Preparation method of quartz fiber with X-ray radiation prevention agent coating

A technology of quartz fiber and quartz glass fiber is applied in the field of preparation of quartz fiber to achieve uniform X-ray blocking performance, improve the effect, and reduce the processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

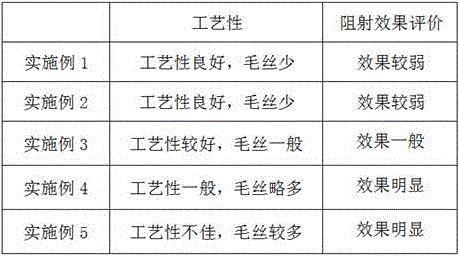

Examples

Embodiment 1

[0036] Take each raw material by the following parts by weight:

[0037] Barium sulfate 40, silicon dioxide 30, aluminum oxide 5, strontium oxide 0.5;

[0038] Mix barium sulfate, silicon dioxide, aluminum oxide, and strontium oxide evenly to prepare an X-ray blocking agent for subsequent use;

[0039] Take each raw material by the following weight percentages:

[0040] Fatty alcohol polyoxyethylene ether 0.5 Vinyl silane coupling agent 0.3

[0041] Water-soluble epoxy resin 0.5 Glacial acetic acid 0.02

[0042] X-ray blocking agent 1 The balance is deionized water

[0043] Add a quarter of the total amount of deionized water into the preparation kettle, then add glacial acetic acid, stir evenly for 3 to 5 minutes, make the pH value 2 to 3, then slowly add vinyl silane coupling agent and continue stirring for 50 Minutes, until the surface of the solution becomes clear and oil-free, the speed should not be too fast during the stirring process to avoid bringing air bubbles. ...

Embodiment 2

[0051] Take each raw material by the following parts by weight:

[0052] Barium sulfate 60, silicon dioxide 40, aluminum oxide 10, strontium oxide 1;

[0053] Mix barium sulfate, silicon dioxide, aluminum oxide, and strontium oxide evenly to prepare an X-ray blocking agent for subsequent use;

[0054] Take each raw material by the following weight percentages:

[0055] Fatty alcohol polyoxyethylene ether 8 aminosilane coupling agent 1.0

[0056] Water-soluble epoxy resin 10 Formic acid 2

[0057] X-ray blocking agent 5 The balance is deionized water

[0058] Add a quarter of the total amount of deionized water into the preparation kettle, then add glacial acetic acid, stir evenly for 3 to 5 minutes, make the pH value 2 to 3, then slowly add vinyl silane coupling agent and continue stirring for 50 Minutes, until the surface of the solution becomes clear and oil-free, the speed should not be too fast during the stirring process to avoid bringing air bubbles.

[0059] Dilute...

Embodiment 3

[0066] Take each raw material by the following parts by weight:

[0067] Barium sulfate 50, silicon dioxide 35, aluminum oxide 8, strontium oxide 0.7;

[0068] Mix barium sulfate, silicon dioxide, aluminum oxide, and strontium oxide evenly to prepare an X-ray blocking agent for subsequent use;

[0069] Take each raw material by the following weight percentages:

[0070] Fatty alcohol polyoxyethylene ether 5 epoxy silane coupling agent 0.8

[0071] Water-soluble epoxy resin7 Glacial acetic acid1

[0072] X-ray blocking agent 3 The balance is deionized water

[0073] Add a quarter of the total amount of deionized water into the preparation kettle, then add glacial acetic acid, stir evenly for 3 to 5 minutes, make the pH value 2 to 3, then slowly add vinyl silane coupling agent and continue stirring for 50 Minutes, until the surface of the solution becomes clear and oil-free, the speed should not be too fast during the stirring process to avoid bringing air bubbles.

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com