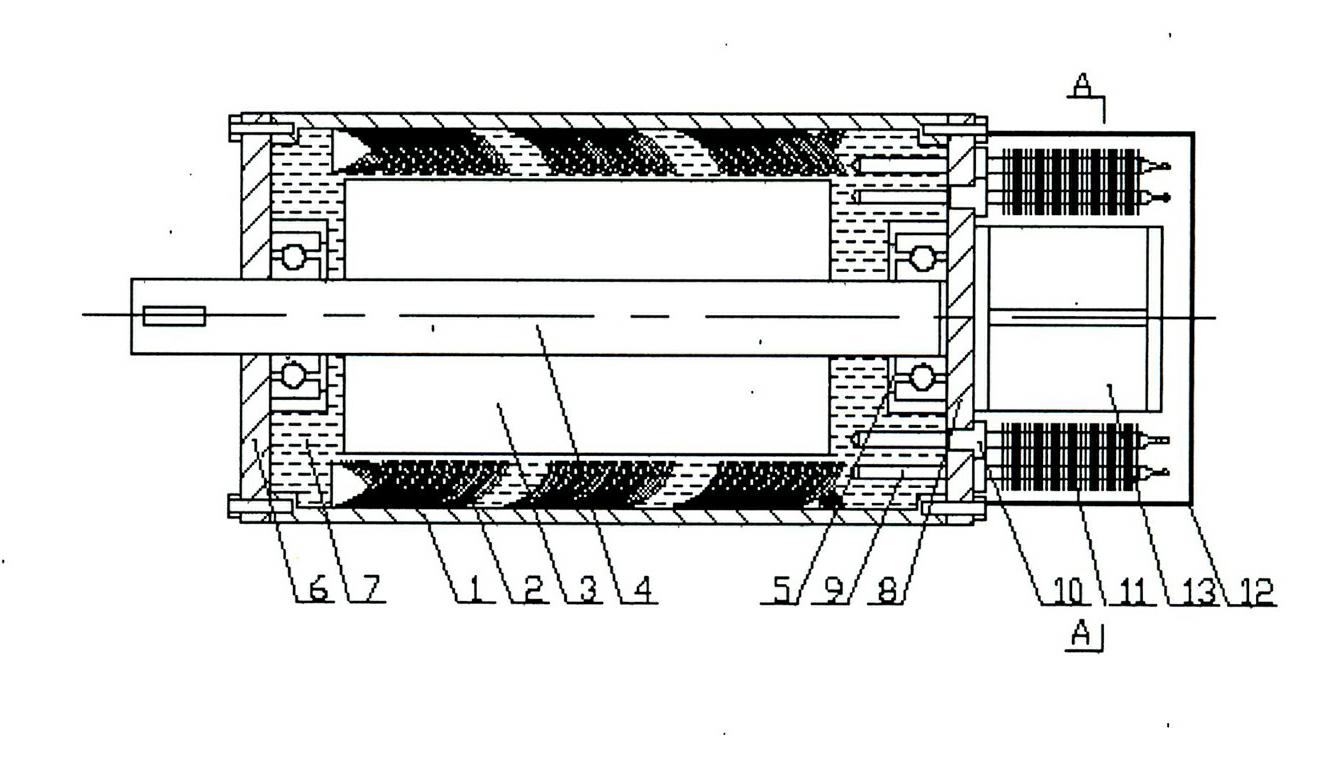

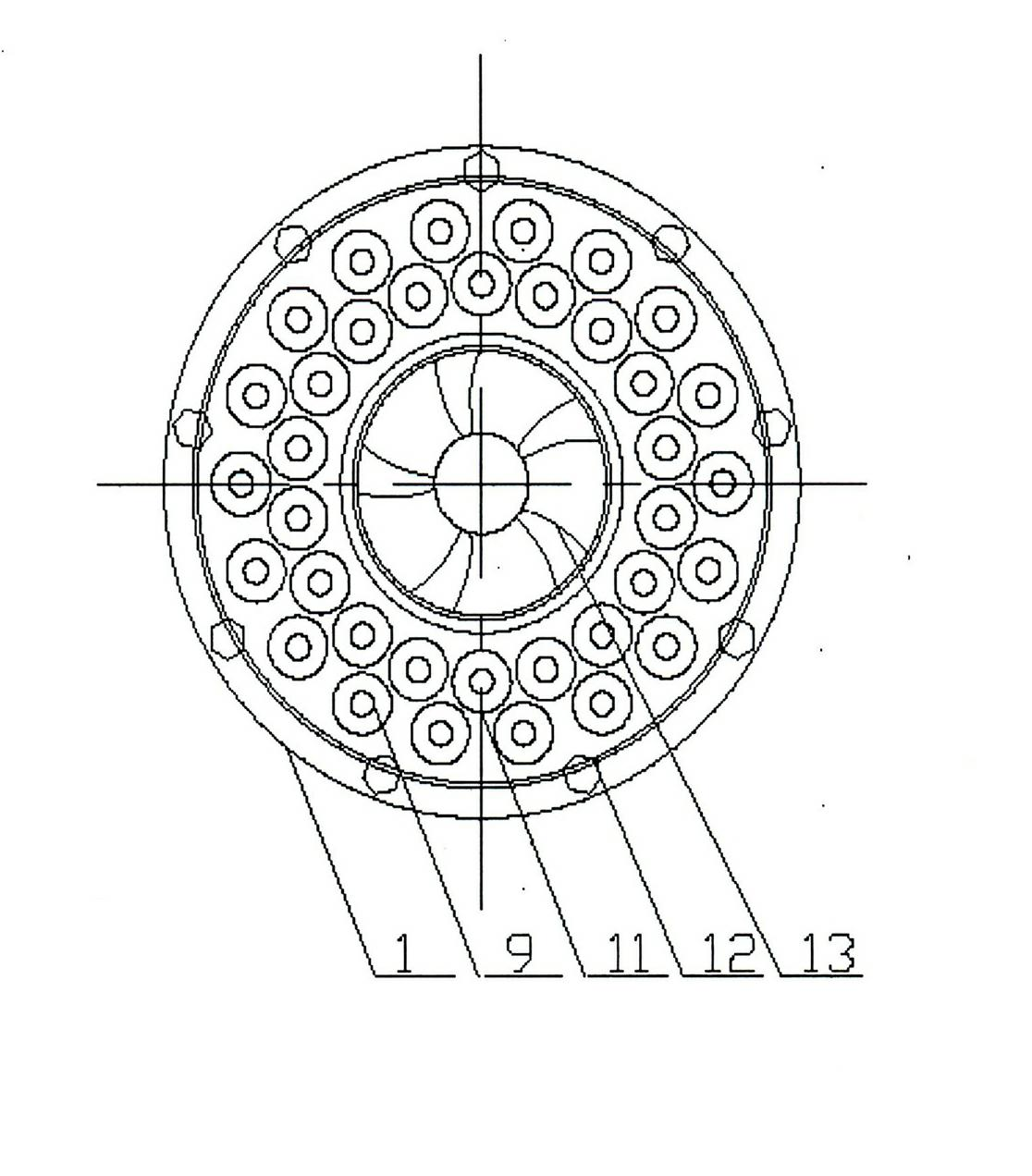

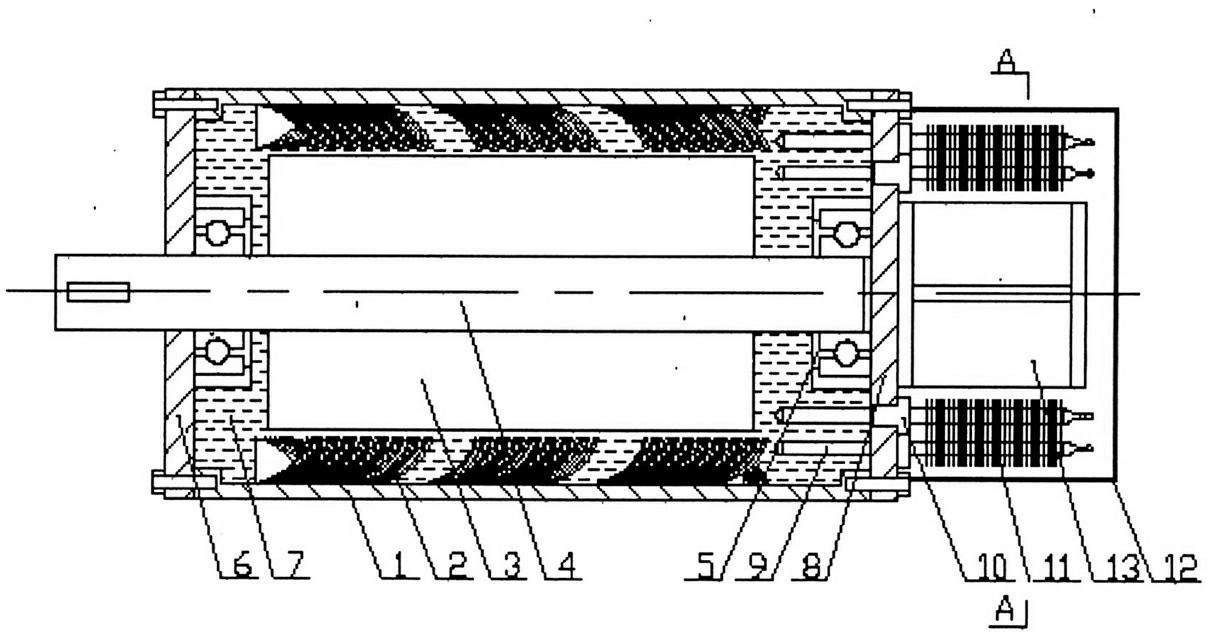

[0011] exist figure 1 In the schematic diagram of the front view section of the heat pipe module heat dissipation oil bath motor shown, the motor stator 2 is arranged in the closed casing 1 of the motor, and the motor rotor 3 corresponding to it is arranged on the motor shaft 4, and the motor shaft wears Through two supporting bearings 5 and an end plate 6 of the housing, it stretches out of the housing. The motor housing between the stator, rotor, shaft and support bearings is filled with cooling oil 7 . The end plate of the housing without the motor shaft passing through is a hole plate 8, and a heat pipe 9 is arranged in each through hole, and the middle part of the heat pipe is fixed and sealed on the end plate by a fixing flange 10. The above-mentioned heat pipe with internal heat transfer working medium has a heat absorbing section located inside the casing, and a heat dissipation section located outside the casing, and fins 11 are arranged on the outside. A protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com