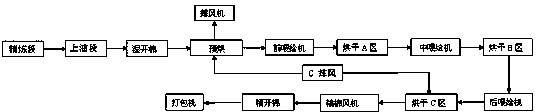

High-capacity viscose staple fiber post-treatment production line

A viscose staple fiber, large-capacity technology, applied in the field of viscose staple fiber, can solve the problems that the system cannot realize automatic adjustment, the cyclone conveying cannot be effectively adjusted, and the equipment cannot be used normally for a long time, so as to achieve cost control, fine bleaching, and reduce The effect of Ph

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

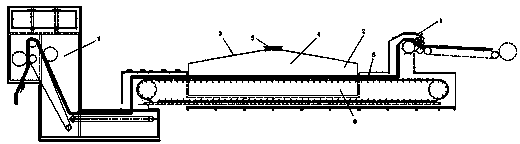

[0054] A large-capacity viscose staple fiber post-processing production line, including a refining system and a drying system. The refining machine in the refining system includes a refining section and an oiling section. The width of the refining machine in the refining system is 4000mm. The refining section It is divided into 13 process areas, and the oiling section is divided into 2 process areas, and the length of each area is 2500mm.

[0055] The refining section includes: 2 process areas for primary washing, 4 process areas for desulfurization, 2 process areas for secondary washing, 1 process area for bleaching, and 2 process areas for tertiary washing.

Embodiment 2

[0057] A large-capacity viscose staple fiber post-processing production line, including a refining system and a drying system. The refining machine in the refining system includes a refining section and an oiling section. The width of the refining machine in the refining system is 4000mm. The refining section It is divided into 18 process areas, and the oiling section is divided into 2 process areas, and the length of each area is 2500mm.

[0058] The refining section includes: 3 process areas for primary washing, 2 process areas for desulfurization, 5 process areas for secondary washing, 3 process areas for bleaching, and 5 process areas for tertiary washing.

Embodiment 3

[0060] A large-capacity viscose staple fiber post-processing production line, including a refining system and a drying system. The refining machine in the refining system includes a refining section and an oiling section. The width of the refining machine in the refining system is 4000mm. The refining section It is divided into 15 process areas, and the oiling section is divided into 2 process areas, and the length of each area is 2500mm.

[0061] The refining section includes: 3 process areas for primary washing, 3 process areas for desulfurization, 4 process areas for secondary washing, 2 process areas for bleaching, and 3 process areas for tertiary washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com