Grinding and polishing apparatus and grinding and polishing method

A grinding device and grinding technology, applied in the direction of grinding devices, grinding/polishing safety devices, grinding machine tools, etc., can solve the problems of complexity and large device structure, and achieve the effect of large and complex device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

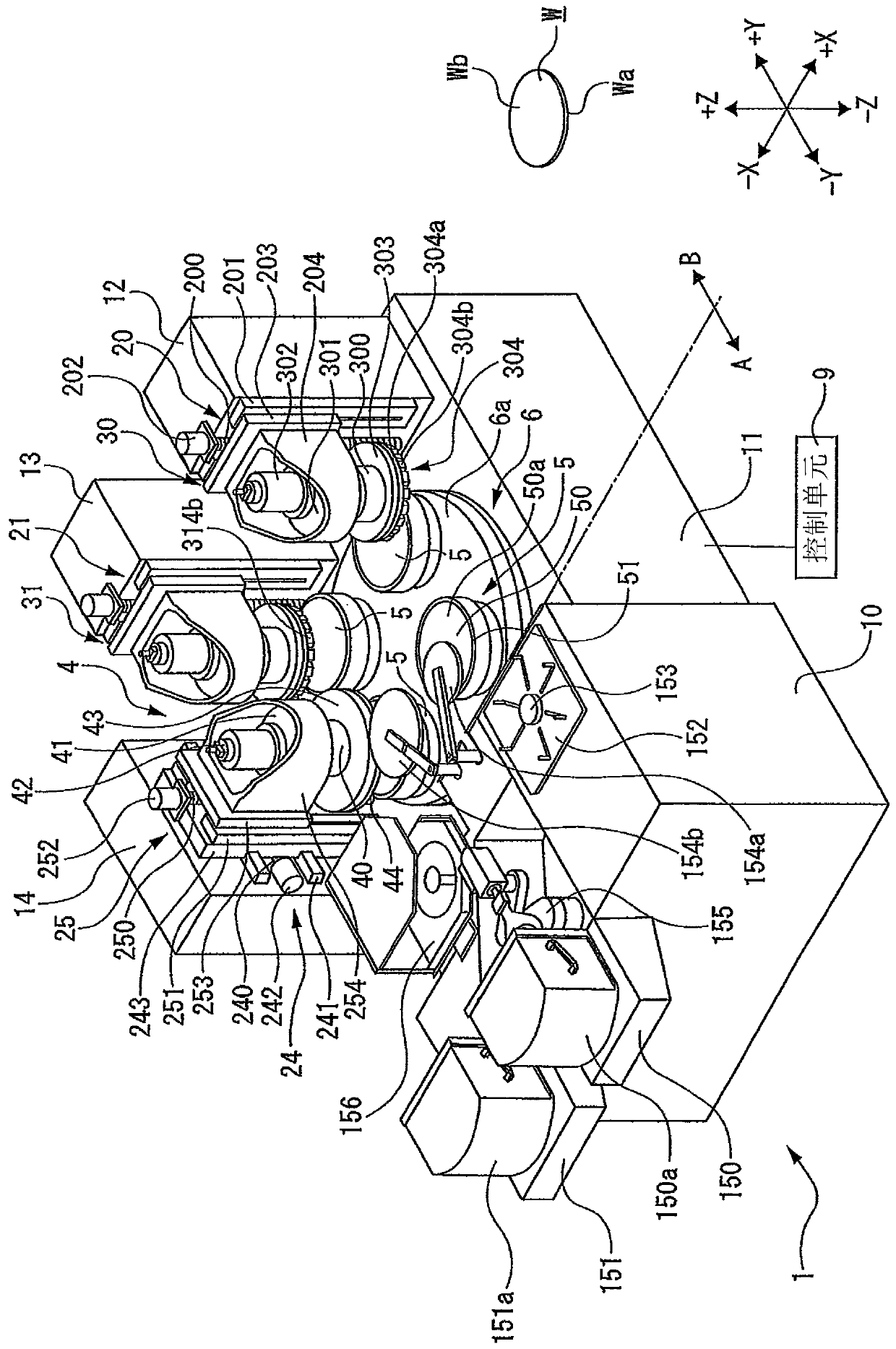

[0020] figure 1 The shown grinding and grinding device 1 is a device as follows: it has a rough grinding unit 30, a fine grinding unit 31 and a grinding unit 4, by which any holding unit 5 is controlled by the rough grinding unit 30 and the fine grinding unit 31. The held wafer W is ground, and the wafer W is ground by the grinding unit 4 .

[0021] The grinding and polishing apparatus 1 is configured such that, for example, the second apparatus base 11 is coupled to the rear (+Y direction side) of the first apparatus base 10 . On the first device base 10 is a loading / unloading area A where loading / unloading of the wafer W and the like are performed. On the second device base 11 is a processing area B where the wafer W held by the holding unit 5 is processed by the rough grinding unit 30 , the finish grinding unit 31 , or the polishing unit 4 .

[0022] figure 1 The wafer W shown is, for example, a circular plate-shaped semiconductor wafer made of a silicon base material or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com