A kind of preparation method of quartz fiber with X-ray anti-radiation agent coating

A technology of quartz fiber and quartz glass fiber, which is applied in the field of preparation of quartz fiber, to achieve the effect of improving the effect, reducing the difficulty of processing, and uniform X-ray resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

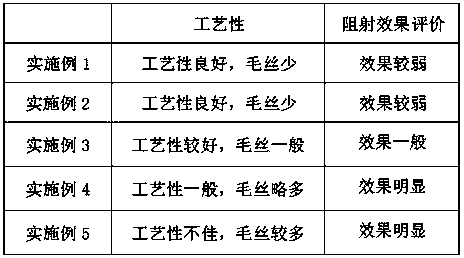

Examples

Embodiment 1

[0036] Take each raw material by the following parts by weight:

[0037] Barium sulfate 40, silicon dioxide 30, aluminum oxide 5, strontium oxide 0.5;

[0038] Mix barium sulfate, silicon dioxide, aluminum oxide, and strontium oxide evenly to prepare an X-ray blocking agent for subsequent use;

[0039] Take each raw material by the following weight percentages:

[0040] Fatty alcohol polyoxyethylene ether 0.5 Vinyl silane coupling agent 0.3

[0041] Water-soluble epoxy resin 0.5 Glacial acetic acid 0.02

[0042] X-ray blocking agent 1 The balance is deionized water

[0043] Add a quarter of the total amount of deionized water into the preparation kettle, then add glacial acetic acid, stir evenly for 3 to 5 minutes, make the pH value 2 to 3, then slowly add vinyl silane coupling agent and continue stirring for 50 Minutes, until the surface of the solution becomes clear and oil-free, the speed should not be too fast during the stirring process to avoid bringing air bubbles. ...

Embodiment 2

[0051] Take each raw material by the following parts by weight:

[0052] Barium sulfate 60, silicon dioxide 40, aluminum oxide 10, strontium oxide 1;

[0053] Mix barium sulfate, silicon dioxide, aluminum oxide, and strontium oxide evenly to prepare an X-ray blocking agent for subsequent use;

[0054] Take each raw material by the following weight percentages:

[0055] Fatty alcohol polyoxyethylene ether 8 Aminosilane coupling agent 1.0

[0056] Water-soluble epoxy resin 10 Formic acid 2

[0057] X-ray blocking agent 5 The balance is deionized water

[0058] Add a quarter of the total amount of deionized water into the preparation kettle, then add glacial acetic acid, stir evenly for 3 to 5 minutes, make the pH value 2 to 3, then slowly add vinyl silane coupling agent and continue stirring for 50 Minutes, until the surface of the solution becomes clear and oil-free, the speed should not be too fast during the stirring process to avoid bringing air bubbles.

[0059] Dilute...

Embodiment 3

[0066] Take each raw material by the following parts by weight:

[0067] Barium sulfate 50, silicon dioxide 35, aluminum oxide 8, strontium oxide 0.7;

[0068] Mix barium sulfate, silicon dioxide, aluminum oxide, and strontium oxide evenly to prepare an X-ray blocking agent for subsequent use;

[0069] Take each raw material by the following weight percentages:

[0070] Fatty alcohol polyoxyethylene ether 5 Epoxy silane coupling agent 0.8

[0071] Water-soluble epoxy resin 7 Glacial acetic acid 1

[0072] X-ray blocking agent 3 The balance is deionized water

[0073] Add a quarter of the total amount of deionized water into the preparation kettle, then add glacial acetic acid, stir evenly for 3 to 5 minutes, make the pH value 2 to 3, then slowly add vinyl silane coupling agent and continue stirring for 50 Minutes, until the surface of the solution becomes clear and oil-free, the speed should not be too fast during the stirring process to avoid bringing air bubbles.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com