Polyester staple fiber post-processing production equipment and process thereof

A technology of polyester staple fiber and production equipment, which is applied in the field of polyester staple fiber post-processing production equipment and its technology, can solve the problems of inability to guarantee the spraying of short fibers, affect product quality, generate static electricity, etc., and achieve a simple and ingenious structure and low cost. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

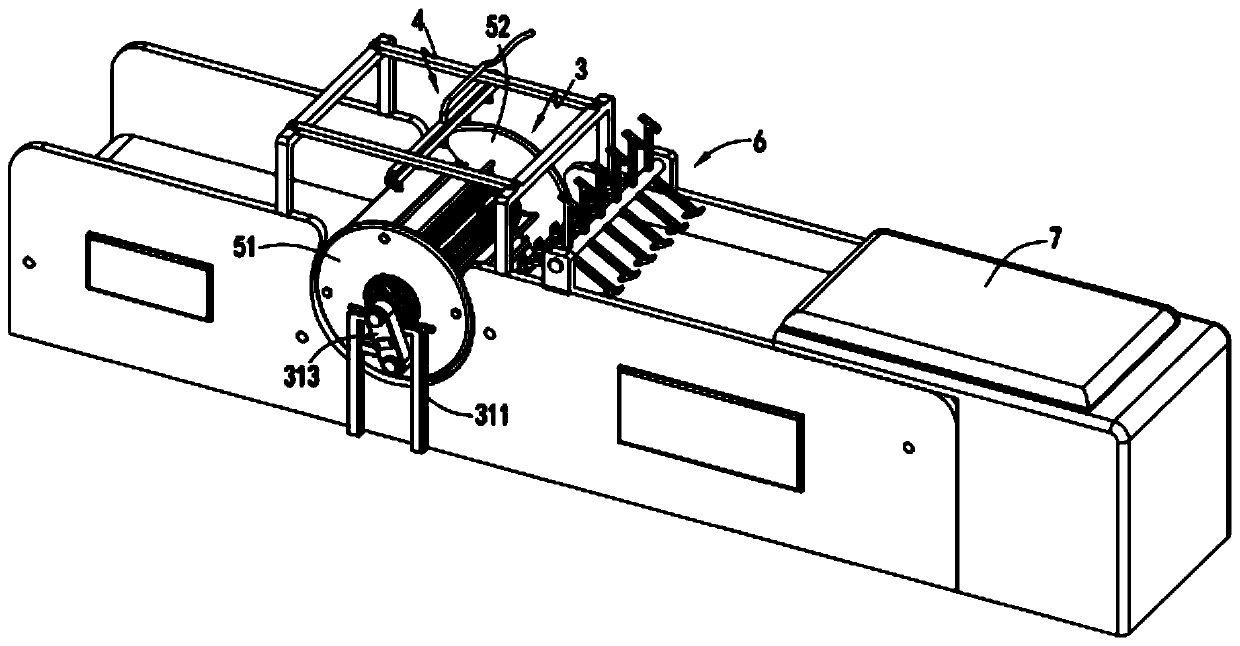

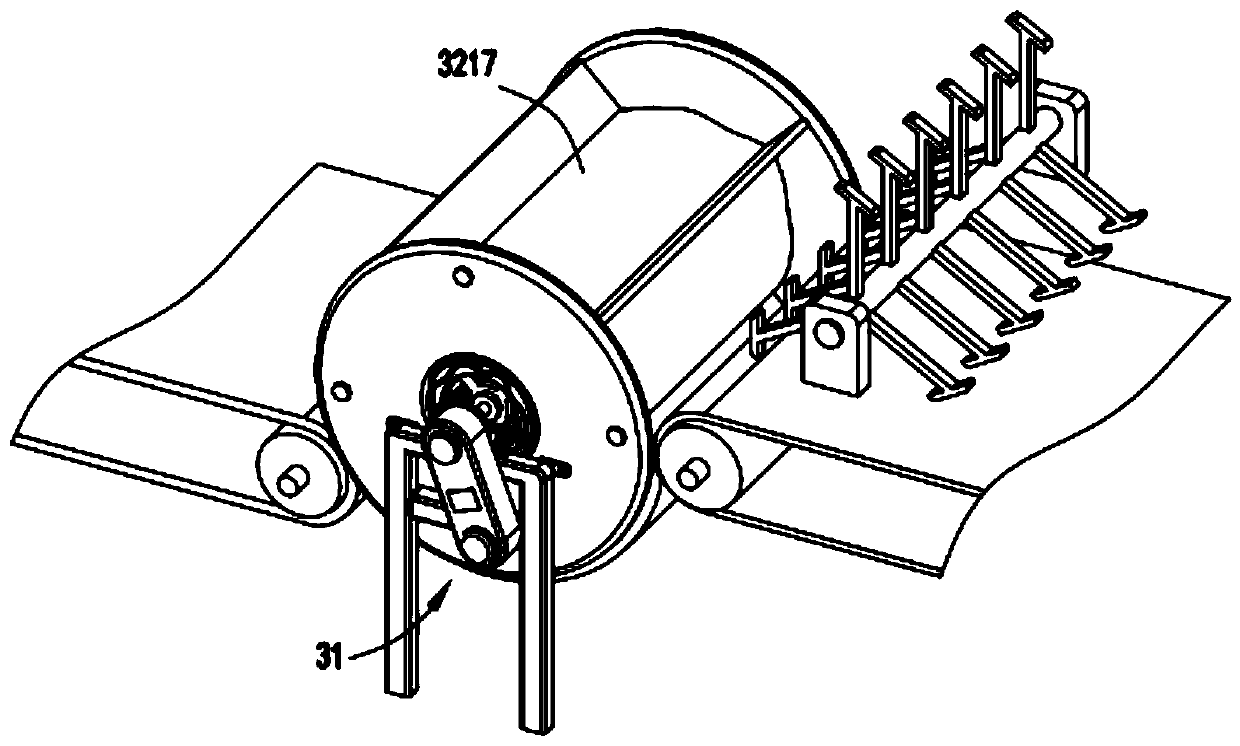

[0049] Such as Figure 1 to Figure 9 As shown, a polyester staple fiber post-processing production equipment includes a first conveyor belt 1 and a second conveyor belt 2 arranged front and back, and a shaking device 3 is arranged between the first conveyor belt 1 and the second conveyor belt 2 , the top of the shaking device 3 is provided with a spraying device 4, the shaking device 3 includes a rotating mechanism 31 and a shaking mechanism 32, and the shaking mechanism 32 accepts the short fibers transported by the first convey...

Embodiment 2

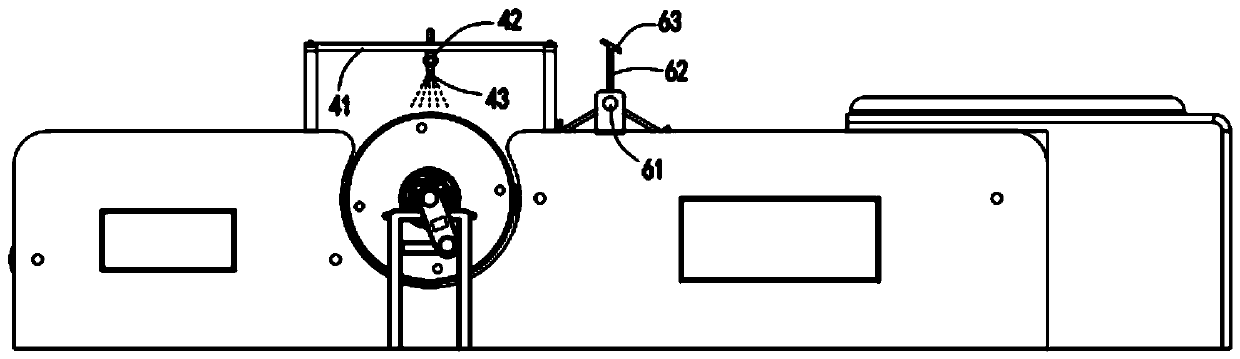

[0064] Such as image 3 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that: further, a shifting mechanism 6 is provided at the tail end of the first conveyor belt 1, and the shifting mechanism 6 includes a rotating shaft 61 that rotates in the clockwise direction and is arranged in an array along the length direction of the rotating shaft 61. There are several shifting rods 62, the ends of the shifting rods 62 are provided with inclined shifting feet 63.

[0065] In this embodiment, the short fibers before entering the turning device are preliminarily dispersed by setting the material shifting mechanism 6. The combination of the two makes the effect of the subsequent turning device better when the short f...

Embodiment 3

[0067] Such as Figure 10 as shown,

[0068] A post-treatment production process for polyester staple fibers, comprising the following production steps:

[0069] Step 1, the transmission and drying process, the short fibers are transported through the oven under the drive of the first transmission belt 1 for drying treatment;

[0070] Step 2, the feeding process, the dried short fibers are transferred to the feeding station, and the feeding mechanism 6 located at the feeding station distributes the short fibers in the transmission process backward;

[0071] Step 3, the shaking process, the short fiber distributed in the step 2 enters the shaking station, and the rotating mechanism 31 located at the turning station drives the short fiber to rotate, and the shaking mechanism passes through the shaking mechanism during the rotation. 32 shake short fibers;

[0072] Step 4, spraying process, the staple fibers in the step 3 are in the process of shaking, the spraying device 4 abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com