Cooling method and cooling device of end pump laser

A technology of cooling device and cooling method, which is applied in the field of end-pumped laser cooling, cooling device and laser source to achieve compact structure and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

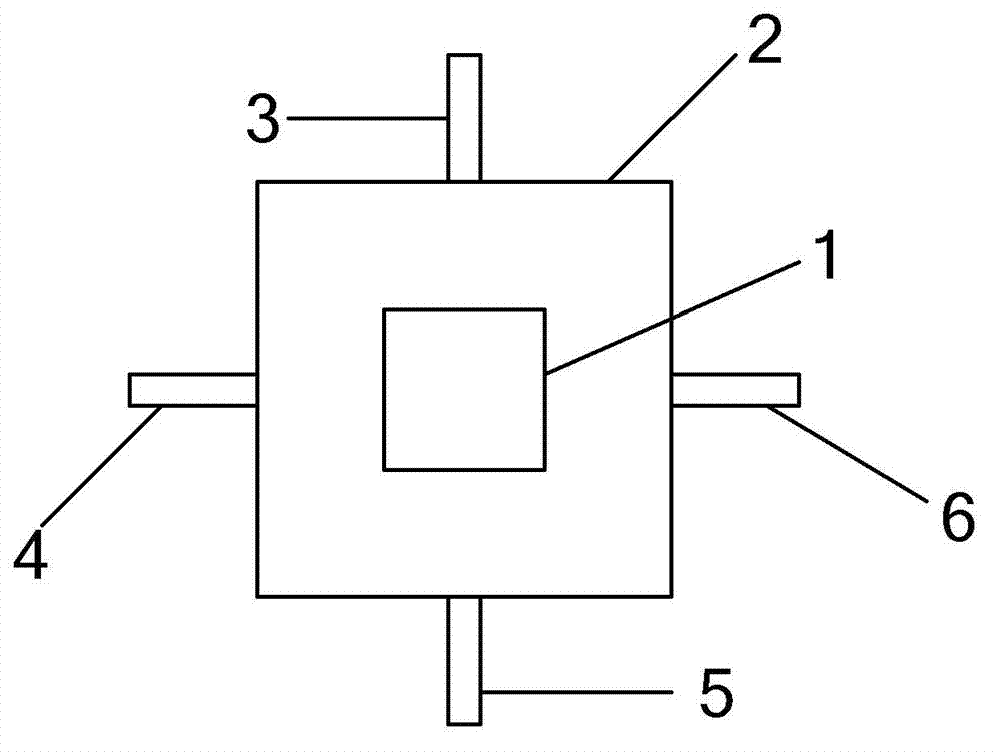

[0039] Embodiment 1 adopts end-pump pumping mode, as attached figure 1 2 is a square laser cavity that covers the crystal, and the pump light is focused inside the crystal after being focused. Laser crystals are placed in the cavity, of which 1 is a square laser crystal rod; in the vertical direction to the laser crystal rod, N slits are evenly opened on the laser cavity, and N rows of spray devices are arranged, of which 3, 4 , 5, 6 are 4 rows of spraying devices, wherein N=4; each row of spraying devices is provided with a spraying device every L1, wherein L1=11mm; the shortest distance between the spraying device and the laser crystal rod is L2, wherein L2=4mm; the flow rate of each spray device is P1, wherein P1=3.5mL / min; the diameter of the small water droplets produced by the spray is controlled at R2, wherein R2=110 μm; In the direction, there is an air inlet and an air outlet, and the blowing flow rate is P2, where P2=1.2L / min; the bottom of the cavity of the laser c...

Embodiment 2

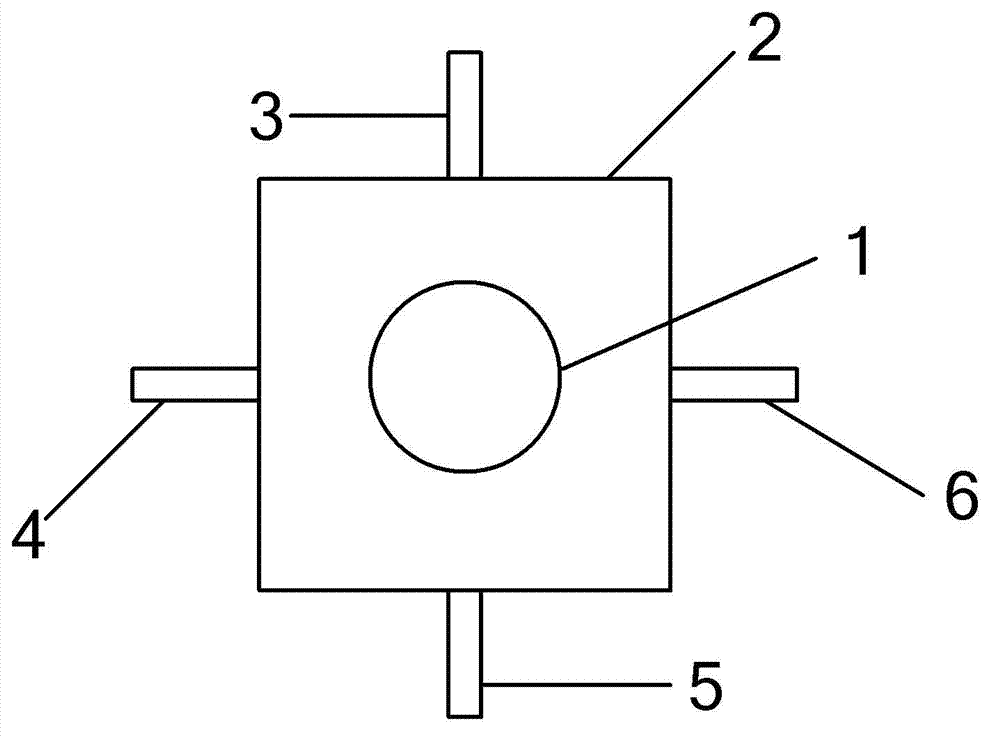

[0041] Embodiment 2 adopts end-pump pumping mode, as attached figure 2 2 is a square laser cavity that covers the crystal, and the pump light is focused inside the crystal after being focused. A laser crystal is placed in the cavity, 1 of which is a circular laser crystal; in the vertical direction to the laser crystal rod, N slits are evenly opened on the laser cavity, and N rows of spray devices are arranged, of which 3, 4 , 5, 6 are 4 rows of spraying devices, wherein N=4; each row of spraying devices is provided with a spraying device every L1, wherein L1=10mm; the shortest distance between the spraying device and the laser crystal rod is L2, wherein L2=4.5mm; The flow rate of each spray device is P1, wherein P1=3mL / min; the diameter of the small water droplets produced by the spray is controlled at R2, wherein R2=100 μm; In the direction, there is an air inlet and an air outlet, and the blowing flow rate is P2, where P2=1.35L / min; the bottom of the cavity of the laser c...

Embodiment 3

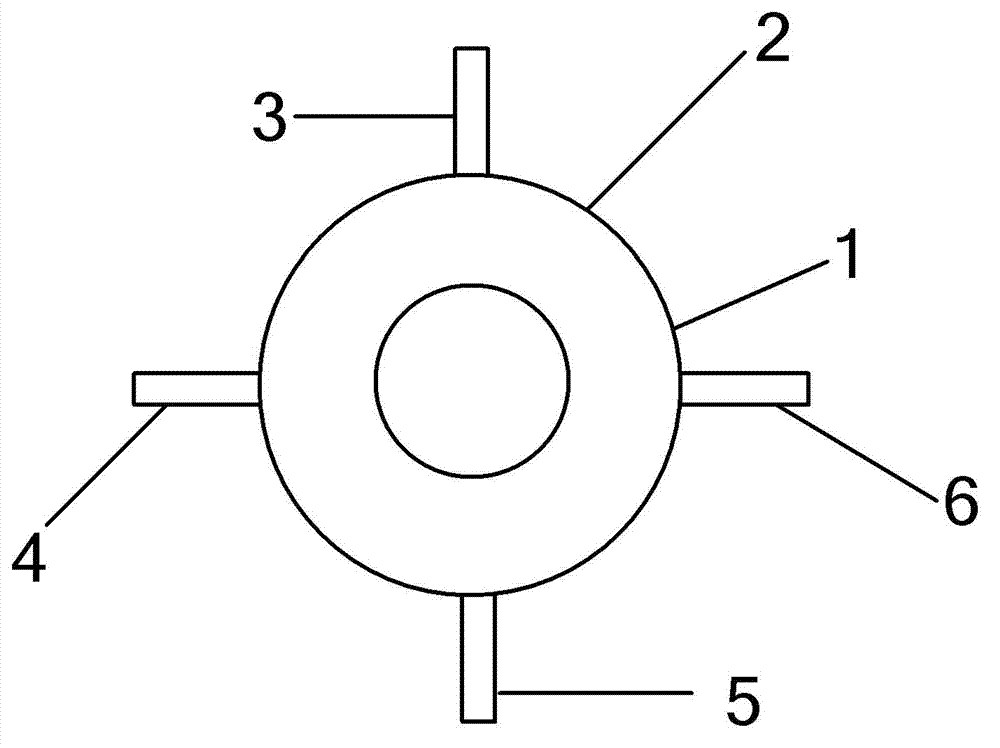

[0043] Embodiment 3 adopts end-pump pumping mode, as attached image 3 2 is a circular laser cavity covering the crystal, and the pump light is focused inside the crystal after being focused. A laser crystal is placed in the cavity, 1 of which is a circular laser crystal; in the vertical direction to the laser crystal rod, N slits are evenly opened on the laser cavity, and N rows of spray devices are arranged, of which 3, 4 , 5, 6 are 4 rows of spraying devices, wherein N=4; each row of spraying devices is provided with a spraying device every L1, wherein L1=10.5mm; the shortest distance between the spraying device and the laser crystal rod is L2, Wherein L2=3.5mm; The flow rate of each spray device is P1, wherein P1=3mL / min; the diameter of the small water droplets produced by the spray is controlled at R2, wherein R2=90 μm; parallel to the laser crystal rod In the direction of the air inlet and outlet, the blowing flow rate is P2, where P2 = 1.2L / min; the bottom of the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com