Fan for ultrahigh-temperature flue gas treatment

A flue gas treatment and ultra-high temperature technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve difficult working temperatures, unguaranteed maintenance cycles, production and maintenance costs. The problem of high cycle time is achieved, and the cooling effect is good, the structure is simple, and the high temperature flue gas leakage and the high temperature spindle cooling effect are solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and specific embodiments.

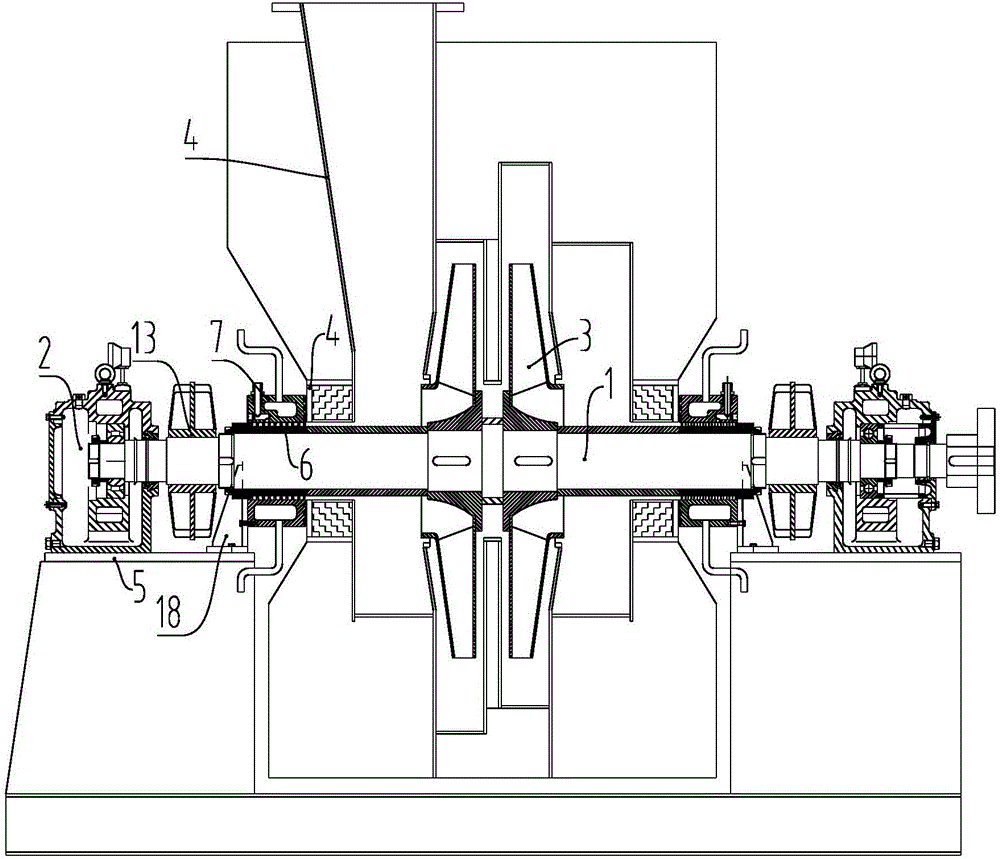

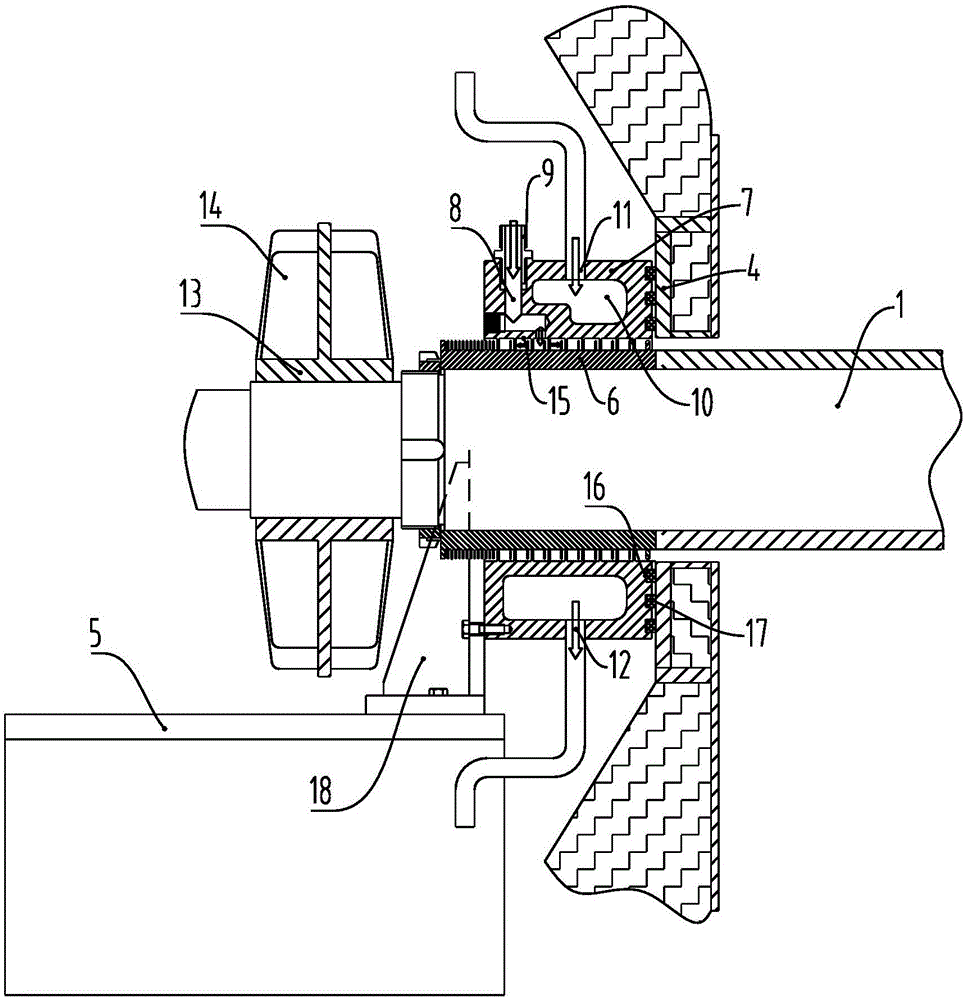

[0019] Such as figure 1 As shown, the fan used for ultra-high temperature flue gas treatment in this embodiment includes a main shaft 1, a bearing box 2 arranged on both ends of the main shaft 1, an impeller 3 and a casing 4 arranged on the main shaft 1, and the bearing boxes 2 are respectively arranged on On the base 5, a set of sealed cooling components are provided on the main shaft 1 on both sides of the casing 4. The sealed cooling components include a sealing component and a cooling component arranged on the fan main shaft 1, and the sealing component includes a sealing sleeve and The sealing sleeve 6, the sealing sleeve 6 is arranged on the main shaft 1, and the sealing sleeve and the sealing sleeve 6 cooperate to form a labyrinth seal. The compressed air passage 8 is provided in the sealing sleeve, and the compressed air passage 8 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com