Method of quench hardening and device for use therein

A technology of quenching device and quenching oil, which is applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems of unbalanced heat treatment deformation and unbalanced flow rate, and achieve the goal of suppressing carburizing quality and unbalanced heat treatment deformation, and reducing cooling speed unbalanced, reducing the effect of unbalanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

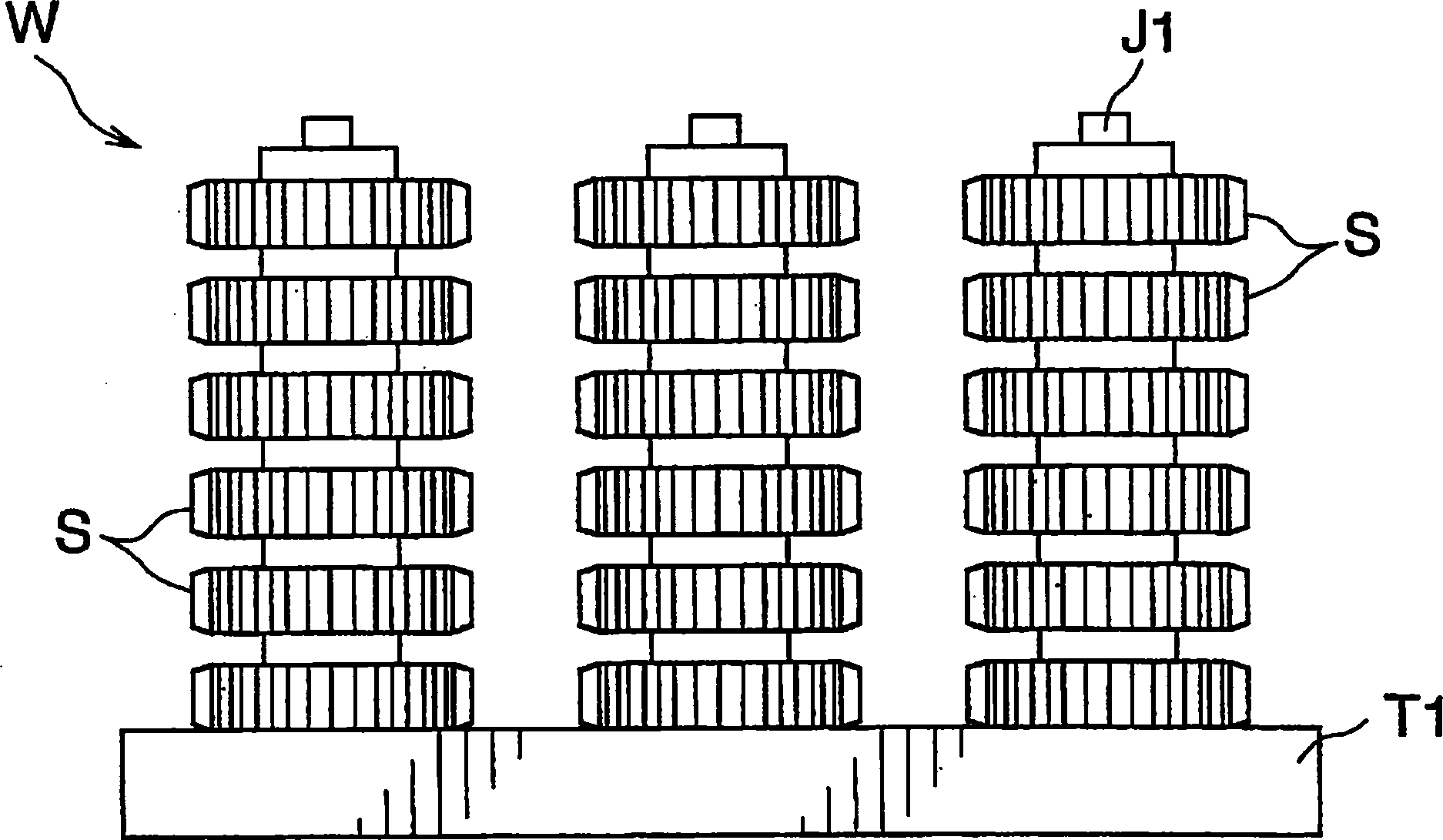

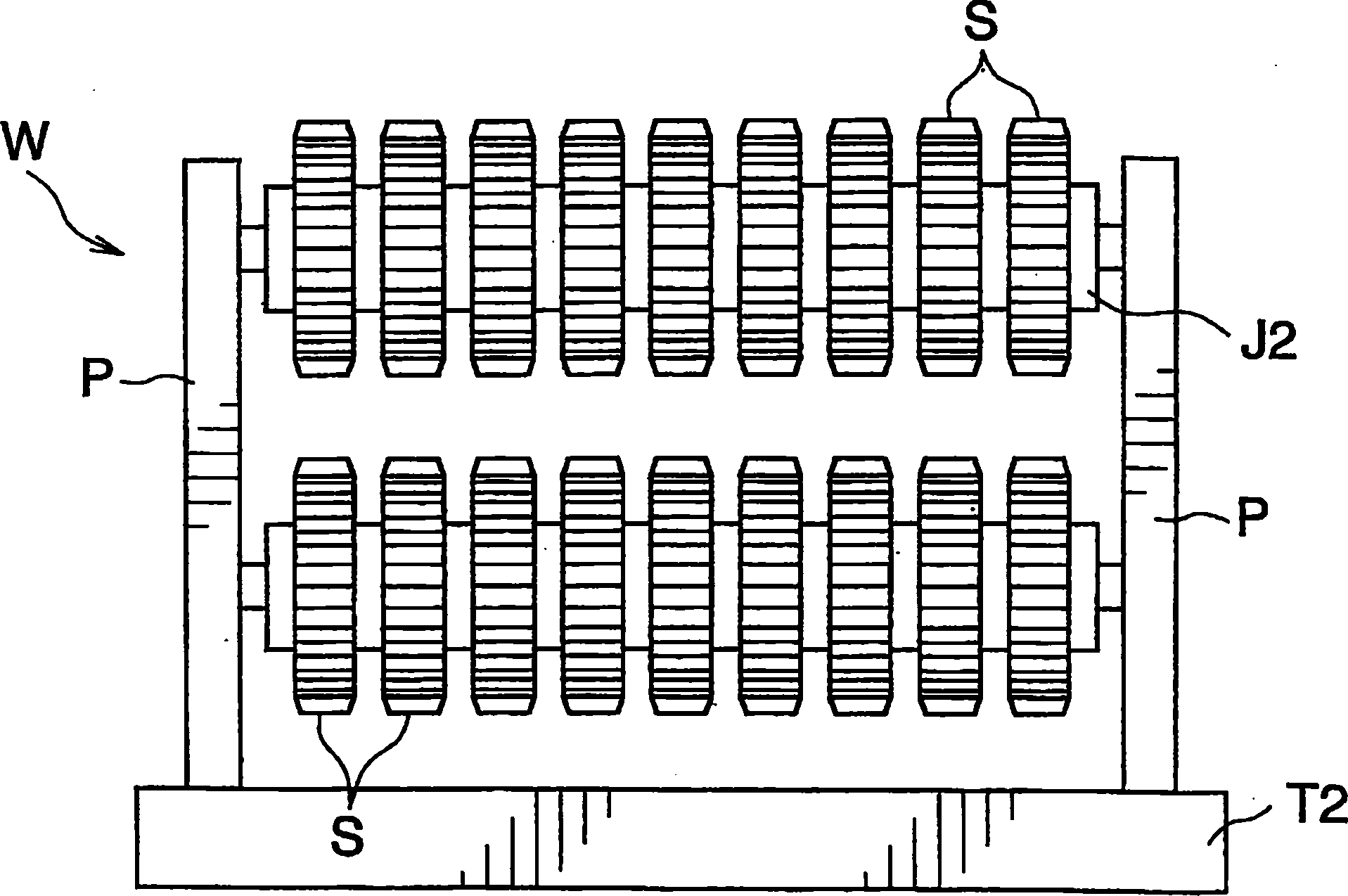

[0027] figure 1 and figure 2 It shows the arrangement of ring-shaped items S to be processed such as gears. figure 1 In , a plurality of vertical bar-shaped jigs J1 are erected on the upper surface of the tray T1 (also in the direction perpendicular to the paper surface). A plurality of items S to be processed are embedded at predetermined intervals on each jig J1. This state is called a flat arrangement. figure 2 Among them, a pair of piles P are erected at both ends of the upper surface of the tray T2, and the horizontal bar-shaped jig J2 is set up on the two piles P and fixed (in the direction perpendicular to the paper surface) with a distance between the upper and lower sides. also available above). A plurality of items S to be processed are embedded at predetermined intervals on each jig J2. This state is called a sideways placement.

[0028] In the case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com