Gas chromatograph

A gas chromatograph and shell technology, applied in the field of gas chromatograph, can solve the problems of shell cooling and inability to cool the first motor efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

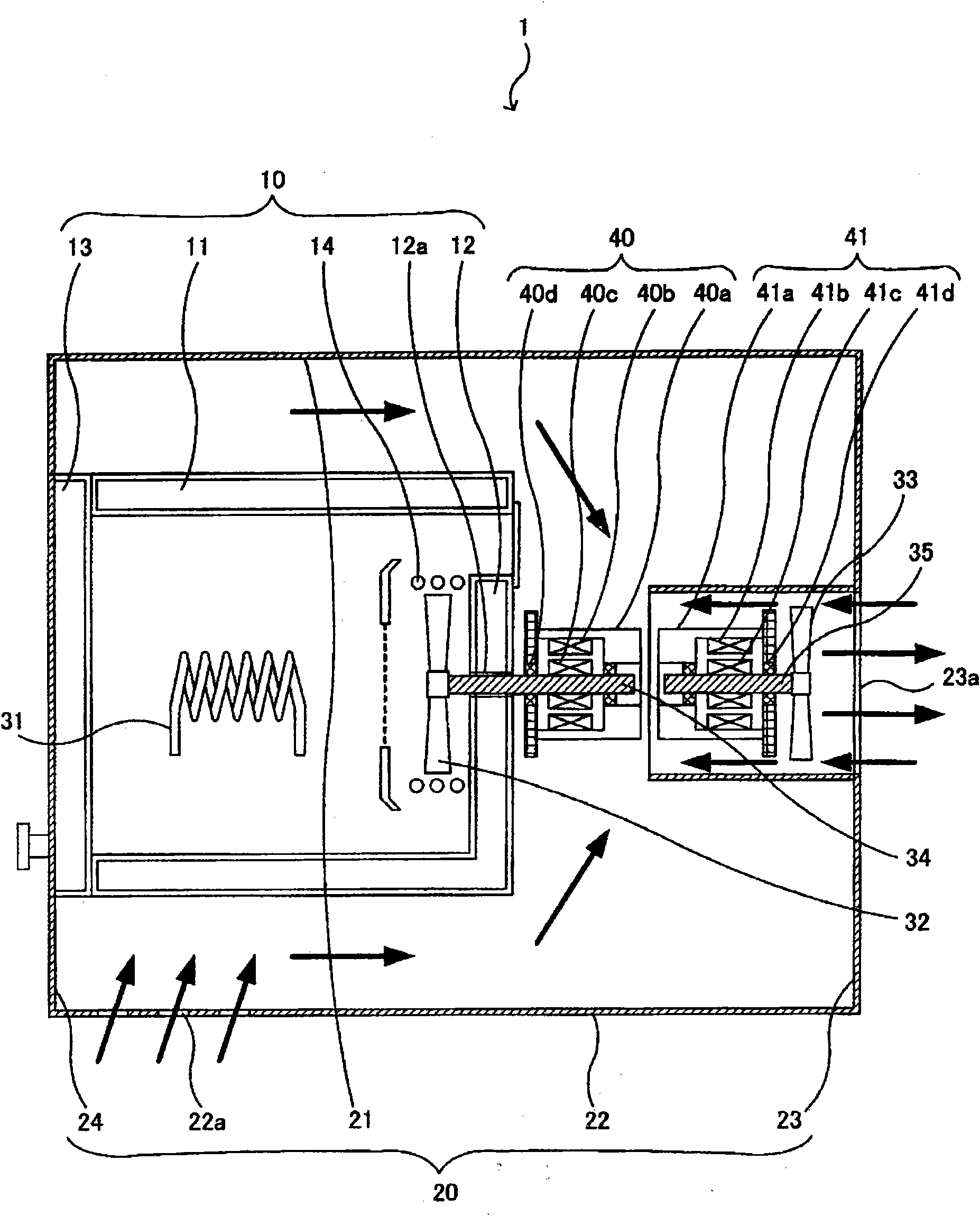

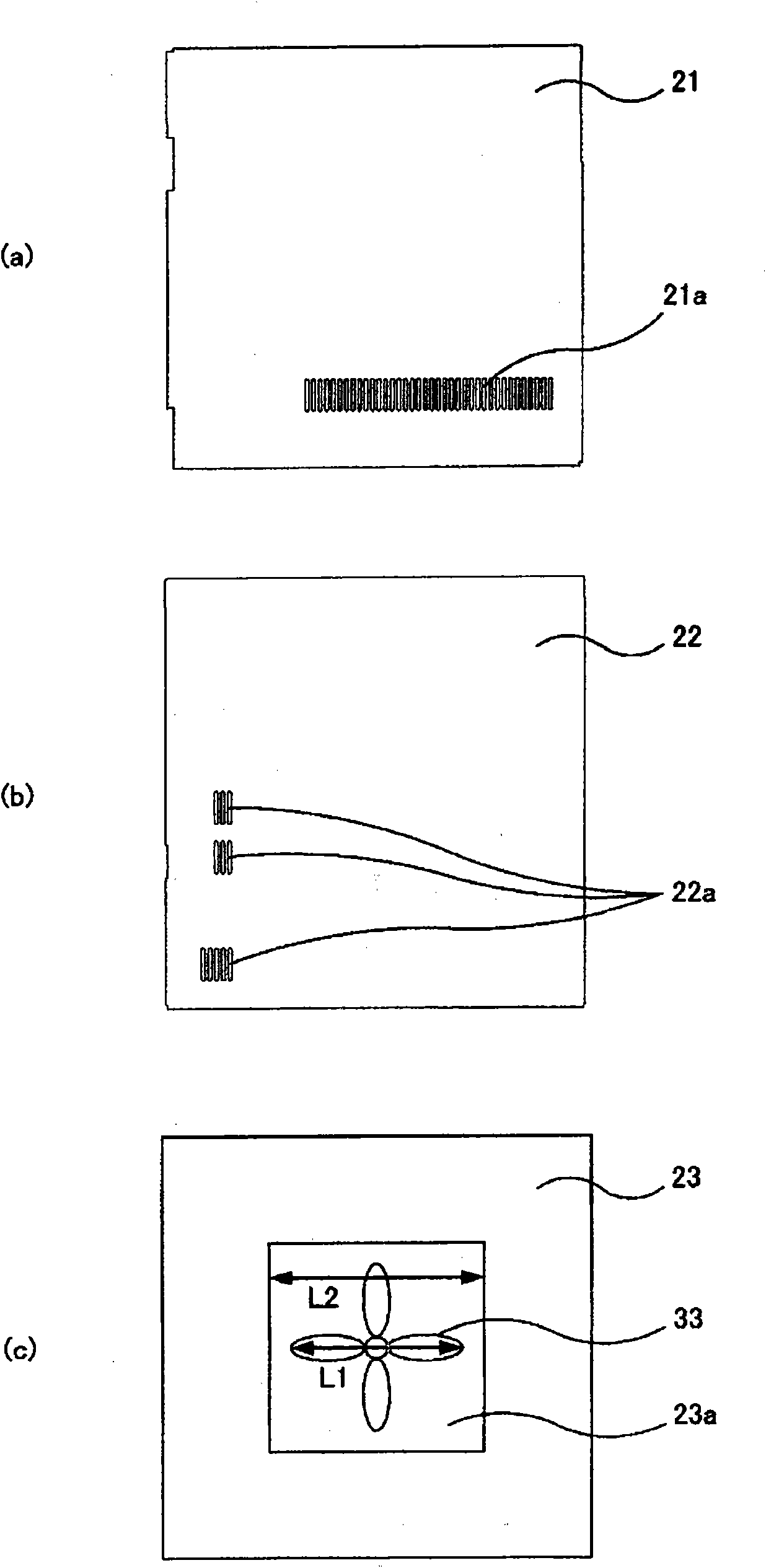

Method used

Image

Examples

Embodiment approach

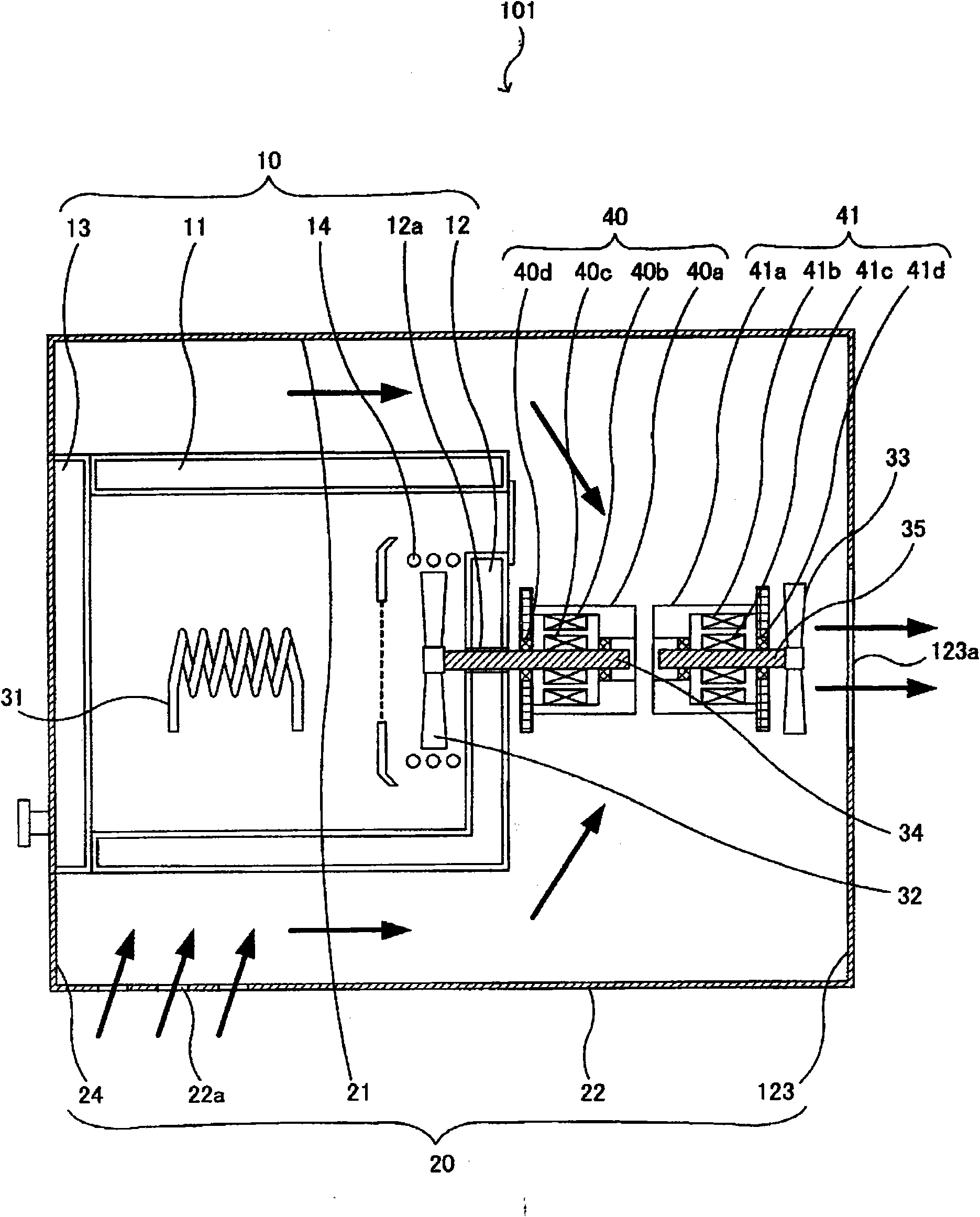

[0055] (1) In the above-mentioned gas chromatograph 1, the structure in which the second vane 33 and the second motor 41 are arranged inside the tube 23b is shown, but it may be configured such that the second vane, the second motor 41 are arranged inside the tube. Such a structure of the second electric motor and the first electric motor.

[0056] (2) In the gas chromatograph 1 described above, the first motor 40 and the second motor 41 are separately provided, but it is also possible to configure the first motor by connecting the first shaft and the second shaft. One motor integrated with the second motor.

[0057] The present invention can be used in a gas chromatograph for accommodating a chromatographic column in an incubator and adjusting the temperature of the chromatographic column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com