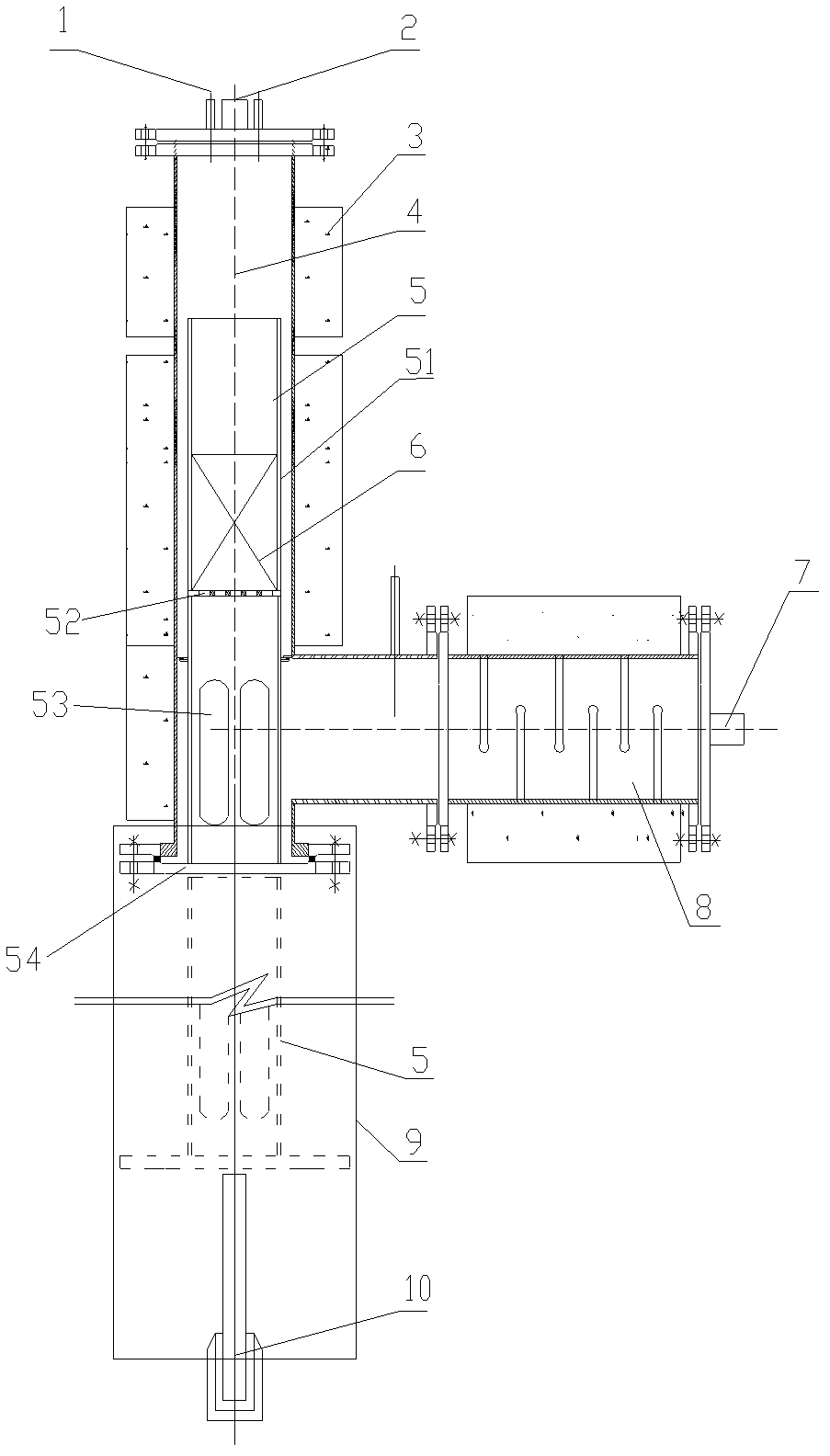

Reactor for semi-continuous production of carbon nano tube

A carbon nanotube and reactor technology, which is applied in the field of semi-continuous production of carbon nanotube reactors, can solve the problems of difficulty in realizing mass production of carbon nanotubes, long process cycle of intermittent fluidized bed, difficult process control, etc. The effect of large fluctuation, convenient entry and exit, and stable thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A certain amount of raw material is placed in the sagger 5, and the sagger 5 enters the reactor body 4 from the bottom (using a cracking furnace). Inert protective gas is introduced from the raw material gas inlet 9 to check the airtightness of the device. After the inspection is qualified, the heating electric furnace in the heating layer 3 is turned on to heat the reactor, and an inert gas is introduced for protection at the same time. When the temperature rises to the activation temperature of the catalyst, the reducing gas is introduced from the feed gas inlet 9 to ensure that the flow ratio of the inert gas and the reducing gas is constant. After the activation is complete, stop feeding the inert gas and reducing gas, and feed the raw gas CH from the raw gas inlet 9 4 , after being preheated by the gas preheater 8, the feed gas enters the carbon nanotube growth bed 6 for catalytic cracking reaction, CH 4 Catalytic cracking produces carbon nanotubes deposited on me...

Embodiment 2

[0028] A certain amount of catalyst is put into the sagger 5 of the reactor, and the sagger is installed into the reactor body 4 .

[0029] Set the program temperature controller so that the heating temperature of the cracking furnace is 650°C, the preheating temperature is 450°C, and the protective gas N 2 , catalyst reducing gas H 2 , feed gas CH 4 The flow ratio is about 12:2:1.

[0030] After reacting for 4h, stop feeding CH 4 , at N 2 Under the protection, the product is cooled in the first stage of the reactor, when the temperature of the reactor is reduced to 400 ° C, under N 2 The protection descends and moves the sagger 5 into the cooler 9 for cooling.

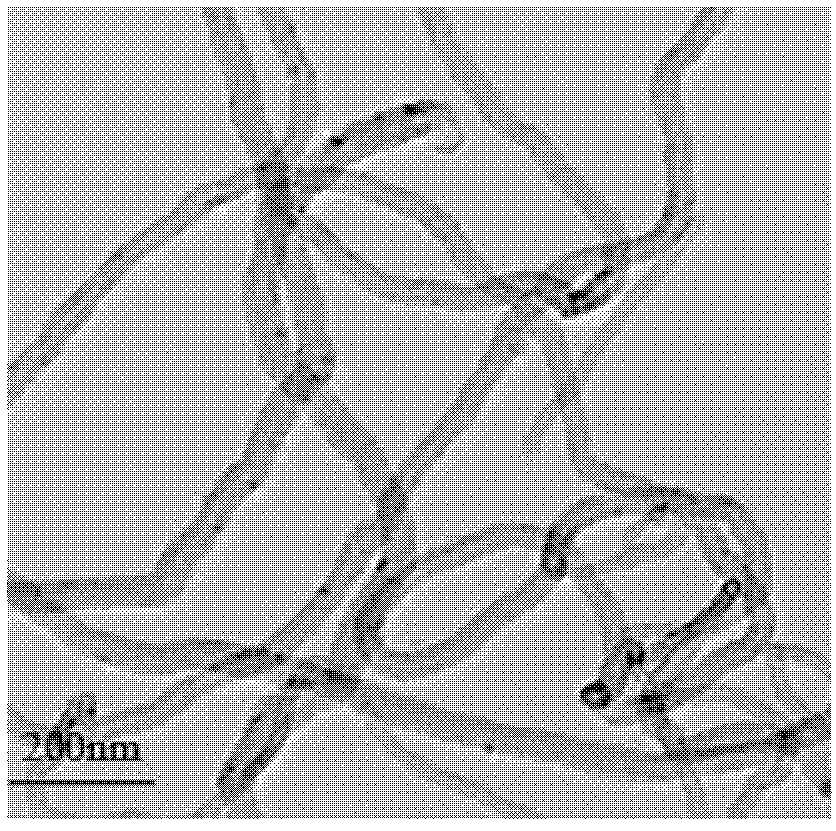

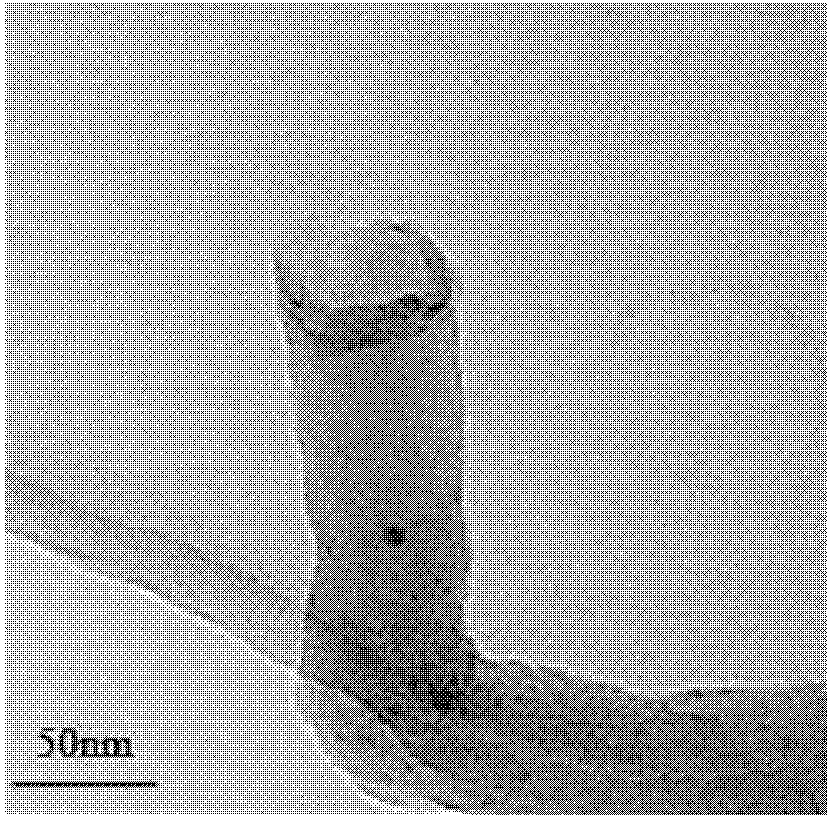

[0031] When the product temperature was cooled to room temperature, the product was taken out and weighed to obtain a carbon nanotube yield of 177.5g h -1 , by JEM-2100 (HR) transmission electron microscope (TEM) photos (see figure 2 with 3 ), it was observed that the outer diameter of carbon nanotubes was be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com