Continuous loose fiber post-processing technology

A loose fiber and post-processing technology, applied in the field of continuous loose fiber post-treatment process, can solve the problems of high production cost, large water and electric power consumption, large floor space, etc., so as to reduce production cost and reduce floor space. , good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below by means of the accompanying drawings and examples.

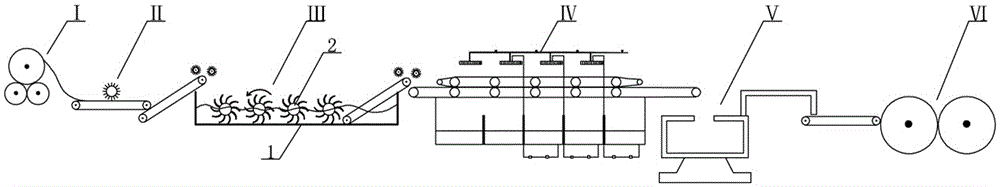

[0016] Such as figure 1 Shown: a continuous bulk fiber post-treatment process, which includes the steps of opening, immersion cleaning, rolling washing, dehydration, drying, etc. The steps are further described below:

[0017] (1) Opening: through the opening machine II, the blanket-like loose fibers unrolled from the unwinding machine I are opened into fluffy loose fibers, and the loose fibers that have been opened are fed into the immersion cleaning tank III middle.

[0018] (2) Immersion cleaning: Soak the loose fibers in the immersion cleaning tank III for immersion cleaning, and transport the cleaned loose fibers to the shower rolling washing machine IV. Among them, the immersion cleaning is completely different from the traditional padding washing or shower washing. The immersion cleaning tank III includes a cleaning tank 1 and a conveying roller 2 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com