Short fiber post-processing string-up device and short fiber post-processing string-up method

The invention relates to a spinning device and a technology for short fiber, which is applied in the field of short fiber post-processing spinning devices, and can solve the problems of increasing the operating strength and difficulty, excessive waste silk, and stiffness of the silk sheet, and achieves the reduction of manpower, the simple structure, and the avoidance of waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

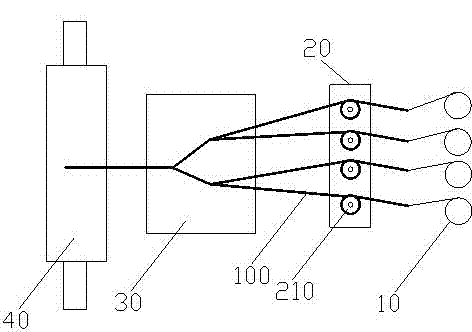

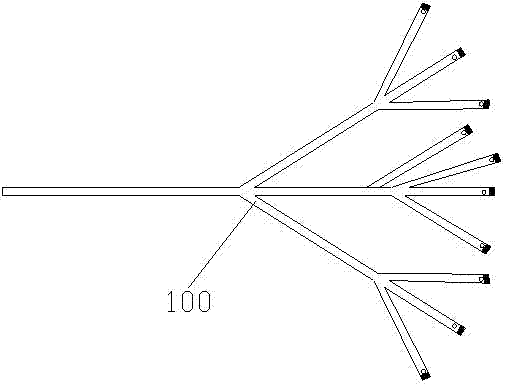

[0019] Such as figure 1 As shown, the spinning-in device for the post-processing of short fibers includes a cluster frame 10 for placing the raw yarn along the production process, a wire guide machine 20, an oil immersion tank 30 arranged on the rear side of the wire guide machine 20, and a first drafting machine , the braided rope 100 with tree-like branches is flatly laid on the upper surface of the wire guide machine 20, and the last branch of the braided rope is wound on the wire roller 210 of the wire guide machine for winding silk threads. The braided rope The last stage is bifurcated and arranged in the oil immersion tank 30, and the end of the braided rope is wound on the first drafting machine pulling roller 40 for pulling the wire.

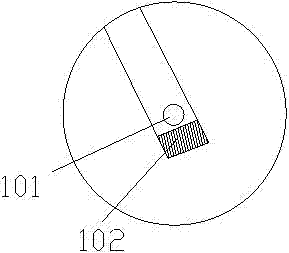

[0020] The forked end of the last stage of the braided rope is provided with an opening 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com