Technique for preparing lotus fiber by joint process

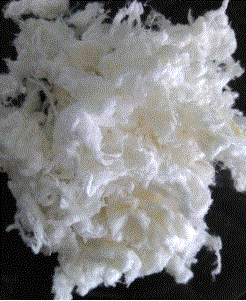

A technology of lotus fiber and combination method, applied in the field of new natural fiber materials, can solve the problems of rough lotus fiber, unfavorable production efficiency, low production efficiency, etc., and achieve the effects of promoting fiber extraction, shortening production cycle, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

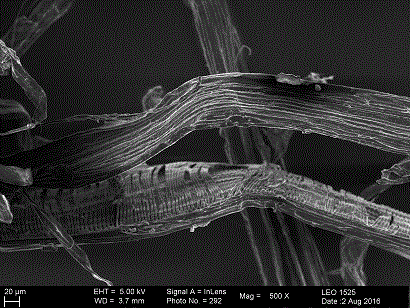

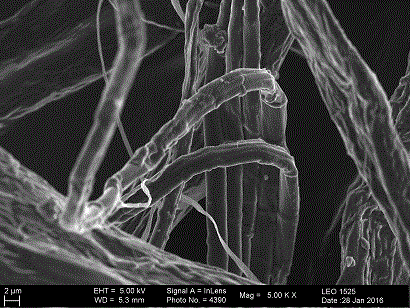

Image

Examples

Embodiment 1

[0052] Weigh 20g of dried lotus stalks and organize them into 5cm long segments. Prepare 1L of sodium hydroxide solution with a concentration of 20g / L, add 3g of sodium silicate and 2g of sodium tripolyphosphate. In an oil bath at 90°C for 4h. After the reaction was completed, the sample was taken out, washed 3 times with distilled water, and then soaked in distilled water for 3 h. Take out the sample, wash away the tissue between the lotus stalk fiber and the epidermis through mechanical extrusion, rinse with a 2mm sieve to remove impurities such as sediment, repeat this operation until the filtrate is neutral, and the sediment in the filtrate basically disappears. ℃ drying 24h. Weigh the sample, add 12g of sodium chlorite and 6mL of glacial acetic acid per gram of sample, add distilled water, seal the container, and place it in an oil bath at 70°C for 3 hours. Wash the sample with distilled water until neutral, crush the epidermal tissue by mechanical extrusion, rinse wit...

Embodiment 2

[0056] Weigh 20g of dried lotus stalks and organize them into 5cm long segments. Prepare 1L of sodium hydroxide solution with a concentration of 20g / L, add 3g of sodium silicate and 2g of sodium tripolyphosphate. Set the ultrasonic power to 140W, and ultrasonicate at 70°C for 30min. After the reaction was completed, the sample was taken out, washed 3 times with distilled water, and then soaked in distilled water for 3 h. Take out the sample, wash away the tissue between the lotus stem fiber and the epidermis through mechanical extrusion, rinse with a 2mm sieve to remove impurities such as sediment, repeat this operation until the filtrate is neutral, and the sediment in the filtrate basically disappears. ℃ drying 24h. Weigh the sample, add 12g of sodium chlorite and 6mL of glacial acetic acid per gram of the sample, add distilled water, seal the container, set the ultrasonic power to 140W, and heat in a water bath at 60°C for 20 minutes. Wash the sample with distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com