Suspension fiber flexibleness supporting structure

A supporting structure and suspension wire technology, which is applied in measuring devices, instruments, speed/acceleration/impact measurement, etc., can solve the problems of difficulty in taking into account the minimum sensitive quantity and low reliability of vibration and impact, and achieve great practical value and good practicability , The effect of simple processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

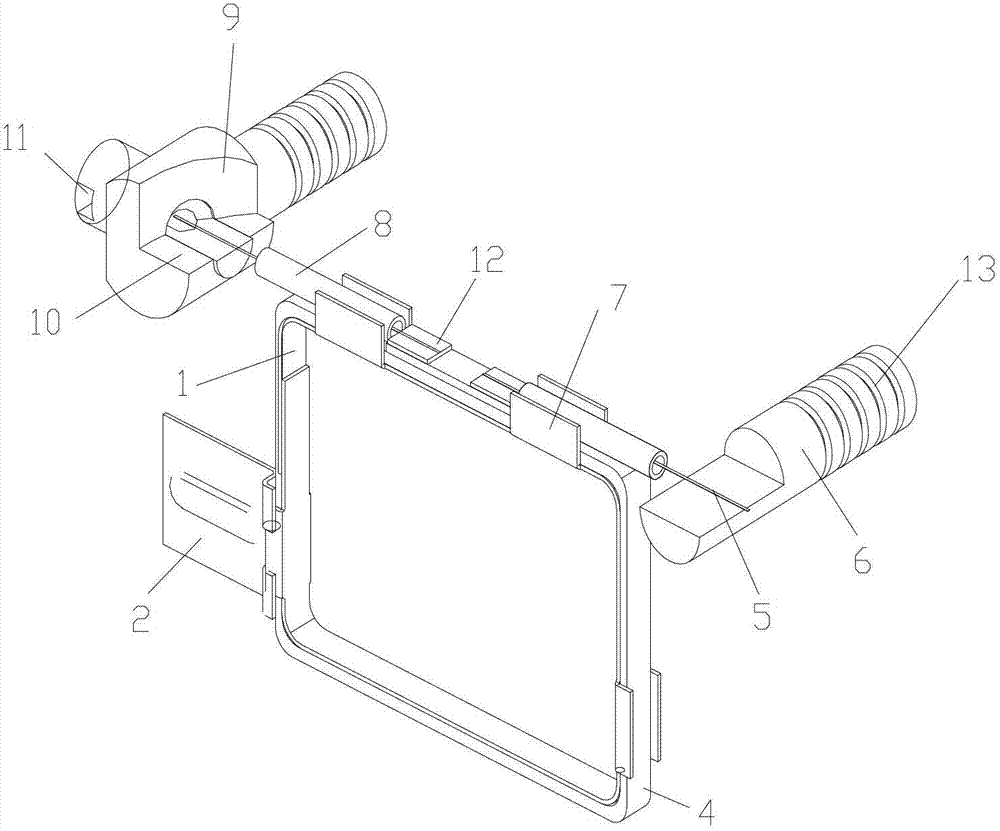

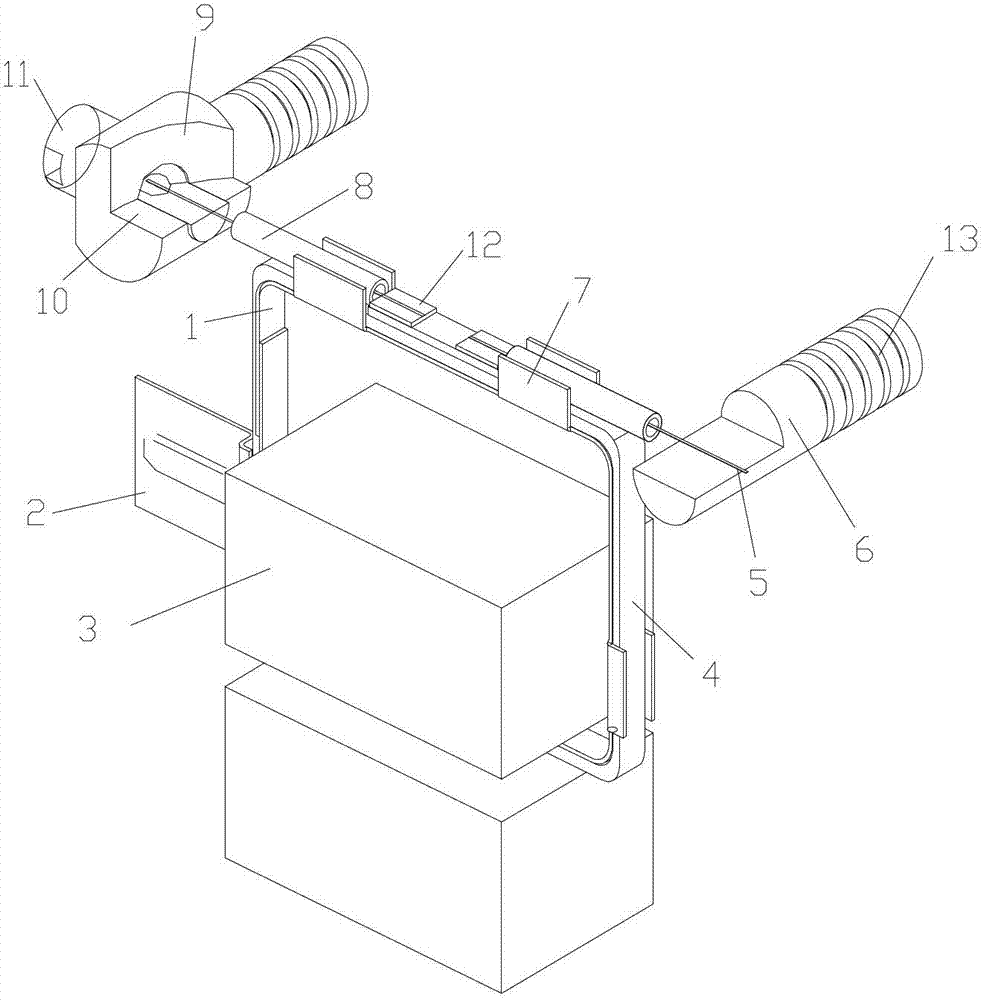

[0013] Attached below Figure 1-2 An embodiment of the present invention is described.

[0014] A suspension wire flexible support structure, which has a pendulum frame 1 and a moment coil 4, the torque coil 4 is wound on the pendulum frame 1 and bound by clamps 7, and both sides of the upper end of the pendulum frame 1 are provided with suspension wires 5 One end of the suspension wire 5 is fixedly connected to the torque coil 4, and the other end of the suspension wire 5 passes through the insulating tube 8 and is respectively solidly welded with the suspension wire column 6 and the adjustable suspension wire column 9, and the insulating tube 8 is a glass tube or The ceramic tube, specifically, the upper end surface of the torque coil 4 is provided with a connecting plate 12, and the connecting plate 12 is connected to the torque coil 4 and one end of the suspension wire 5 at the same time. Described suspension wire column 6 and adjustable suspension wire column 9 are all g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com