Patents

Literature

55 results about "Fiber posts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrated fiber post for dental restoration and preparation method thereof

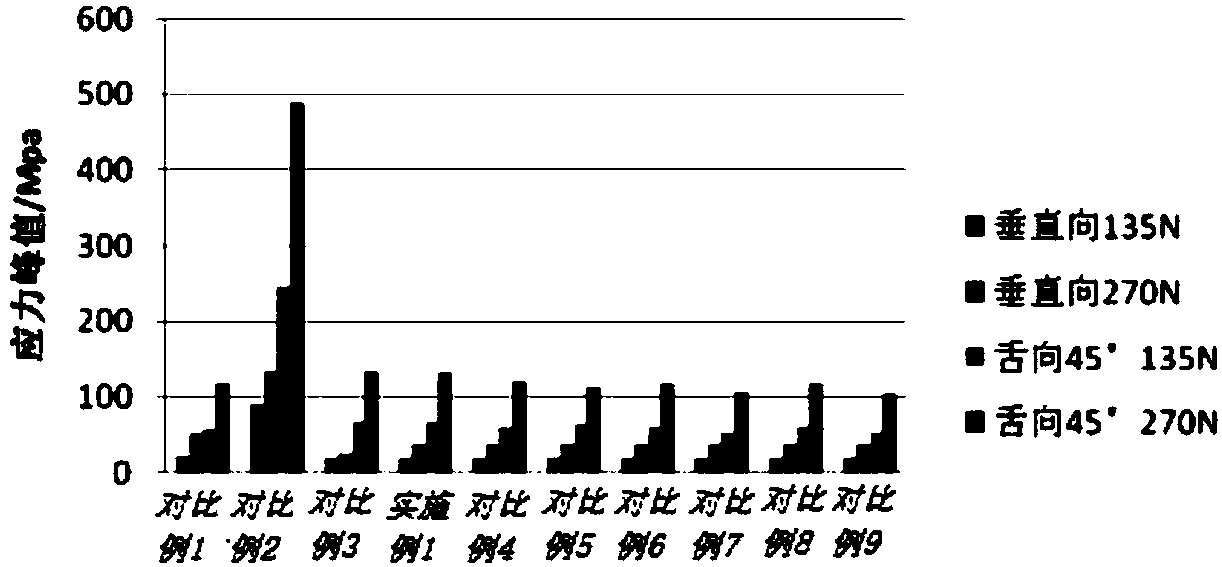

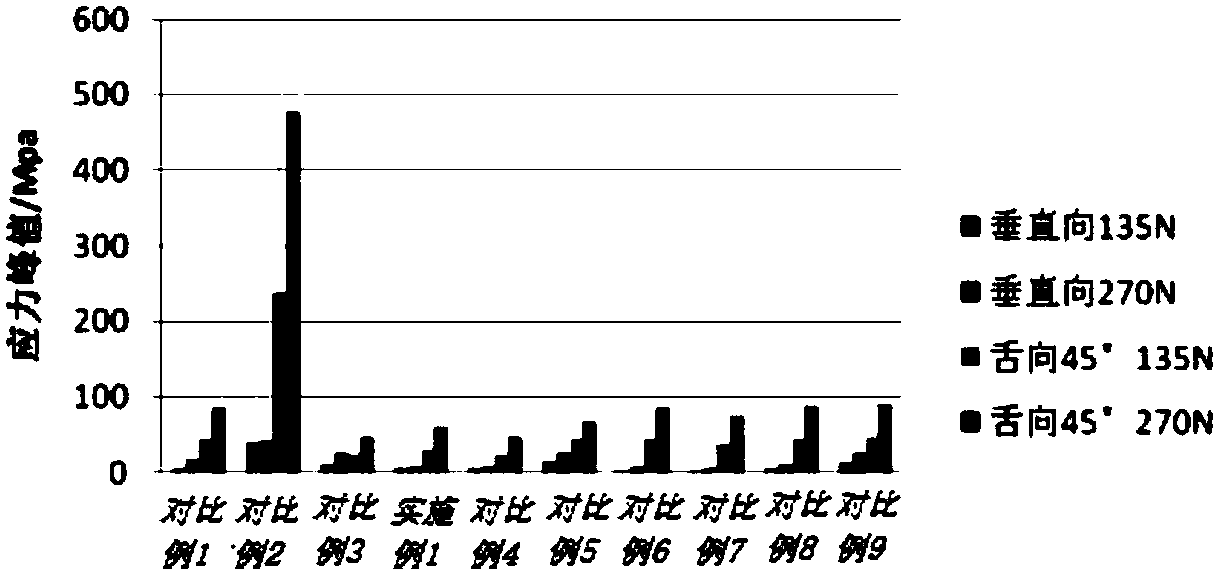

ActiveCN101803958AHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlStress concentration

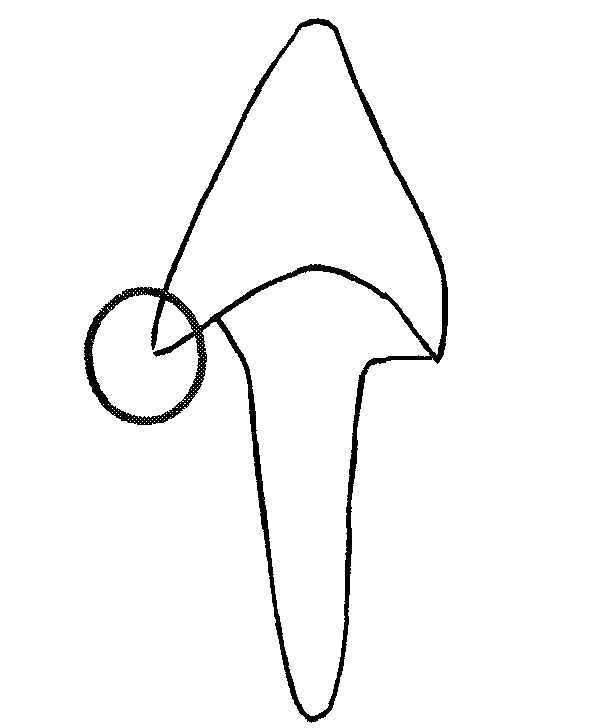

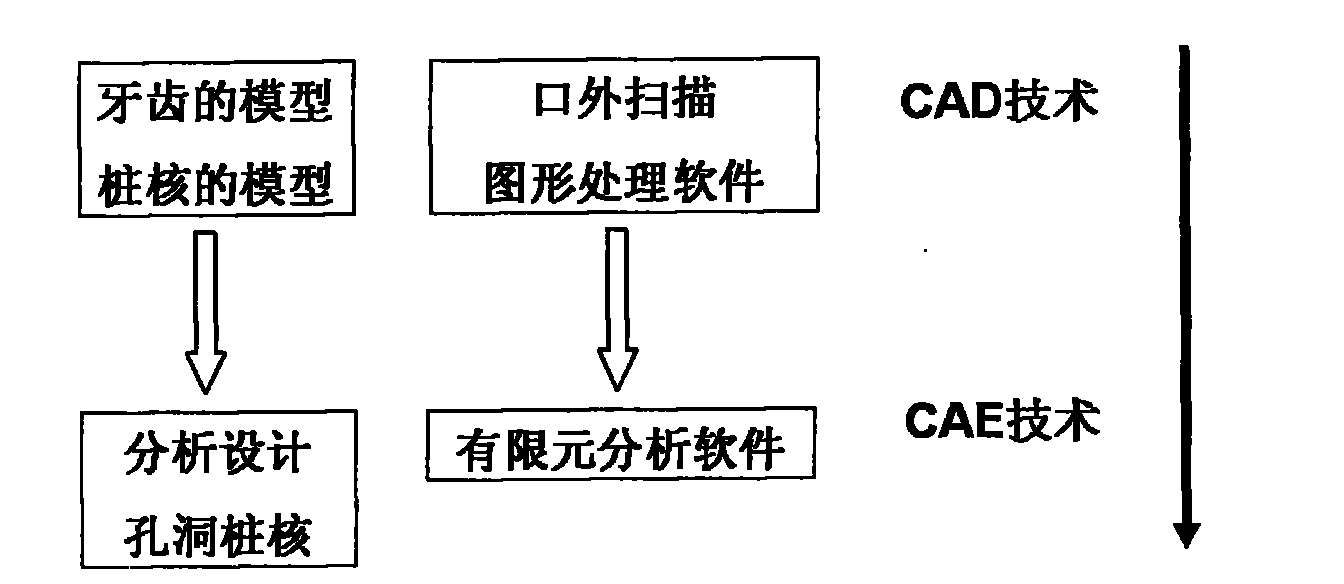

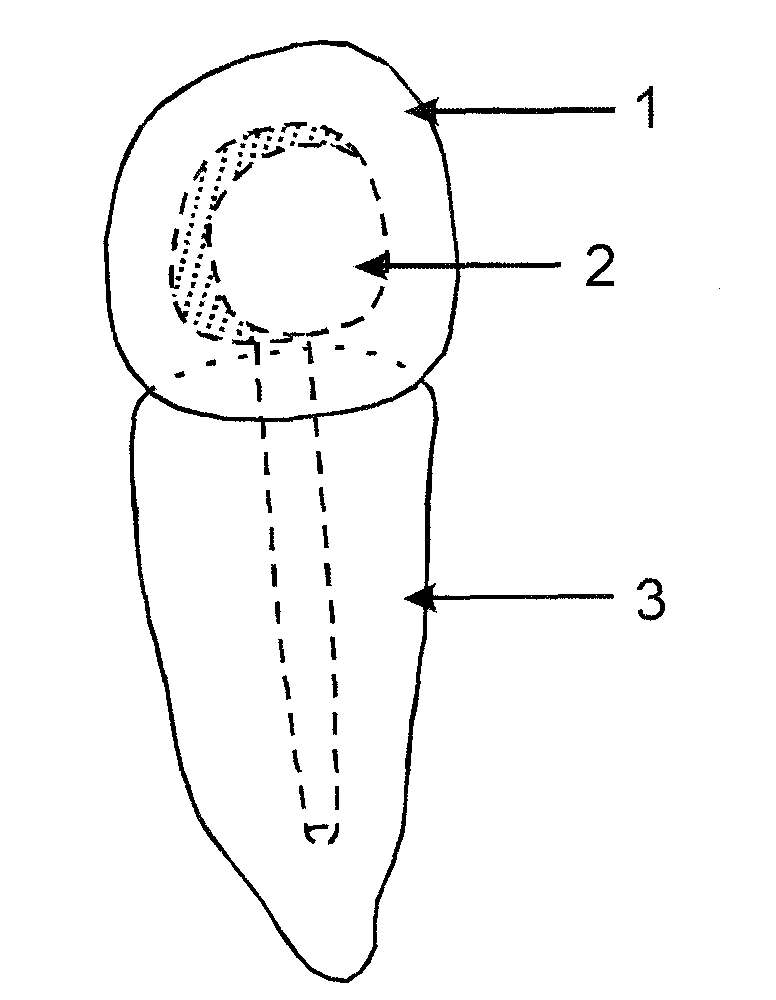

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aideddesign) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

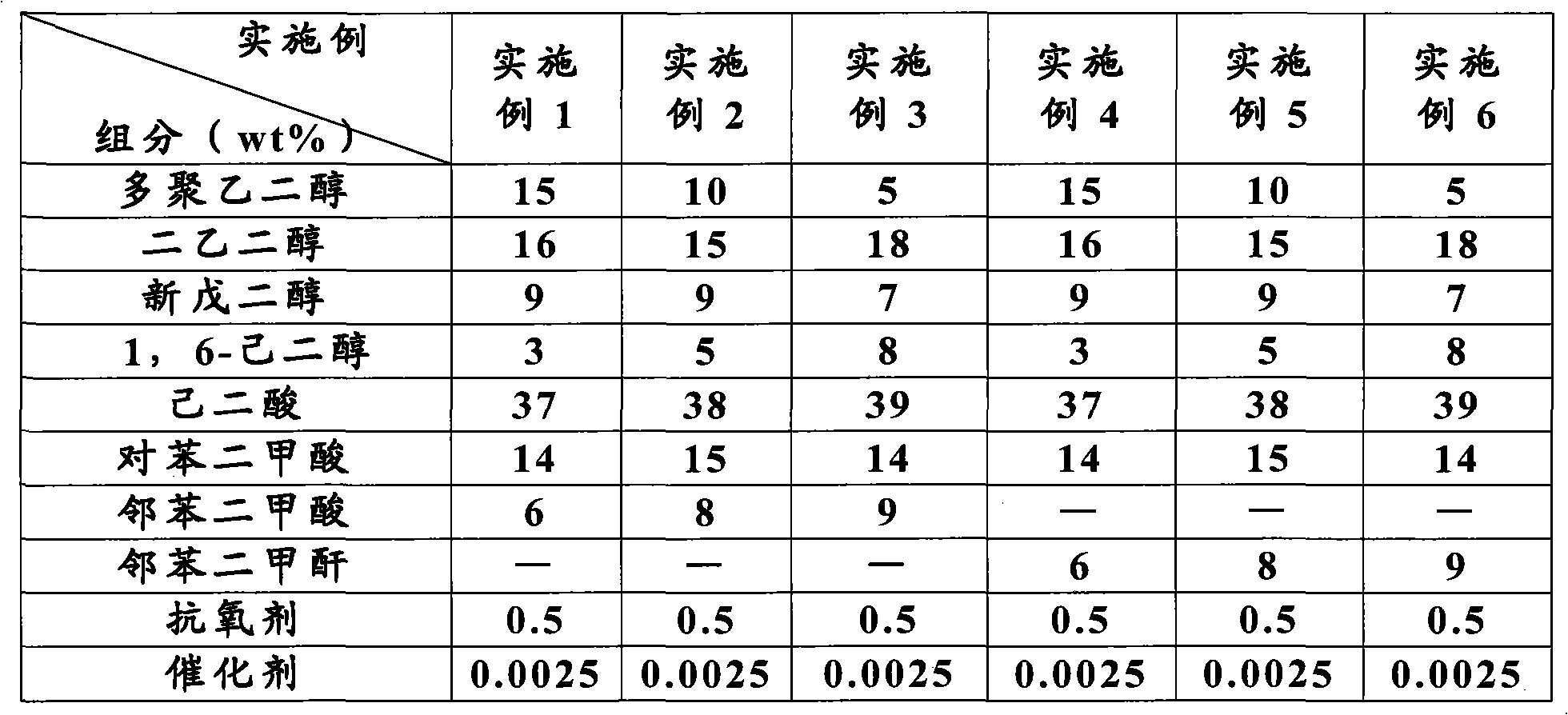

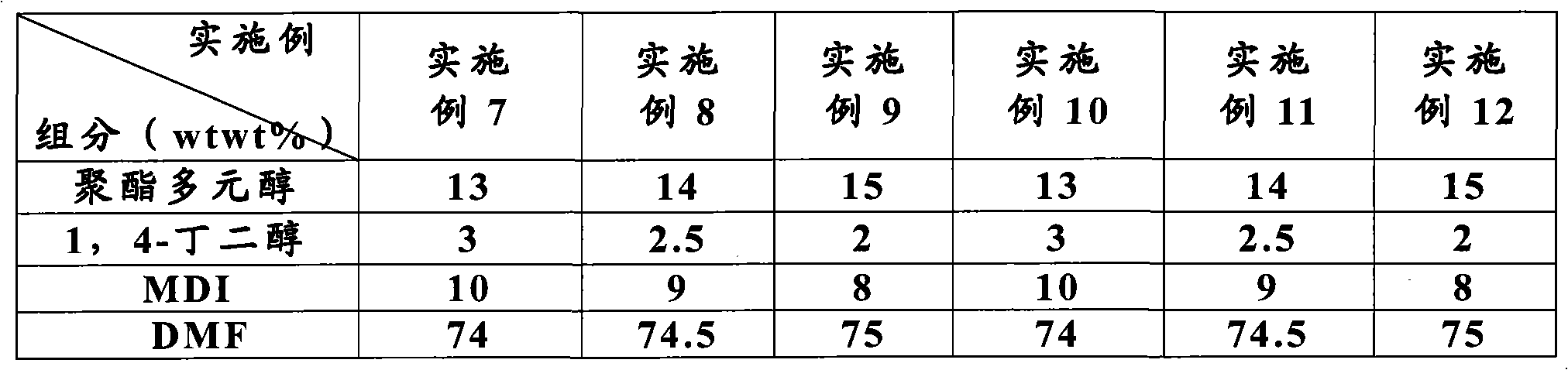

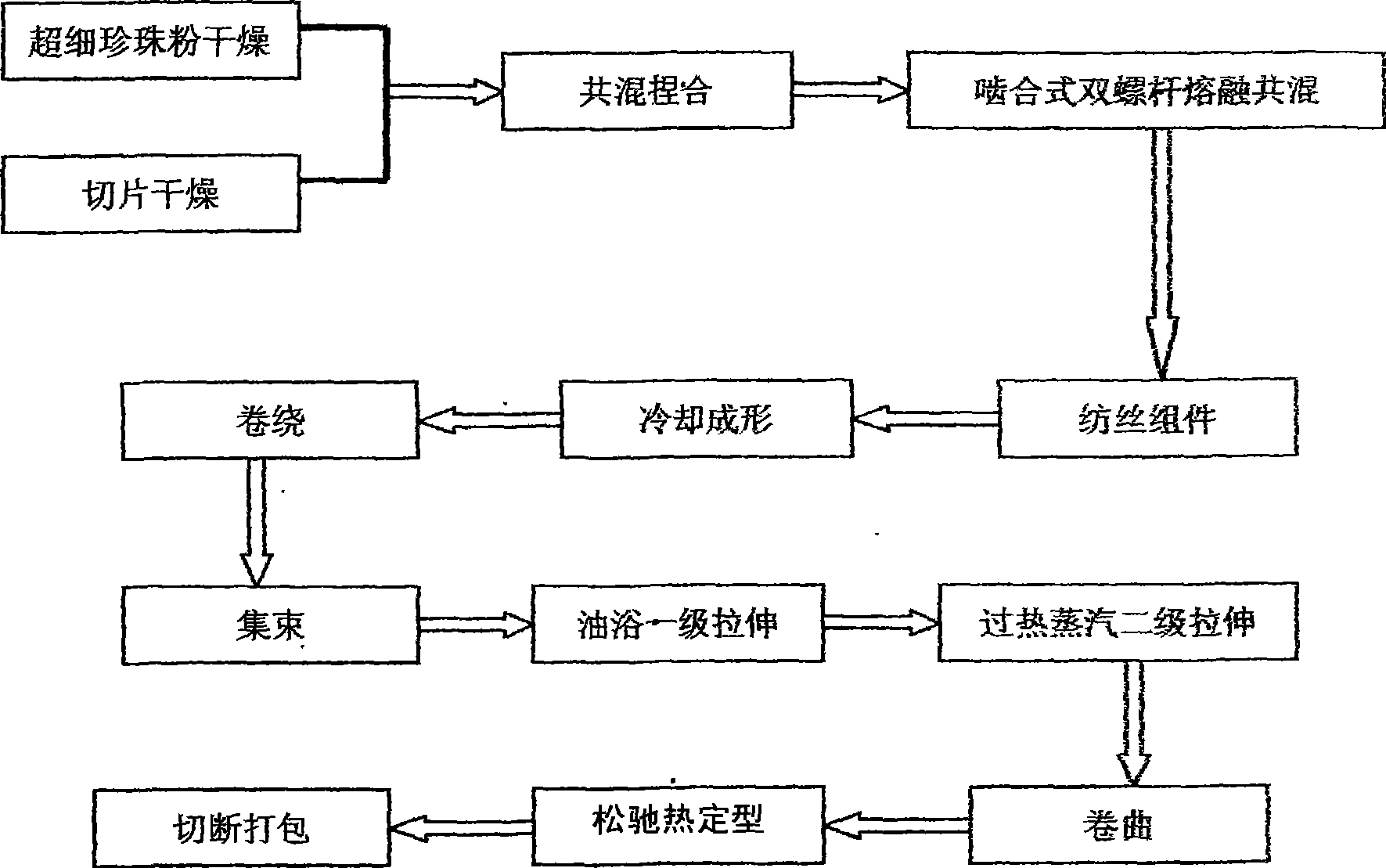

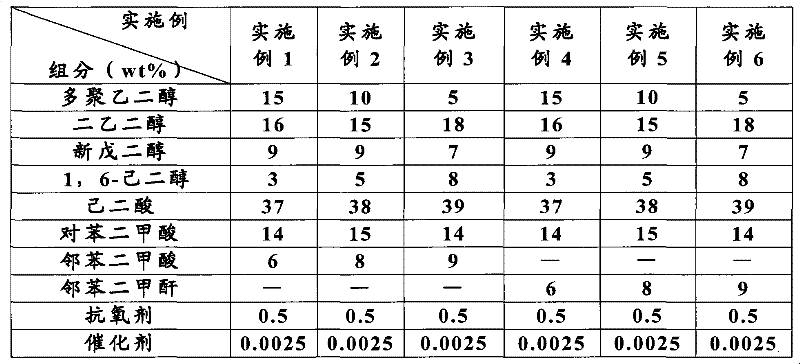

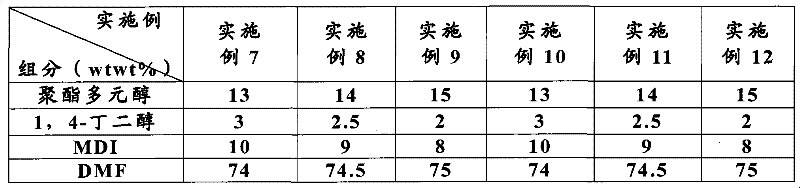

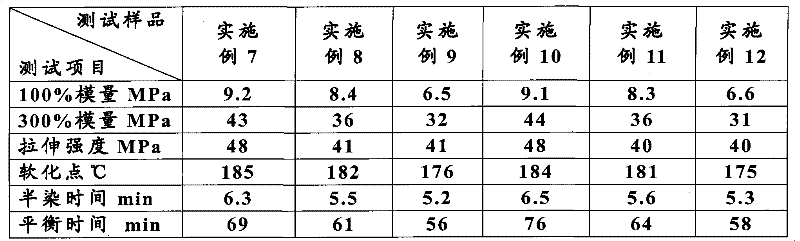

Polyester polyol and polyurethane resin for superfine fiber synthetic leather

The invention relates to polyester polyol for synthesizing a polyurethane resin for superfine fiber synthetic leather and the polyurethane resin synthesized by polyester polyol. The polyester polyol comprises the following starting materials: 5-15wt% of polyethylene glycol, 50-65wt% of mixed dicarboxylic acid and 15-35wt% of mixed diols. The assistants adopted during synthesis include a catalyst and an antioxidant. The polyurethane resin synthesized by polyester polyol obtained by adopting the technical scheme is especially suitable for processing the superfine fiber post-dyed synthetic leathers, the degree of dyeing of the polyurethane resin for superfine resins is improved, the polyurethane resin is not easy to decolor and polyester polyol has high moisture absorption, thus ensuring the final superfine resin products to have good handfeel.

Owner:XUCHUAN CHEM SUZHOU

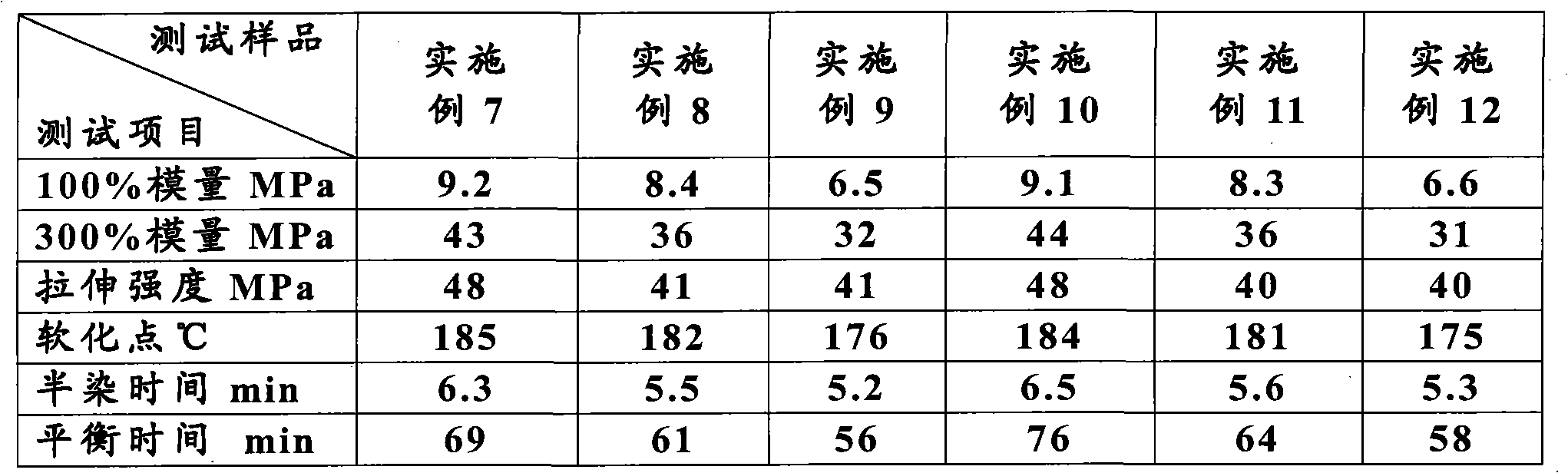

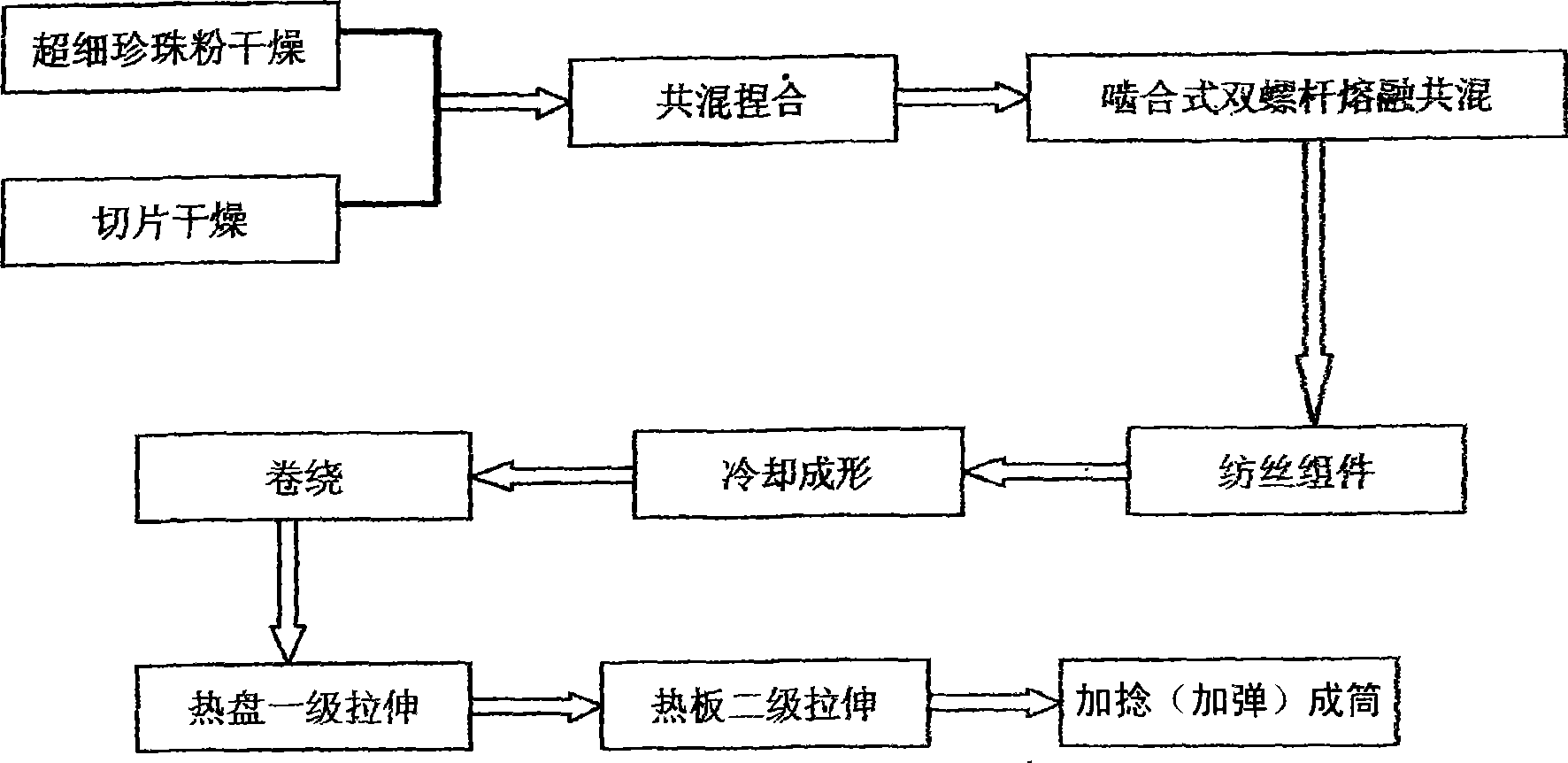

Engaging double-screw rod spinning pearl functional fibre and manufacturing process thereof

InactiveCN101481830AQuality improvementQuality assuranceMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentMetallurgyAntioxidant

The invention discloses a meshing twin-screw spinning pearl functional fiber and a manufacturing process thereof. A formula of the spinning pearl functional fiber by weight is as follows: 94-99% of melt spinning slices; 1-6% of pearl powder having average particle diameter less than 1mum; 0.1-3% of a surfactant and 0.1-3% of an antioxidant. The process comprises the following steps: the materials are placed in a mixer according to component proportions, added with the surfactant and the antioxidant 1010, then the mixture obtained is sent to an meshing twin-screw machine to be fused and mixed after being kneaded in the mixer, then is sent to a spinning manifold by the connection of a flange bend to directly spin, and a blending melt is spun from a spinneret plate through a spinning pack, and is wound into primary pearl functional fiber raw silk after cooling blow. Then the primary raw silk is subject to twice stretching and heat setting in packing or a single cylinder according to a filament or staple fiber post-processing procedure. Primary stretching of the filament is carried out on a hot disk, and secondary stretching of the filament is carried out on a hot plate; the primary stretching of the staple fiber is carried out in oil bath, and the secondary stretching is carried out by superheated steam. The manufacturing process is applicable to spinning pearl functional fibers.

Owner:吴张江

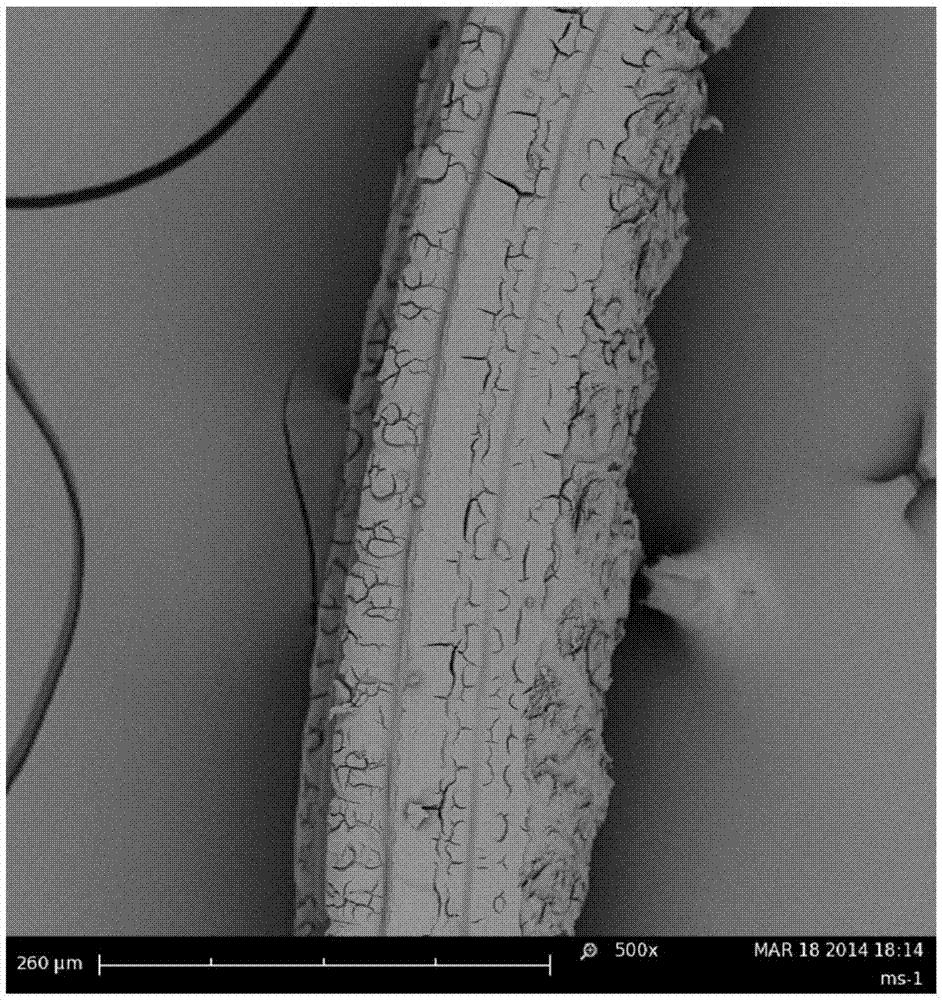

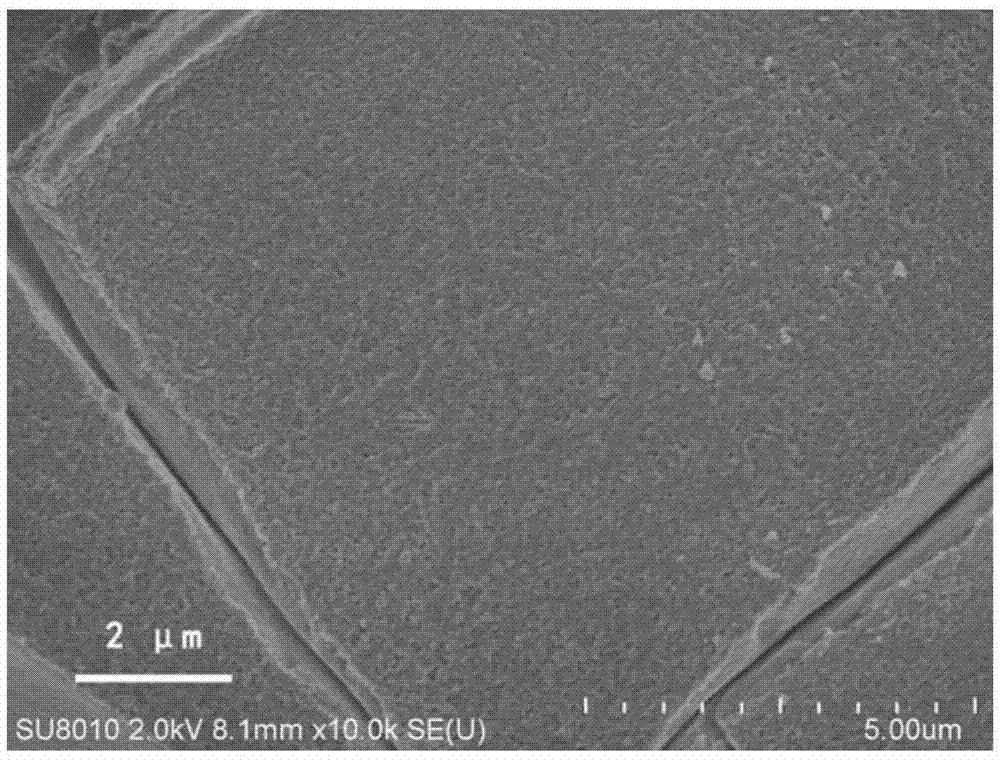

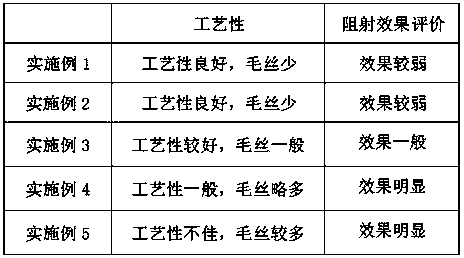

Preparation method of quartz fiber with X-ray radiation prevention agent coating

ActiveCN106316159AUniform X-ray opacity performanceImprove the effect of blocking X-raysGlass making apparatusEpoxyCooking & baking

The invention relates to a preparation method of quartz fiber with X-ray radiation prevention agent coating, and belongs to the technical field of quartz fiber production. Surface of quartz fiber filament is treated using the surface treating agent containing radiation prevention agent, then quartz fiber filament is coiled to quartz fiber strand by the high speed rotation and traction of the head of drawing mill, and finally, the strand is subjected to baking, degradation, pre-twist and cabling to form the final product of quartz fiber yarn with a coating containing radiation prevention agent. The quartz fiber with a coating containing radiation prevention agent made using such method has the strengths of simple techniques and low cost, and can well combined with epoxy, and can be produced to the fiber post with homogeneous X-ray prevention effect.

Owner:HUBEI FEILIHUA QUARTZ GLASS

Application of folium artemisiae argyi pigment dye to cotton fiber post-mordant dyeing process

The invention provides application of folium artemisiae argyi pigment dye to a cotton fiber post-mordant dyeing process. Cotton fiber is dyed with the dye through a post-mordant dyeing method, so folium artemisiae argyi pigment can serve as plant dye of the cotton fiber; moreover, a dyeing process which applies the folium artemisiae argyi pigment dye to cotton fiber dyeing and has an industrialized application value is provided; and by the post-mordant dyeing method of pure cotton fiber, the color depth K / S value of cotton fabric reaches 4.215, unlubricated friction reaches level 4 to 5, wet friction reaches level 4, color change reaches level 4, staining (cotton) reaches level 4 to 5 and hand feeling reaches level 4, the actual industrial production requirements are met, and the technological gap of folium artemisiae argyi pigment plant dye in the prior art is filled.

Owner:HUNAN INSTITUTE OF ENGINEERING

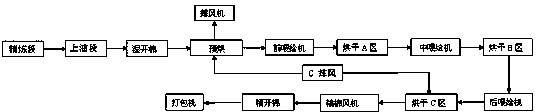

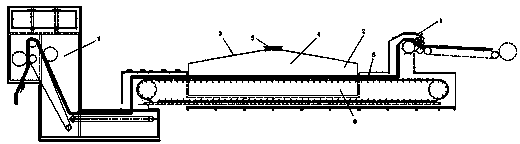

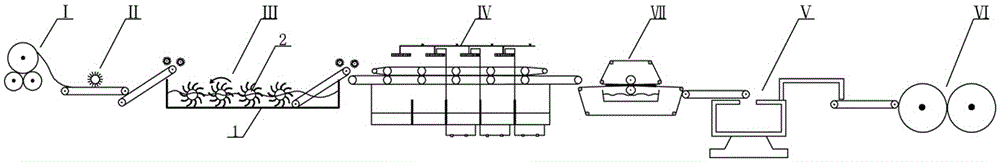

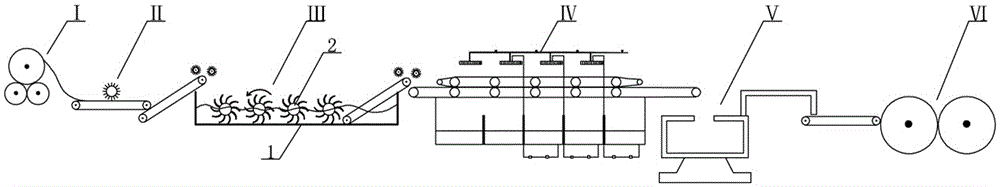

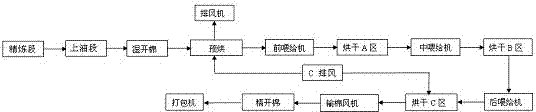

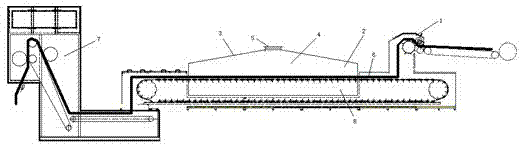

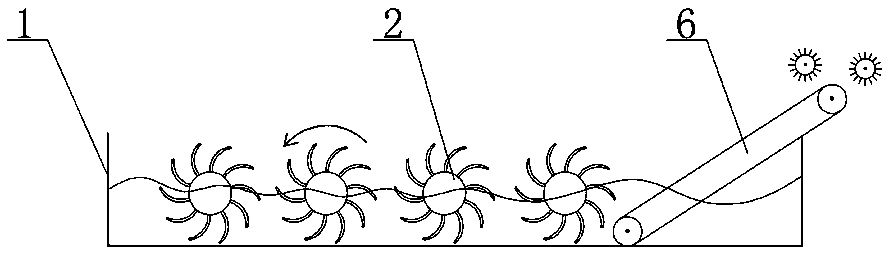

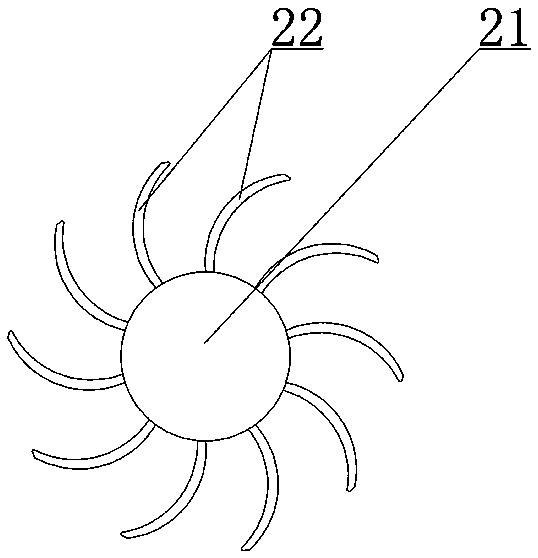

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290AIncrease washing timeWash Time GuaranteeSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

Preparation method of tough SiO2 aerogel fibers post-processed through isocyanate

ActiveCN105442099AAdjust the size of the specific surface areaTo achieve toughening and strengtheningInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberPolymer science

The invention relates to a preparation method of tough SiO2 aerogel fibers post-processed through isocyanate. The preparation method comprises steps as follows: a spinning solution is prepared from silicate or silanol sol; an acid solution is used for a coagulating bath; the spinning solution is added to the coagulating bath, the mixture has a reaction, wet spinning is performed, orthosiliconic acid / silicate fibers are obtained, wound, aged, washed, soaked in a tetrahydrofuran solution of isocyanate for 48 h, then taken out and washed with acetone, solvent replacement is performed through water or ethanol, and the tough SiO2 aerogel fibers are obtained after drying. The method has the characteristics that the raw materials are cheap and easy to obtain, the reaction process is simple, and the spinnability is good; the SiO2 aerogel fibers are toughened through high polymers, the prepared tough SiO2 aerogel fibers have rich pores, a high specific surface area and certain toughness and is high-temperature-resistant and chemical-corrosion resistant, and the specific surface area of the fibers is adjustable.

Owner:DONGHUA UNIV

Technique for preparing lotus fiber by joint process

InactiveCN106480510ALow priceEasy to operateVegetable materialMechanical fibre separationFiberChemical treatment

The invention provides a technique for preparing lotus fiber by a joint process and belongs to the field of fiber extraction and processing. The technique mainly comprises material sorting, chemical treatment, mechanical separation, and fiber post-finishing. The chemical treatment mainly includes: degumming and removing impurities with a strong alkali, and dissolving lignin and skin with chlorite solution to obtain lotus fiber 3-6 Mum in diameter, with impurity removal rate reaching 85% and above. The technique employs chemical treatment and mechanical processing in conjunction with ultrasonic technology to effectively destroy the skin of lotus stems, and the production efficiency is improved. The technique has high efficiency, simple process and good operational simplicity, is low in production cost and short in production cycle, is a novel, efficient, scientific and operable lotus fiber preparation process and has a promising application prospect.

Owner:SICHUAN UNIV

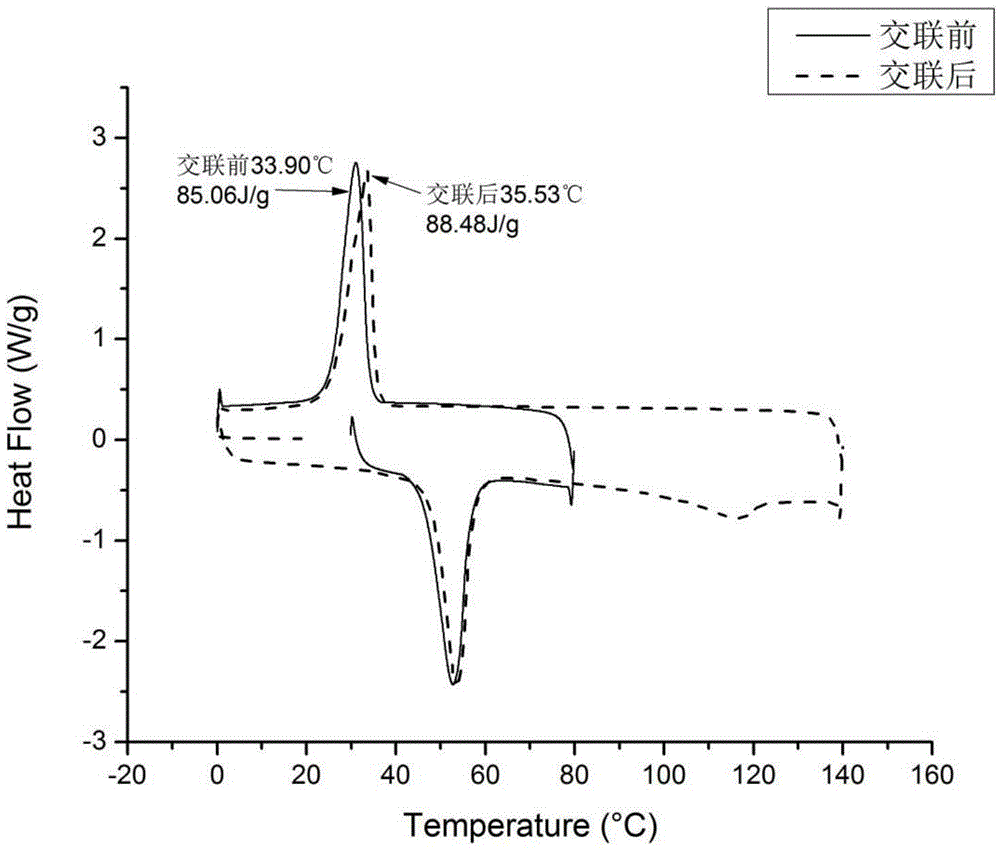

Solid-solid phase-change composite fiber with skin-core structure and online cross-linked core layer and preparation method of solid-solid phase-change composite fiber

ActiveCN105648578ASolve processabilityPrevent leakageArtificial filament heat treatmentWet spinning methodsCross-linkPolyethylene glycol

The invention relates to the technical field of phase-change energy storage materials, and in particular relates to a solid-solid phase-change composite fiber with a skin-core structure and an online cross-linked core layer and a preparation method of the solid-solid phase-change composite fiber. With alginate as a skin layer, and allyl polyethylene glycol, triallyl isocyanurate and an initiator as a core layer, the composite fiber with the skin-core structure is obtained by a wet spinning technique, thermal treatment is carried out in the fiber post-processing process, and then the core layer is subjected to cross-linking reaction to obtain the composite fiber with the solid-solid phase-change material of the cross-linked structure as the core layer and the alginate as the skin layer. The fiber is good in stability, high in crystalline enthalpy and simple in preparation method and has a good application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

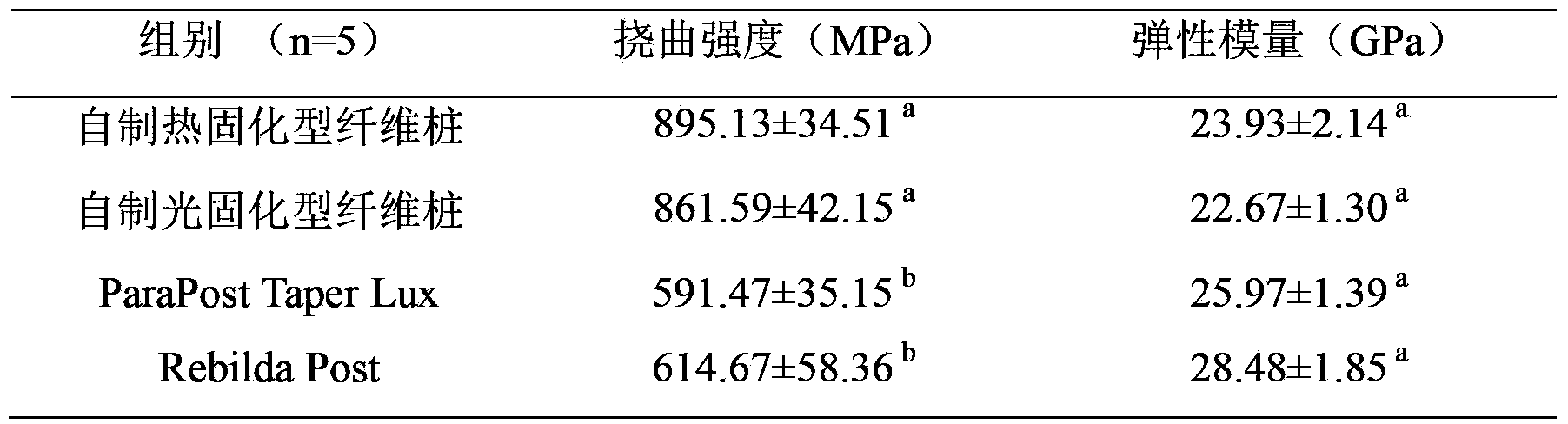

Fiber reinforced composite material for dental root canal post and preparation method thereof

InactiveCN104095760AGood mechanical propertiesImprove flexibilityImpression capsPhysical treatmentResin matrixFiber-reinforced composite

The invention relates to a poly(p-phenylene benzobisoxazole) (PBO) fiber reinforced composite material for a dental root canal post and a preparation method thereof. The fiber reinforced composite material for the dental root canal post comprises a surface modified PBO reinforced fiber which is used as a reinforcing phase and a nanometer modified toughening resin which is used as a matrix. The composite material is compounded by mixing the PBO reinforced fiber with the toughening resin, wherein the PBO reinforced fiber adopts a 3D braided structure. According to the invention, a breakthrough is made to the design of unidirectional reinforcement with single-phase fibers in conventional fiber post structures, the high-performance PBO fiber and the 3D braided structure are introduced into a dental post material, so the flexural behavior of a conventional fiber post is improved, and good interfacial bonding force between the high-performance fiber and the resin matrix is guaranteed; and through adoption of the 3D braided structure, layering of the laminated composite material is effectively avoided, so excellent mechanical properties of the composite material in vertical, transverse and thickness directions are guaranteed.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

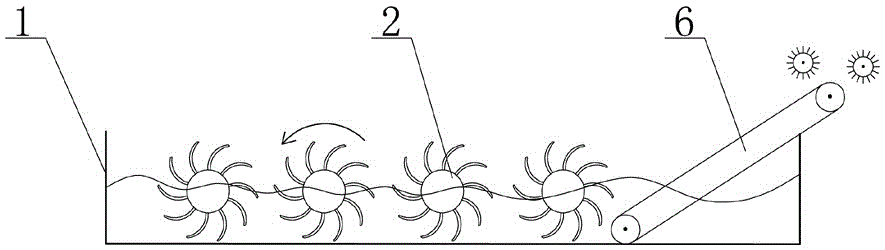

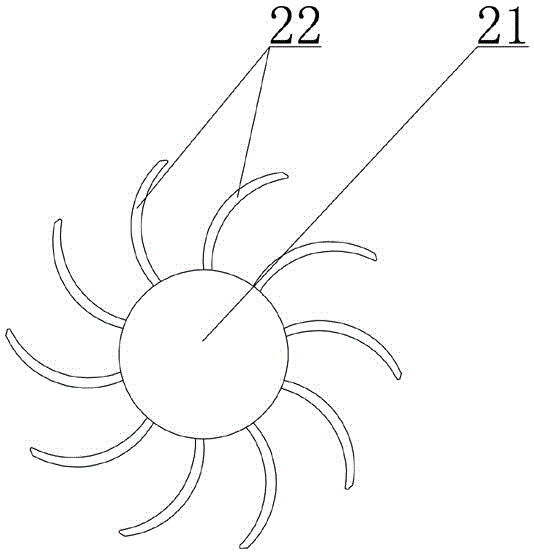

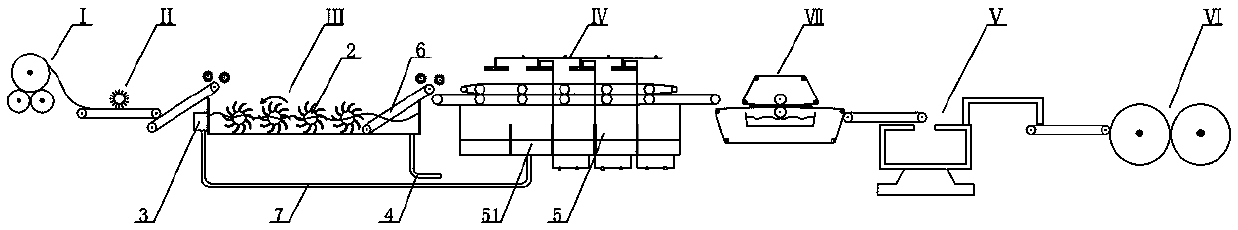

Continuous loose fiber post-processing technology

InactiveCN105040322AFully contactedShorten the lengthSucessive textile treatmentsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberSmall footprint

The invention discloses a continuous loose fiber post-processing technology. The continuous loose fiber post-processing technology comprises the steps of opening, soaking type cleaning, sprinkling-rolling type water washing, squeezing, dehydration, drying and the like. The continuous loose fiber post-processing technology has the advantages that a processing device is small in occupied area, production cost is low and the like.

Owner:SHAOXING GUOZHOU HLDG GRP CO LTD

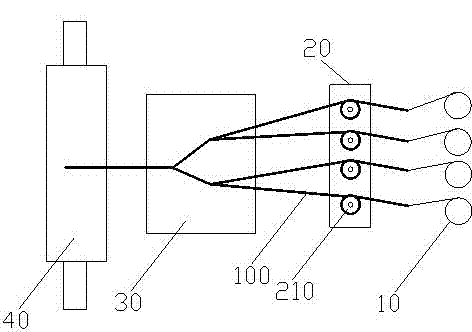

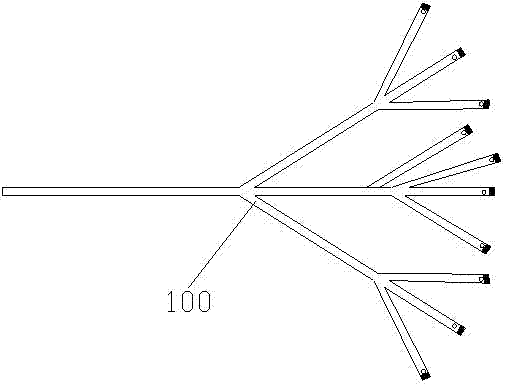

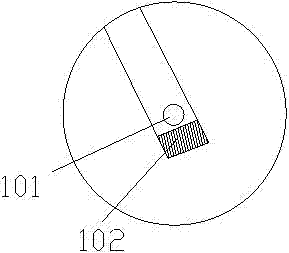

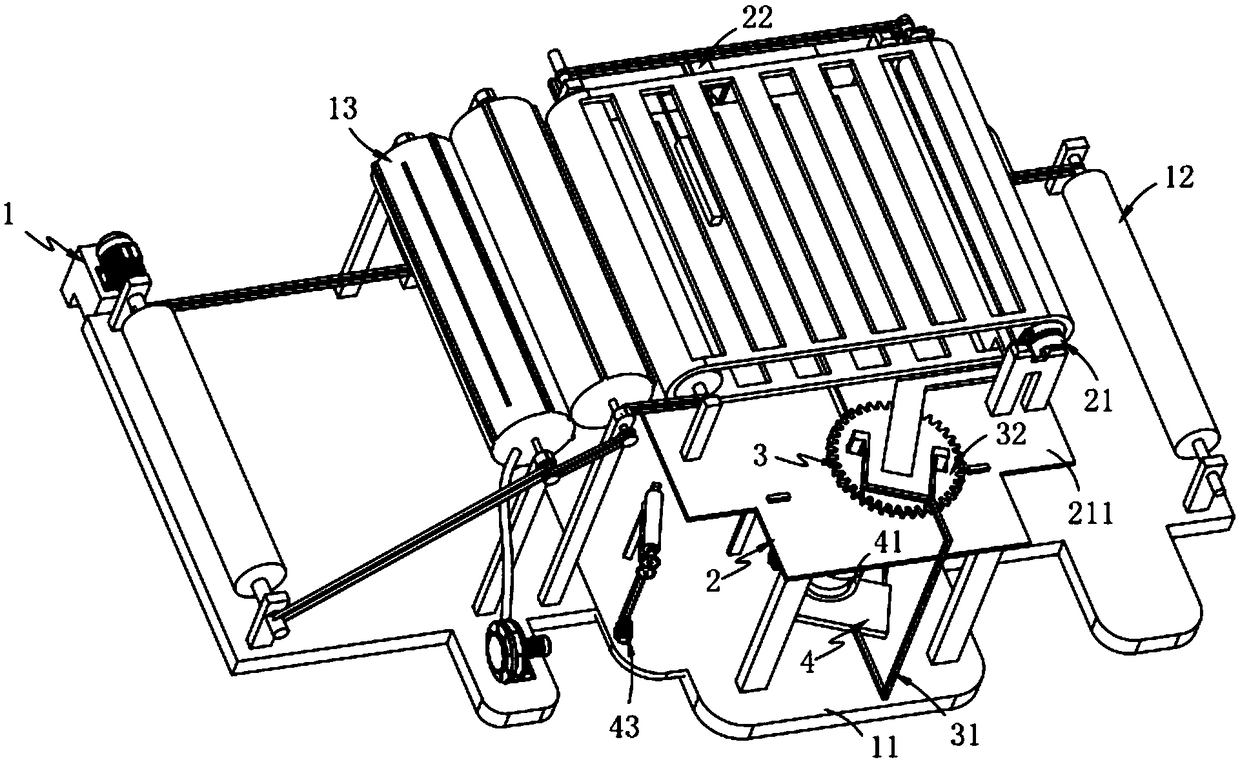

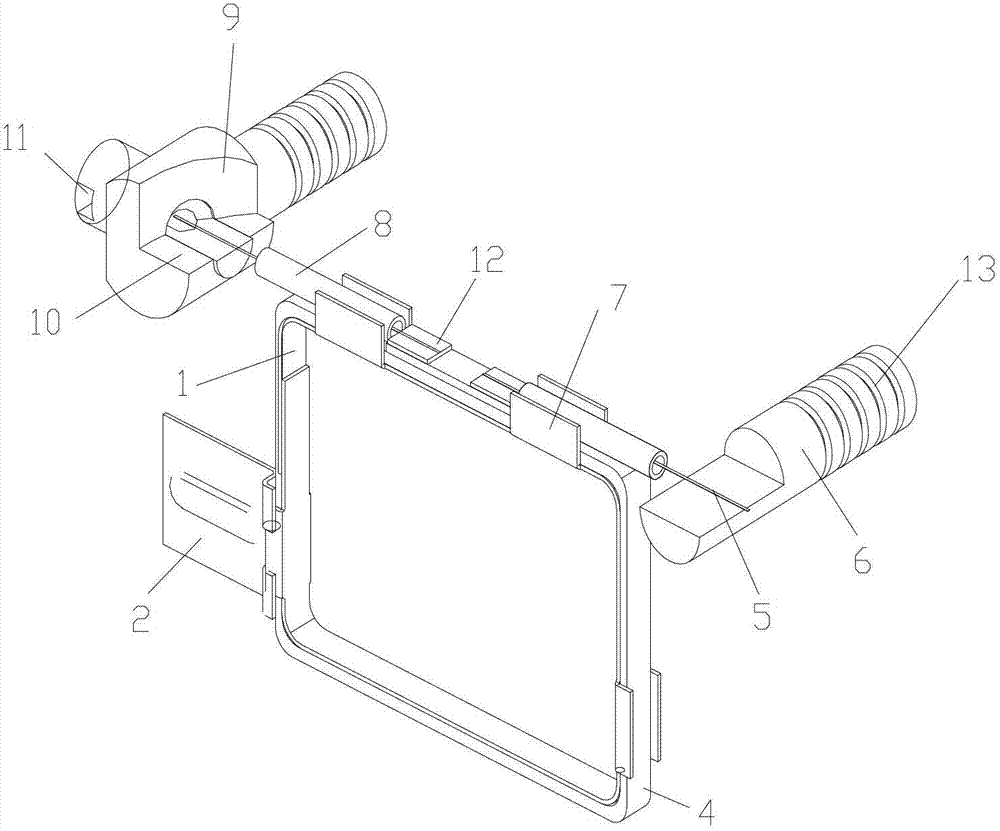

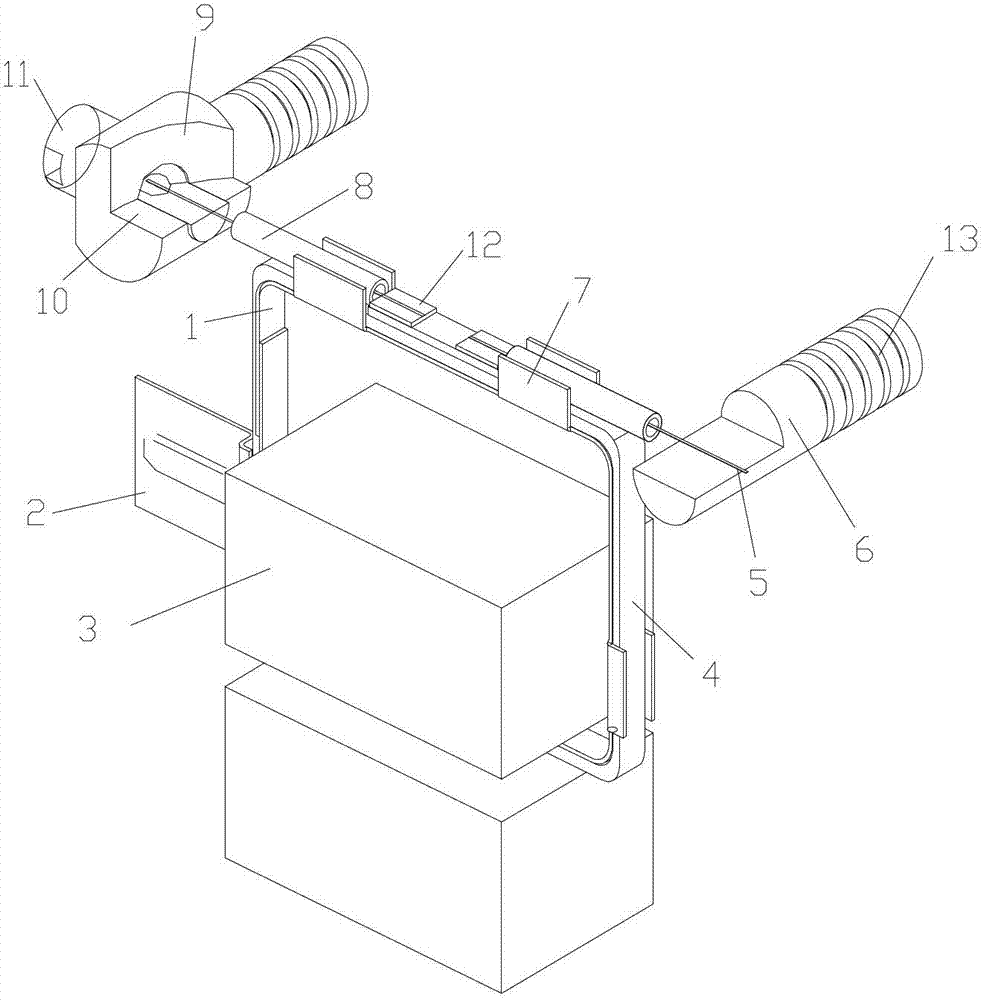

Short fiber post-processing string-up device and short fiber post-processing string-up method

The invention provides a short fiber post-processing string-up device and a short fiber post-processing string-up method. The short fiber post-processing string-up device comprises a creel, a yarn guide, an oil bath and a first drawing machine and is characterized in that a braided rope with treelike branches is horizontally laid on the upper surface of the yarn guide, a tail branch of the braided rope is wound on a guide roller, used for winding yarns, of the yarn guide, a secondary tail branch of the braided rope is arranged in the oil bath in a forked manner, and the end of the braided rope is wound a drawing roller, used for drawing the yarns, of the first drawing machine. The short fiber post-processing string-up device and the short fiber post-processing string-up method have the advantages that when the device simple in structure is used, the braided rope is divaricated into a plurality of treelike branches corresponding to number of strands according to needs, the branches are connected with ends of the strands, and keeping drawing under a certain tension can be realized by demanding of one operator pulling the end of the rope and another operator helping to spread yarn sheets, so that manpower is greatly reduced, and waste of raw materials is avoided.

Owner:FUJIAN JINLUN FIBER SHAREHOLDING CO LTD

Preparation method of ultra-light high-strength conductive cable material

InactiveCN109487311AImprove permeabilityEffective blockadeApparatus for manufacturing conducting/semi-conducting layersPorosityFiber

The invention provides a preparation method of an ultra-light high-strength conductive cable material, and relates to the technical field of production of conductive cable materials. The method comprises the following steps of preparation of an electroplating solution, carbon fiber pretreatment, carbon fiber electroplating and carbon fiber post treatment. The defects in the prior art are overcome,the permeation characteristics, adhesion and reliability of the electroplating solution on carbon fibers are effectively enhanced, the conductivity and thermal conductivity of the carbon fibers are effectively improved, the porosity of the carbon fibers is reduced, the oxidation resistance and corrosion resistance of a copper plated layer are effectively improved, no complex sputtering equipmentis needed for preparation bottom copper, one-time electroplating is carried out, and the cost is reduced.

Owner:HUAIBEI HUABO MACHINERY MFG

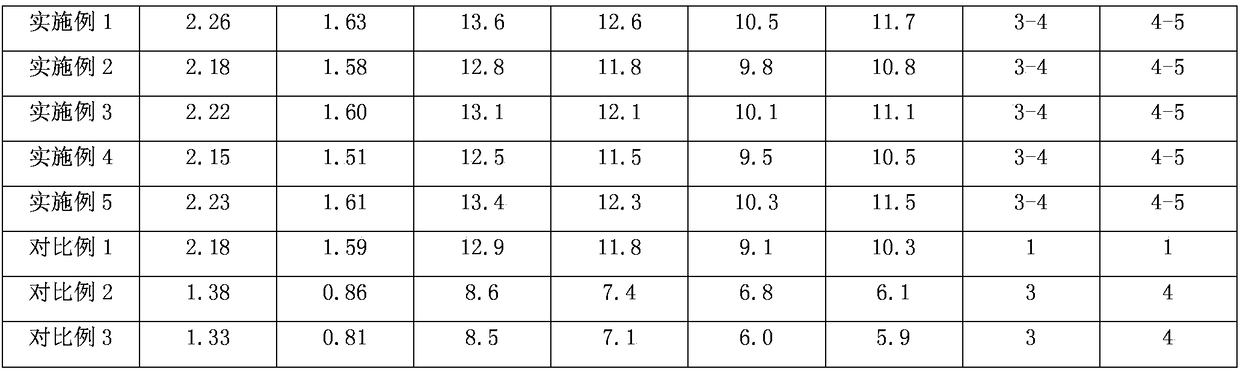

Preparation method of stock solution colored porous regenerated fibers

InactiveCN109505019AAvoid damageUniform and stable colorArtificial filaments from cellulose solutionsCellulose/protein filament chemical after-treatmentPolymer scienceCellulose fiber

The invention belongs to the technical field of preparation of regenerated fibers and in particular relates to a preparation method of stock solution colored porous regenerated fibers. The preparationmethod comprises the following steps: 1) preparing a spinning stock solution; 2) preparing color paste; 3) doing preparation before spinning; 4) molding fibers; 5) carrying out post-treatment on thefibers. According to the preparation method of the stock solution colored porous regenerated fibers provided by the invention, prepared pigment color paste is added into a cellulose spinning solutionand is uniformly stirred; then colored porous regenerated cellulose fibers are prepared through wet-process spinning and fiber post-treatment; damages, caused by dyeing of a dyestuff, to the fibers are solved through the fibers prepared by the preparation method; the utilization rate of a pigment is improved, and the washing fastness and the color fastness to sunlight of the colored fibers are greatly improved; the fibers have good solvent resistance and migration resistance and meet the downstream utilization requirements of cellulose fiber products; the preparation method has the advantagesof simple process, environment friendliness and no pollution, easiness for operation, low energy consumption and easiness for controlling large-scale production.

Owner:WUHE JIANGSU COMPOSITE MATERIALS CO LTD

Collagen-compounding baodao sueded microfiber leather and preparation process thereof

The invention discloses a preparation process of collagen-compounding baodao sueded microfiber leather, and the preparation process comprises the following steps: superfine fiber is prepared by treatment of raw materials before spinning, blending yarn spinning and fiber post-spinning, a non woven fabric is prepared by a non-weaving process from the superfine fiber, and the collagen-compounding baodao sueded microfiber leather is prepared by a base cloth processing process from the non woven fabric. The invention also discloses the collagen-compounding baodao sueded microfiber leather prepared by the process. The collagen-compounding baodao sueded microfiber leather can combine the advantages of both a super fiber material and a leather material, can further meet the anti-aging and anti-wrinkle personalized needs, meanwhile reduction of the cost and shortening of the process time, the prepared finished product has dense structure, soft hand feeling, excellent mechanical properties and other physical properties.

Owner:泉州众信超纤科技股份有限公司

Aqueous baodao sueded microfiber leather and preparation process thereof

The invention discloses a preparation process of aqueous baodao sueded microfiber leather, and the preparation process comprises the following steps: aqueous baodao fiber is prepared by treatment of raw materials before spinning, blending yarn spinning and fiber post-spinning, a non woven fabric is prepared by a non-weaving process from the aqueous baodao fiber, and the aqueous baodao sueded microfiber leather is prepared by a base cloth processing process from the non woven fabric. The invention also discloses the aqueous baodao sueded microfiber leather prepared by the process. The aqueous baodao sueded microfiber leather can combine the advantages of both a super fiber material and a leather material, and adopts waterborne polyurethane to further meet the environmental protection needs, meanwhile reduction of the cost and shortening of the process time, the prepared finished product has dense structure, soft hand feeling, excellent mechanical properties and other physical properties.

Owner:泉州众信超纤科技股份有限公司

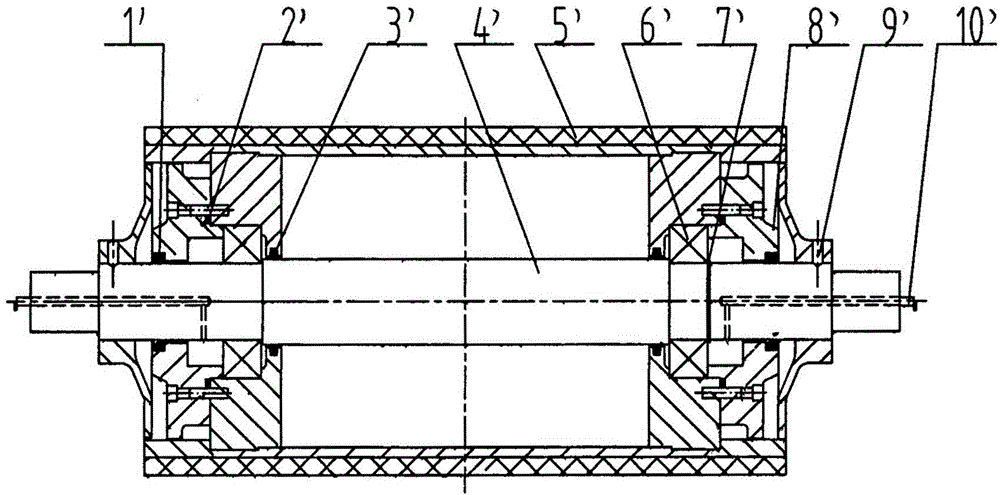

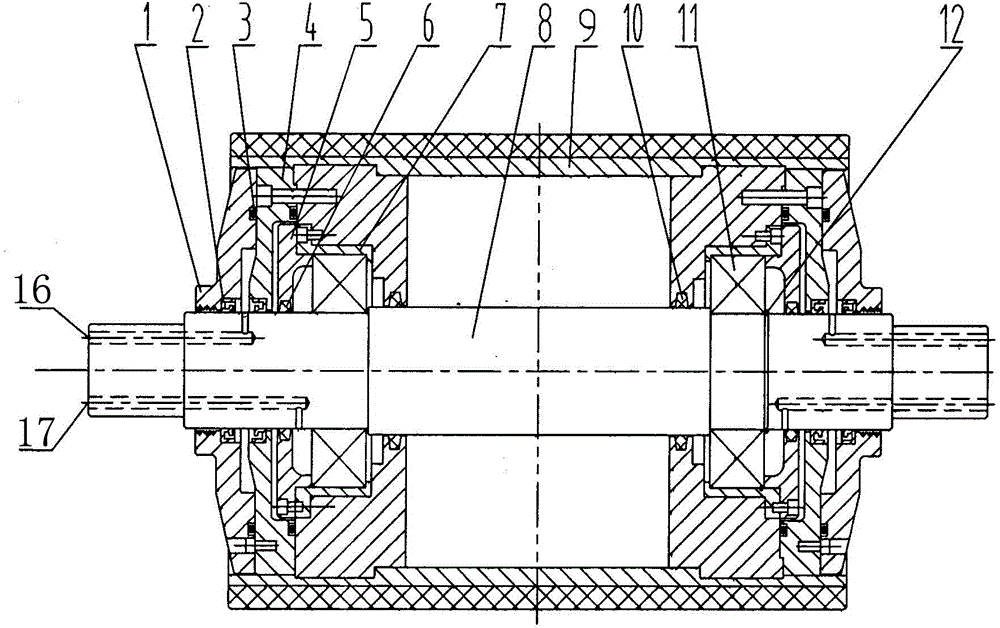

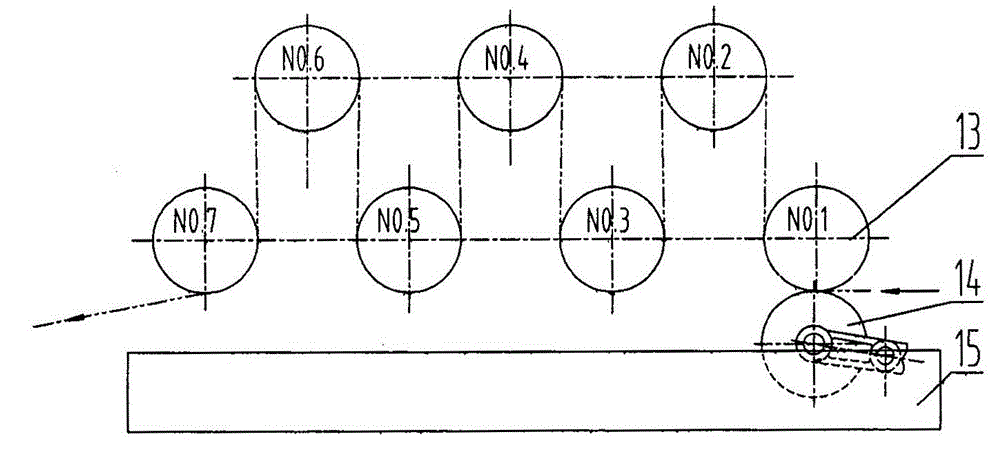

Rubber compression roller device suitable for draw machine of polyester staple fiber post-treatment equipment

ActiveCN104806642AImprove the lubrication effectEasy to disassembleBearing unit rigid supportPolyesterEngineering

The invention discloses a rubber compression roller device suitable for a draw machine of polyester staple fiber post-treatment equipment. The rubber compression roller device comprises a compression roller shaft combined with a rubber compression roller through bearings, wherein bearing seats used for mounting the bearings are fixedly mounted in shaft holes in two ends of the rubber compression roller through connecting pieces; the bearings are sealed in the bearing seats through bearing end covers; a sealing felt ring is mounted in each of an annular groove in the inner cylindrical surface of the bearing end cover matched with the compression roller shaft and an annular groove in the inner cylindrical surface of a rubber compression roller plug; a pressure cover is mounted on the outer end surface of the rubber compression roller plug through a connecting piece; an O-shaped seal ring is mounted between the seal fit surfaces of the pressure cover and the rubber compression roller plug; a skeleton seal ring is embedded into an annular groove in the inner cylindrical surface, matched with the compression roller shaft, of the pressure cover; a water throwing disc is mounted on the outer side of the pressure cover through a connecting piece; an O-shaped seal ring is mounted between the seal fit surfaces of the water throwing disc and the pressure cover; a skeleton seal ring is embedded into an annular groove in the inner cylindrical surface, matched with the compression roller shaft, of the water throwing disc.

Owner:CHTC HEAVY IND +1

Method for manufacturing elastic porcelain super-inlay of fiber post

InactiveCN110269702AImprove aestheticsImprove stabilityTeeth fillingTeeth cappingNatural toothTreatment design

The invention provides a method for manufacturing an elastic porcelain super-inlay of a fiber post. The method comprises the following specific steps of: (1) carrying out digital scanning impression on a tooth cavity type prepared by cavity type preparation and post channel preparation; (2) directly inserting a fiber post into a prepared post channel, and carrying out digital scanning impression on the tooth cavity type inserted into the fiber post again; (3) according to the digital scanning impression in the step (1) and the step (2), designing an elastic porcelain super-inlay model containing pile holes through CAD and CAM technology treatment, and performing trimming and processing to obtain the elastic porcelain super-inlay with the post holes; and (4) passing the fiber post through a post hole of the elastic porcelain super-inlay, fixing the fiber post on the post hole through adhesive resin, and finally performing polishing. The super-inlay prepared by the method has good beauty, high compressive strength and good ductility, can reduce the abrasion to natural teeth of the jaw, ensures good edge adhesion through digital scanning impression and CAD and CAM manufacturing, has lower price than zirconium dioxide, and has a saving effect.

Owner:JINAN UNIVERSITY

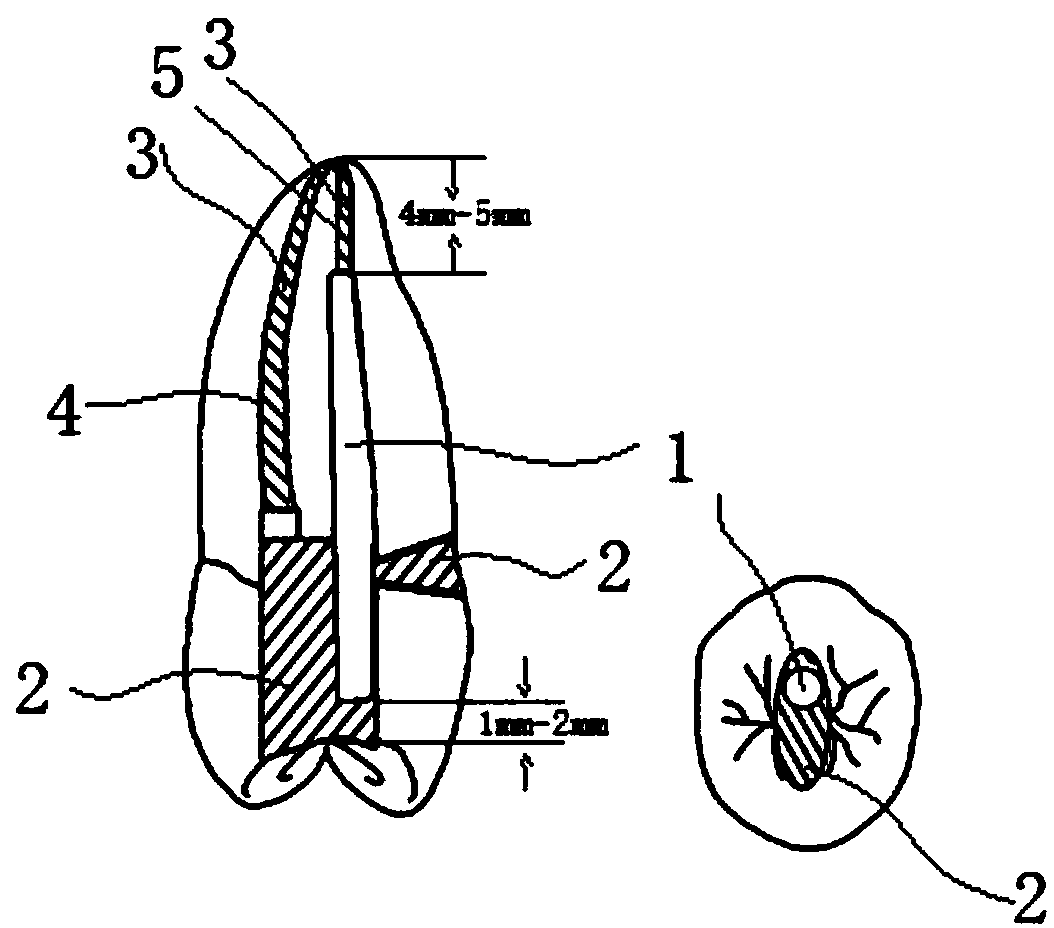

Maxillary premolar severe wedge-shaped defect fiber post restoration and production method thereof

The invention discloses a mandibular premolar severe wedge-shaped defect fiber post restoration. The mandibular premolar severe wedge-shaped defect fiber post restoration comprises a single fiber postand a wedge-shaped composite resin filling, and the single fiber post is a cylinder with the tail end diameter being 0.7-0.8 mm and the occlusion square diameter being 1.3-1.6 mm; and the height of the single fiber post is 6.0-7.5 mm less than that of a tooth length. The depth from the tip end to the bottom end of the wedge-shaped composite resin filling is 1 / 2 to 2 / 3 of the buccolingual diameterof a dental cervical part, the width of the wedge-shaped composite resin filling is from the mesial proximal surface to the distal mandibular premolar of the mandibular premolar tooth, the thicknessis 3.0-5.0 mm, and the wedge-shaped composite resin filling encircles occlusal 1 / 3 to middle 1 / 3 junction of the singe fiber post. The single fiber post of the restoration is positioned in a buccal root canal, and the fiber post is compounded with the composite resin by using the connection and auxiliary retention effects of the fiber post in order to directly complete the restoration without fullcrown.

Owner:西安交通大学口腔医院

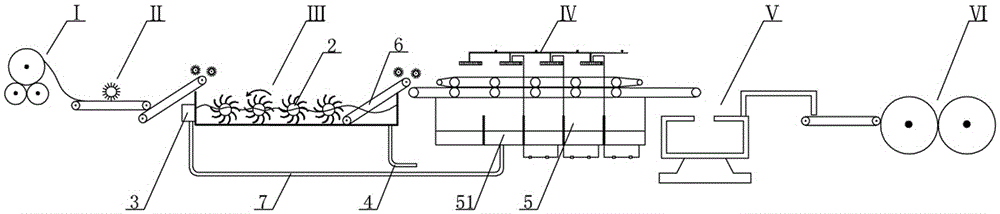

Continuous loose fiber post-processing technology

InactiveCN105088586AFully contactedShorten the lengthSucessive textile treatmentsFibre cleaning/openingFiberProcess equipment

The invention discloses a continuous loose fiber post-processing technology. The continuous loose fiber post-processing technology sequentially comprises the steps of opening, steeping type washing, spraying squeezing type washing, dewatering, drying and the like. The continuous loose fiber post-processing technology has the advantages of being small in processing equipment occupied area, low in production cost and the like.

Owner:SHAOXING GUOZHOU HLDG GRP CO LTD

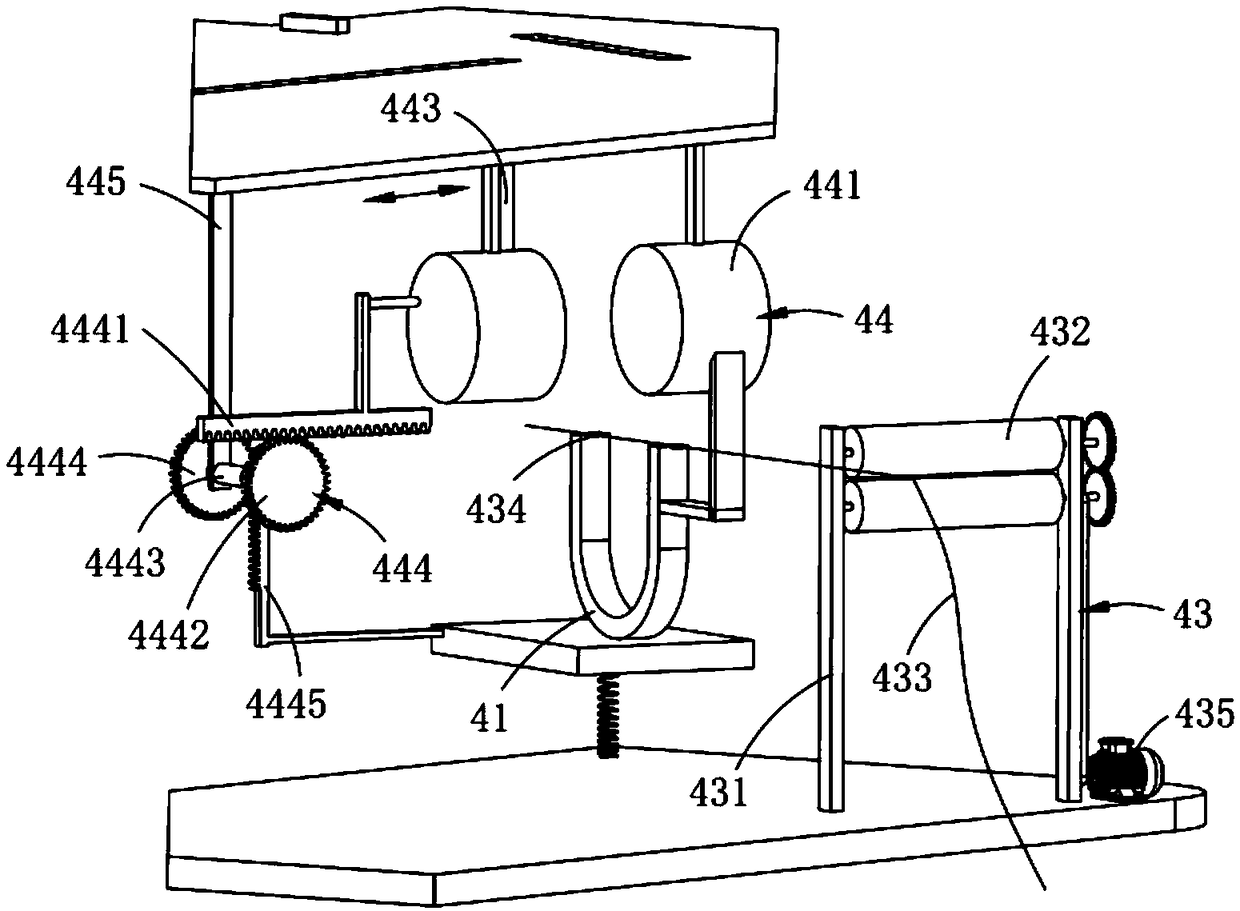

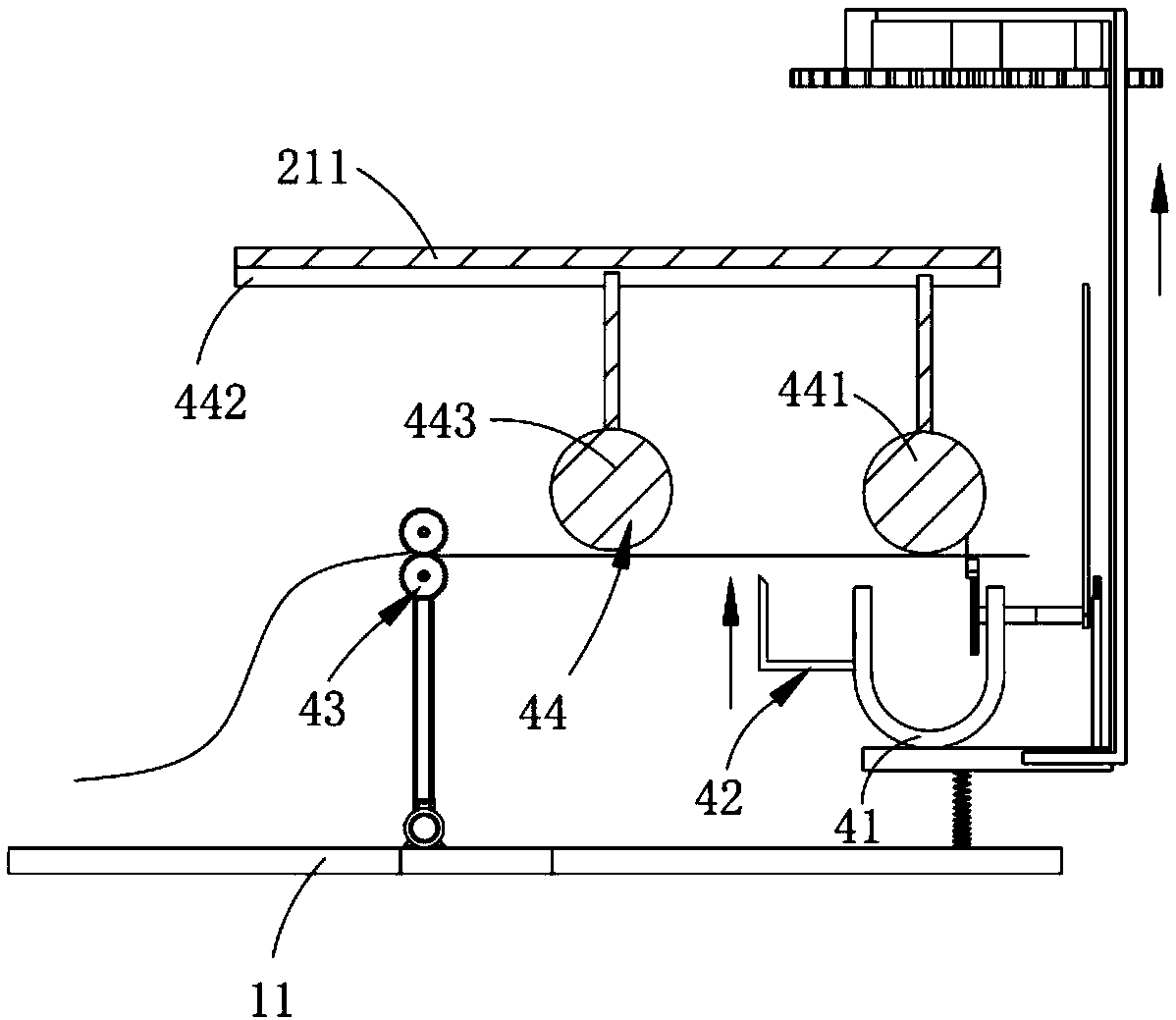

Short fiber post-treatment equipment

InactiveCN108754675ASave materialHigh degree of automationSevering to form staple fibresBinding material applicationCompression moldingFiber bundle

The invention relates to short fiber post-treatment equipment which comprises a grouping mechanism, a collecting mechanism, a bundling mechanism and a compression molding mechanism, wherein the grouping mechanism comprises a rack, a conveying component a and a conveying component b; the collecting mechanism comprises a fixed cutting component and a push component; the push component is arranged ona cutting seat of the fixed cutting component in a sliding manner and slides along a width direction of the rack; the bundling mechanism is arranged at the tail end of the cutting seat and comprisesa lifting component and a torsion component; the lifting component is positioned below the cutting seat and is in running fit with the push component; the torsion component is fixedly connected with the lifting component and positioned above the cutting seat; the compression molding mechanism comprises a U-shaped seat, a cutting component, a delivery component and a molding component; the U-shapedseat is arranged on the lifting component; the cutting component is arranged on the U-shaped seat; the delivery component is positioned on one side of the lifting component; the molding component ispositioned above the lifting component and below the cutting seat; the molding component is arranged on the lower surface of the cutting seat in a sliding manner. According to the short fiber post-treatment equipment disclosed by the invention, the technical problem short fibers mixed in fiber bundles are accurately collected in the carding operation is solved.

Owner:CHANGXING DEHONG MACHINERY CO LTD

A kind of preparation method of quartz fiber with X-ray anti-radiation agent coating

ActiveCN106316159BUniform X-ray opacity performanceImprove the effect of blocking X-raysGlass making apparatusCooking & bakingYarn

The invention relates to a preparation method of quartz fiber with X-ray radiation prevention agent coating, and belongs to the technical field of quartz fiber production. Surface of quartz fiber filament is treated using the surface treating agent containing radiation prevention agent, then quartz fiber filament is coiled to quartz fiber strand by the high speed rotation and traction of the head of drawing mill, and finally, the strand is subjected to baking, degradation, pre-twist and cabling to form the final product of quartz fiber yarn with a coating containing radiation prevention agent. The quartz fiber with a coating containing radiation prevention agent made using such method has the strengths of simple techniques and low cost, and can well combined with epoxy, and can be produced to the fiber post with homogeneous X-ray prevention effect.

Owner:HUBEI FEILIHUA QUARTZ GLASS

High-capacity viscose staple fiber post-treatment production line

InactiveCN103422290BWash fineFine desulfurizationSucessive textile treatmentsLiquid/gas/vapor removalProduction lineSingle process

The invention aims at providing a high-capacity viscose staple fiber post-treatment production line in order to reach the annual yield of 100 thousand tons. The production line comprises a refining system and a drying system. A refiner in the refining system comprises a refining section and an oiling section. The high-capacity viscose staple fiber post-treatment production line is characterized in that the breadth of the refiner of the refining system is 4000mm, the refining section is divided into 13-18 process areas, the oiling section is divided into 2 process areas and the length of a single process area is 2500mm. The viscose staple fiber post-treatment production line comprises the refining system and the drying system, and has the advantages that the production capacity is strong, the operation stability is high, the automation level is high and the product quality is guaranteed.

Owner:YIBIN GRACE +2

Continuous loose fiber post-processing device

ActiveCN105088577AReduce consumptionFully contactedTextile treatment machine arrangementsTextile treatment carriersFiberSmall footprint

The invention discloses a continuous loose fiber post-processing device. The continuous loose fiber post-processing device comprises an uncoiling machine, a steeping type rinse tank, a spraying squeezing type washing machine and a dewatering machine which are arranged in sequence. The continuous loose fiber post-processing device has the advantages of being small in occupied area, low in production cost and the like.

Owner:SHAOXING GUOZHOU HLDG GRP CO LTD

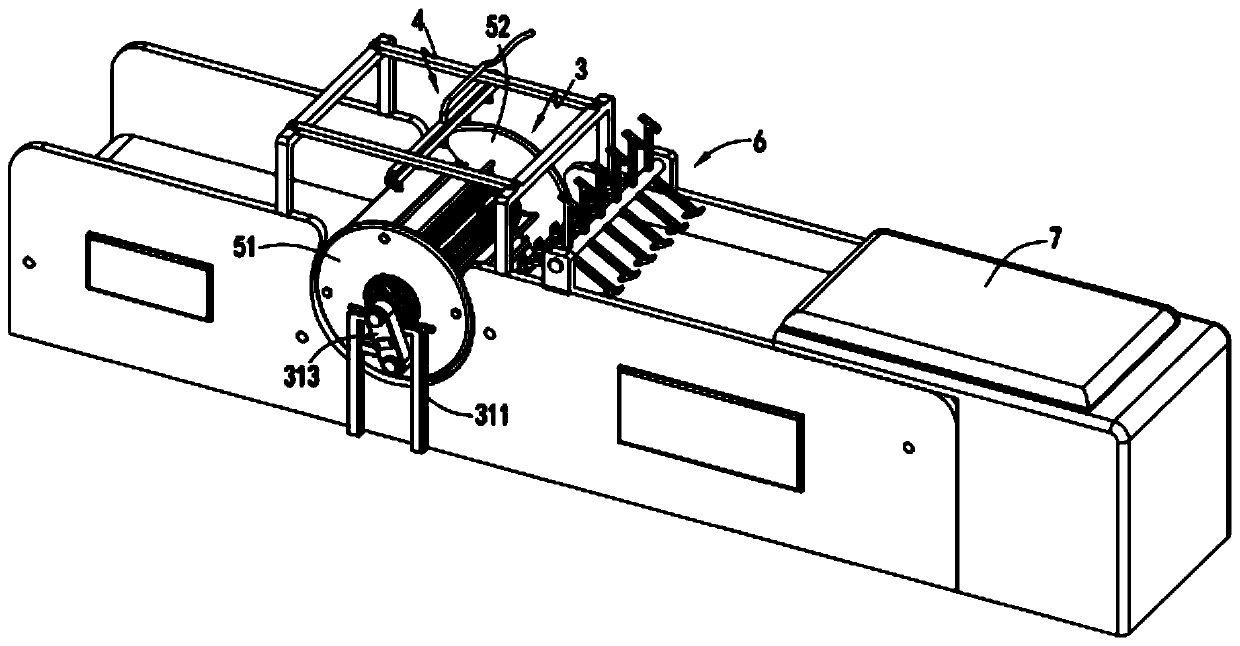

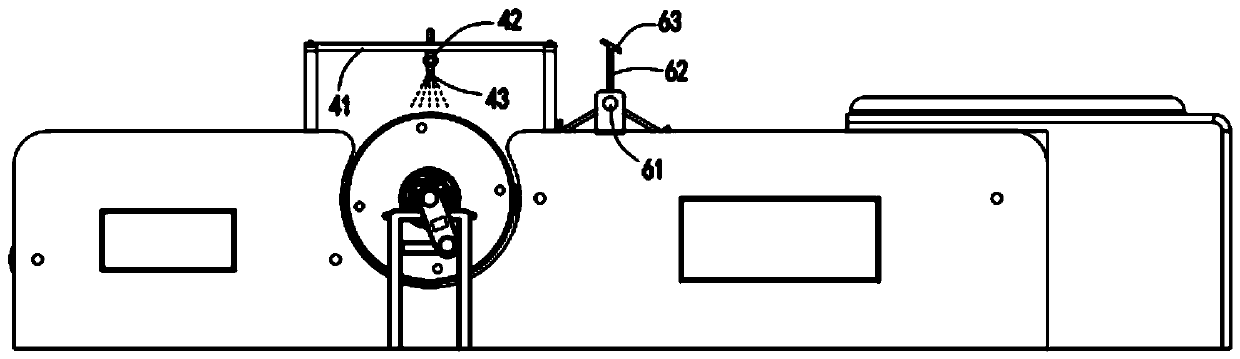

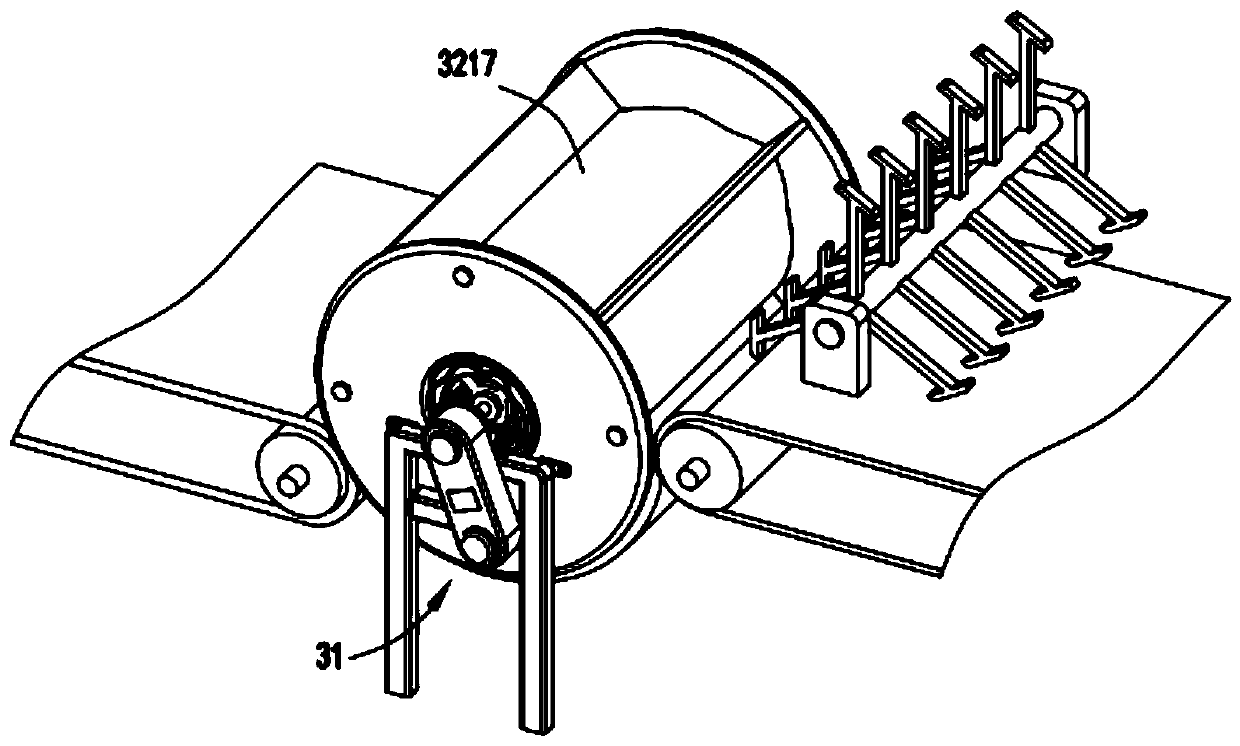

Polyester staple fiber post-processing production equipment and process thereof

InactiveCN110453315AImprove uniformityImprove anti-static effectFibre cleaning/opening machinesTextile treatment by spraying/projectingFiberPolyester

The invention relates to the field of staple fiber production equipment, in particular to polyester staple fiber post-processing production equipment. The equipment comprises a first conveyor belt anda second conveyor belt which are arranged front and rear, a turnover and shaking device is arranged between the first conveyor belt and the second conveyor belt, and a spraying device is arranged above the turnover and shaking device; the turnover and shaking device comprises a rotating mechanism and a shaking mechanism, the shaking mechanism receives staple fibers conveyed by the first conveyorbelt and is driven by the rotating mechanism to support the staple fibers to rotate, the staple fibers are turned over, shaken and scattered by the shaking mechanism in the rotation process, and the spraying device cooperates with the shaking mechanism to spray an anti-static agent to the staple fibers which are continuously turned over and shaken. The invention further provides a corresponding production process. The technical problems are solved that existing anti-static agent spraying modes are poor in spraying uniformity, it cannot be ensured that an anti-static agent is sprayed to staplefibers at the surface layer and the bottom, the staple fibers at the bottom can still generate static electricity in the subsequent treatment process, and the product quality is influenced.

Owner:浙江时代纤维有限公司

Continuous bulk fiber post-processing device

ActiveCN105088575BReduce consumptionFully contactedTextile treatment machine arrangementsTextile treatment carriersFiberSmall footprint

The invention discloses a continuous bulk fiber post-processing device, which comprises an unwinding machine, a soaking type cleaning tank, a rolling type washing machine, a water rolling machine and a dewatering machine arranged in sequence. The continuous bulk fiber post-processing device of the present invention has the advantages of small occupied area, low production cost and the like.

Owner:SHAOXING GUOZHOU HLDG GRP CO LTD

Suspension fiber flexibleness supporting structure

ActiveCN103033637AEasy processing and assemblyImprove reliabilitySpeed/acceleration/shock instrument detailsFiberAccelerometer

The invention provides a suspension fiber flexibleness supporting structure which comprises a swing framework and a force moment coil, wherein the force moment coil is arranged on the swing framework in a winding mode and limited by clamping plates. Suspension fibers are arranged at two sides of the upper end of the swing framework. One end of each suspension fiber is fixedly connected with the force moment coil. The other end of each suspension fiber penetrates an insulating tube and then is respectively welded with a suspension fiber post and an adjustable suspension fiber post to form a whole. The suspension fiber post is connected with a base of an accelerometer in a cementing mode to form a whole. A vortex vane is arranged at one side of the swing framework. The suspension fiber flexibleness supporting structure has the advantages of being easy to process and assemble, high in reliability, low in cost, capable of achieving volume production, good in practicality, easy to popularize and apply and big in practical value.

Owner:SHAANXI BAOCHENG AVIATION INSTR

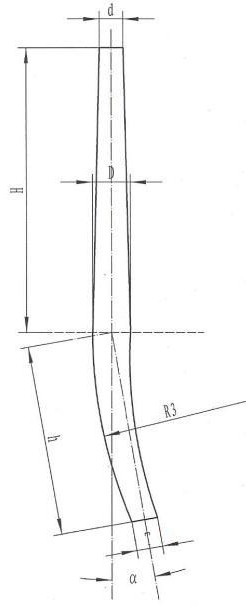

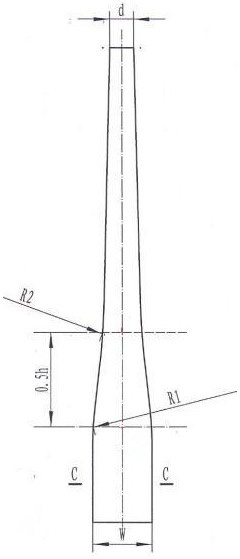

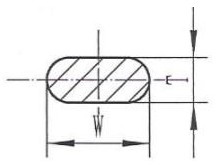

Dentistry bionic radian curve fiber post

The invention relates to a dentistry bionic radian curve fiber post, which solves the problem that vast majority of the existing dentistry fiber posts are straight nails, and have influences on uniform distribution of stress and arrangement and appearance of a crown portion. The fiber post comprises a root inner section and a root outer section, the root inner section is in a shape of a cylindrical table, the root outer section is divided into an upper root outer section and a lower root outer section, the top end of the upper root outer section is connected with the root inner section, and the bottom end of the upper root outer section is connected with the lower root outer section. The cross section of the upper root outer section is in a shape of a kidney, a generatrix of the upper root outer section is composed of two sections of tangential arcs, an upper arc section is tangential with the generatrix of the root inner section, a lower arc section is tangential with the generatrix of the root outer section, and the cross section of the lower root outer section is in a shape of a kidney. The dentistry bionic radian curve fiber post meets requirements of biomechanics, is providedwith root pipe post forms bionically designed according to biological parameters, and solves the problem that application of end product fiber posts is limited when used for repairing front teeth dueto the fact that the end product fiber posts can not be bent.

Owner:ZHEJIANG UNIV +2

Polyester polyol and polyurethane resin for superfine fiber synthetic leather

Owner:XUCHUAN CHEM SUZHOU

Biomass composite emulsifier special for cellulose acetate oil agent

InactiveCN109056318AGood dispersionImproved post-processing performanceVegetal fibresFiberCellulose acetate

The invention discloses a biomass composite emulsifier special for a cellulose acetate oil agent. The biomass composite emulsifier special for the cellulose acetate oil agent is mainly prepared from the following materials in parts by weight: 50 to 60 parts of emulsifier, 6 to 8 parts of sterilizing agent, 3 to 5 parts of stabilizer, 0.5 to 1 part of sulfo-bisphenol, 4 to 6 parts of lanthanum dialkyl dithiocarbamate and 1 to 5 parts of dioctyl sebacate. The formula of the emulsifier is optimized, so that the emulsifier has excellent dispersing property and also has excellent antibacterial andacetate fiber post-processing properties.

Owner:JIANGSU SIXIN SURFACTANT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com