Multifunctional mechanical sealing axle sleeve

A multi-functional mechanical and mechanical sealing technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of wasting raw materials, endangering personal and equipment safety, pollution, etc., to prolong the service life and shorten the cantilever ratio. , the effect of protecting the environment and personal equipment safety

Inactive Publication Date: 2009-01-07

王加华

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this way, the external working pressure of the seal is always proportional to the outlet pressure of the pump. For positive pressure, leakage is always inevitable, and often causes waste of raw materials and environmental pollution. In severe cases, it will endanger the safety of people and equipment. It is a pump product. The biggest and technical difficulties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] specific implementation plan

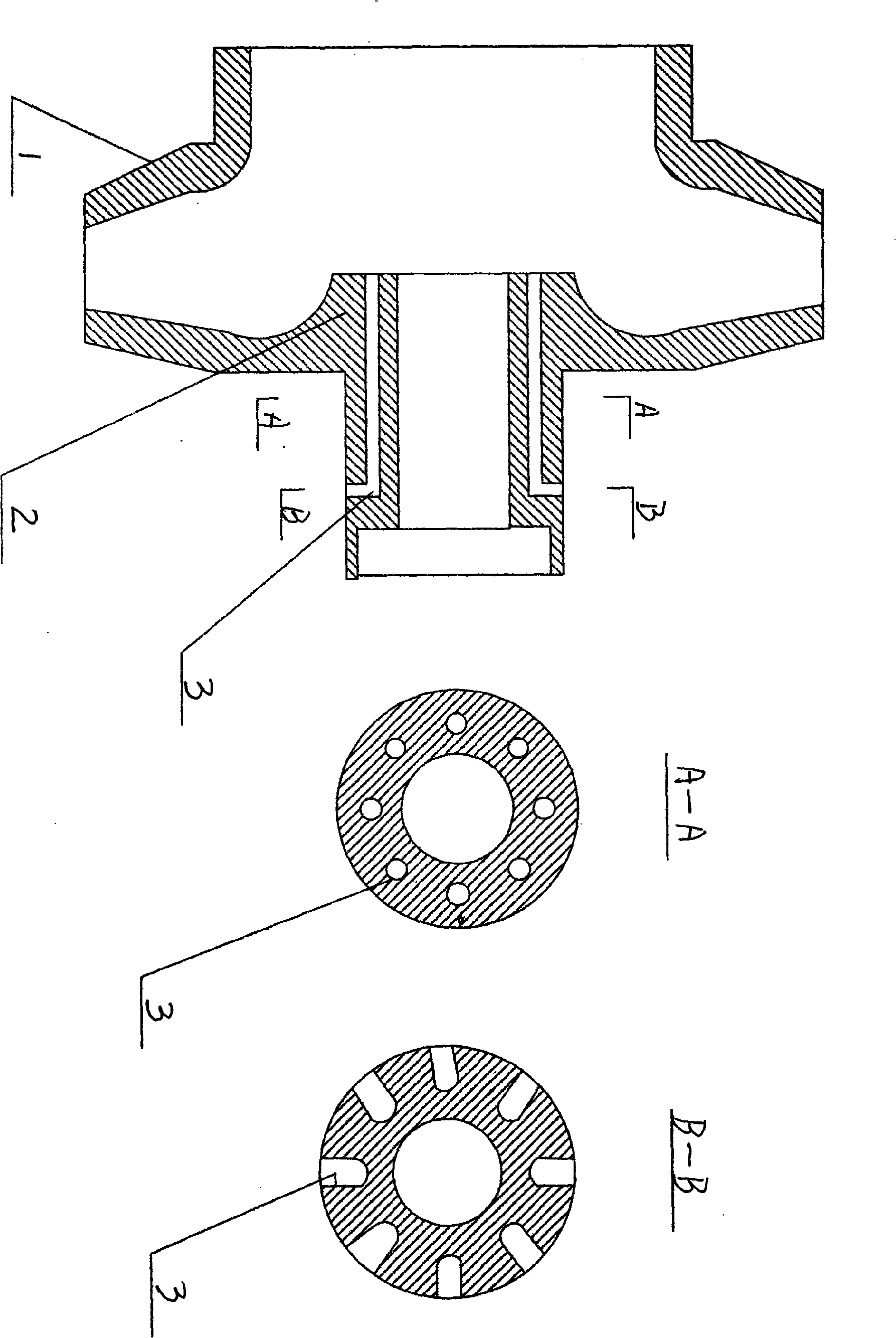

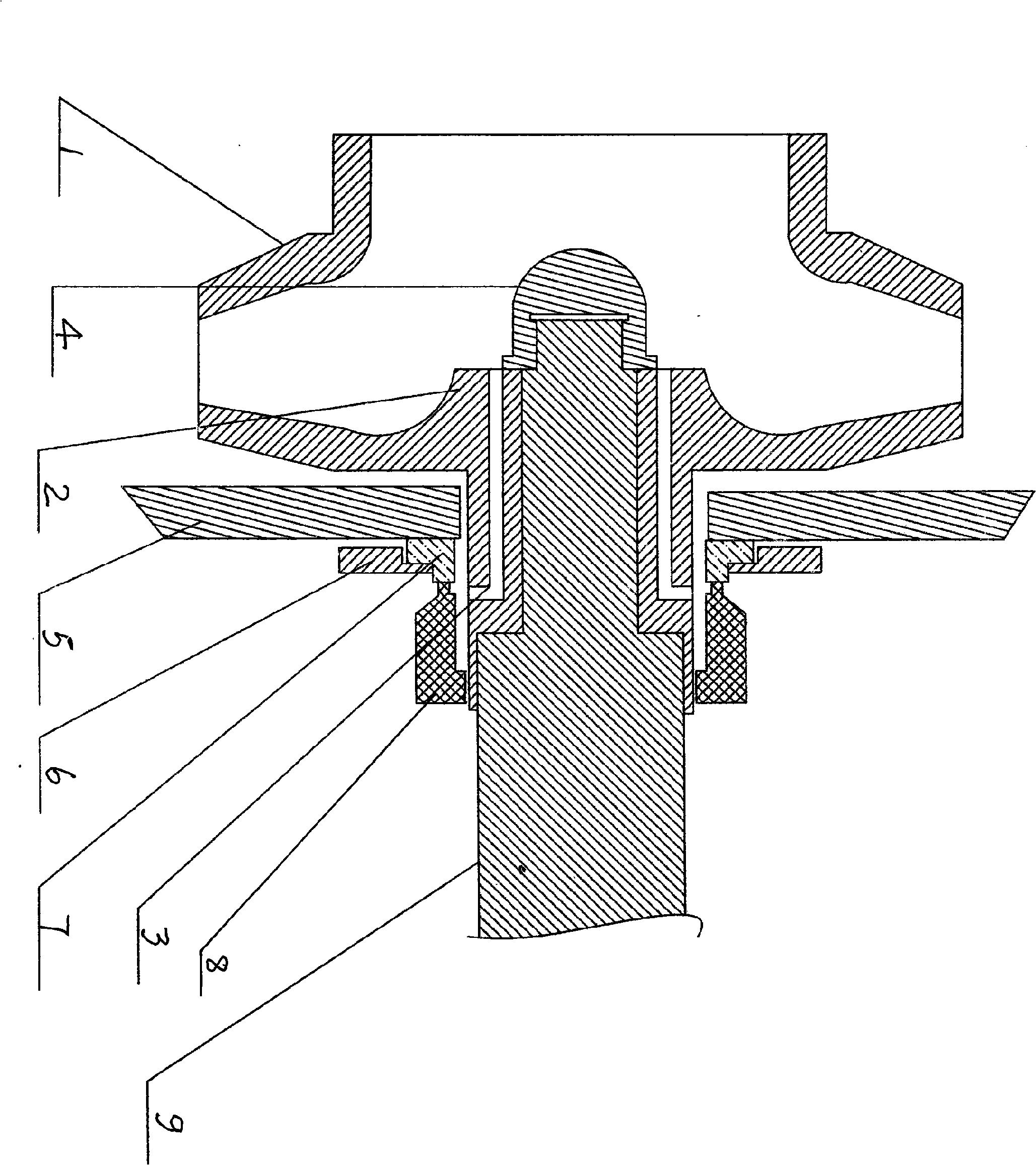

[0011] In the figure, the mechanical seal static ring (7) is installed outside the pump body (5), the mechanical seal dynamic ring assembly (8) is installed on the shaft sleeve (2), and the shaft sleeve (2) and the impeller are installed on the pump shaft (9), the pump shaft nut (4) fastens the impeller (1) and the shaft sleeve (2) on the pump shaft (9).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a multi-functional mechanical sealing shaft sleeve. A totally enclosed rotating porous internal cooling flow channel which is processed in the shaft sleeve is integrated with a vane wheel and communicated with the negative pressure area of a pump and the internal joint between a mechanical sealing moving ring and a mechanical sealing static ring. When the pump operates, working medium flows from the internal joint between the mechanical sealing moving ring and the mechanical sealing static ring to the negative pressure area of the pump for cooling, bringing away impurities in the sealing inner circle and effectively preventing the medium from leaking out at the same time. Thereby, the multi-functional mechanical sealing shaft sleeve not only resolves the problem of the cooling problem of an external mounted mechanical pump seal but also prevents the toxic medium in the pump and flammable and explosive gas from leaking out, and moreover, an external cooling device is not needed.

Description

Technical field [0001] The invention relates to the cooling and leakage technology of mechanical seals for pumps. This technology solves the cooling and leakage problems of the pump mechanical seal. It can effectively solve the leakage of toxic media and flammable and explosive gases in pump products. Background technique [0002] At present, the known mechanical seal shaft sleeves can only protect the pump shaft and slow down corrosion. The cooling of the mechanical seal can only be done by peripheral devices. In this way, the external working pressure of the seal is always proportional to the outlet pressure of the pump. For positive pressure, leakage is always inevitable, and often causes waste of raw materials and environmental pollution. In severe cases, it will endanger the safety of people and equipment. It is a pump product. The biggest problem and technical difficulty. Contents of the invention [0003] In order to overcome the above-mentioned technical diffic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04D29/10

Inventor 王加华

Owner 王加华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com