Triangular mechanism for computer flat knitting machine plain flat knitter

A technology of flat knitting machines and guide needle cams, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of strict machining accuracy of needle jacks 17, complex structure of knitting needle components, and increased manufacturing costs, and achieve The head drive is light and flexible, the movement resistance is reduced, and the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

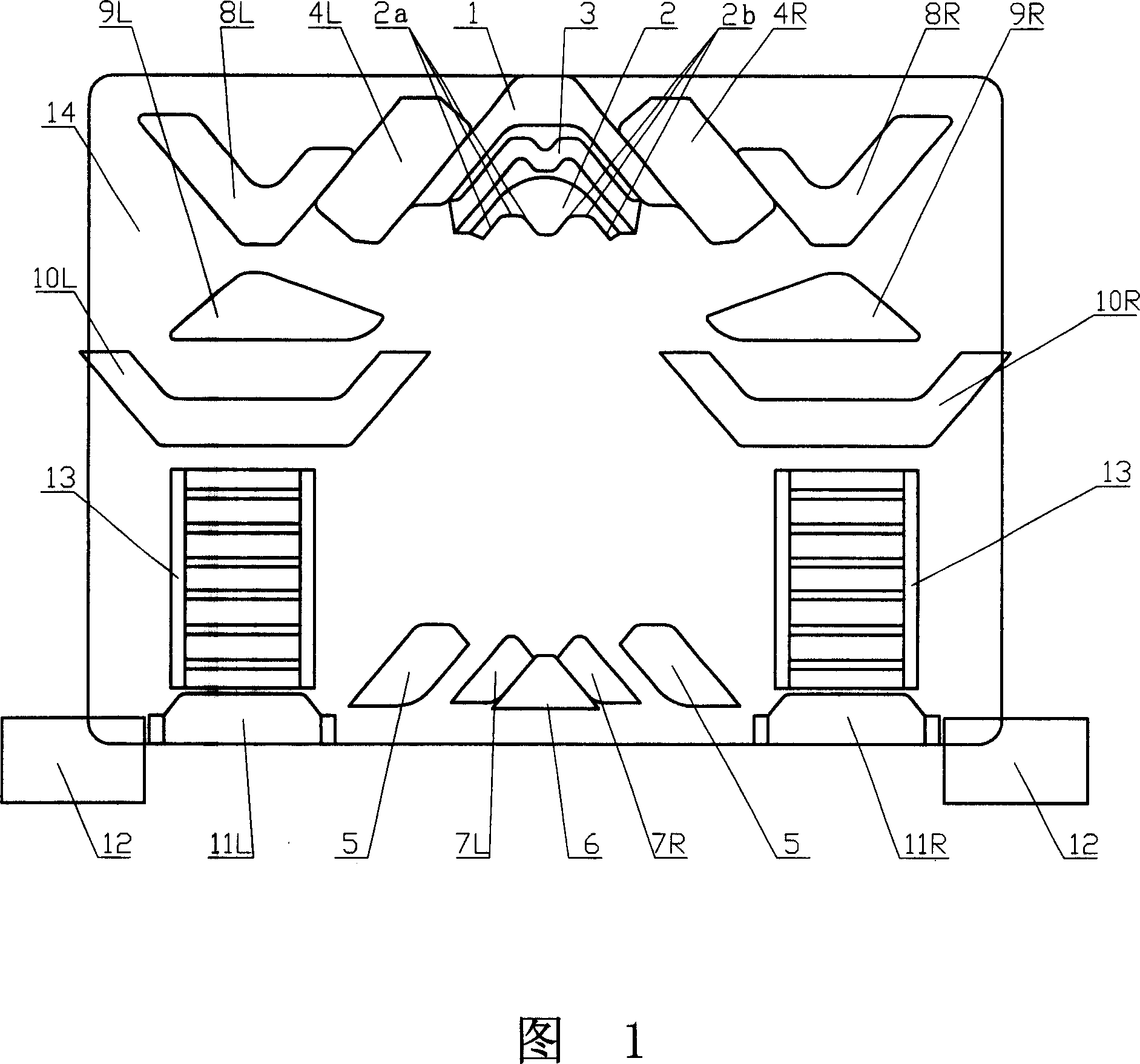

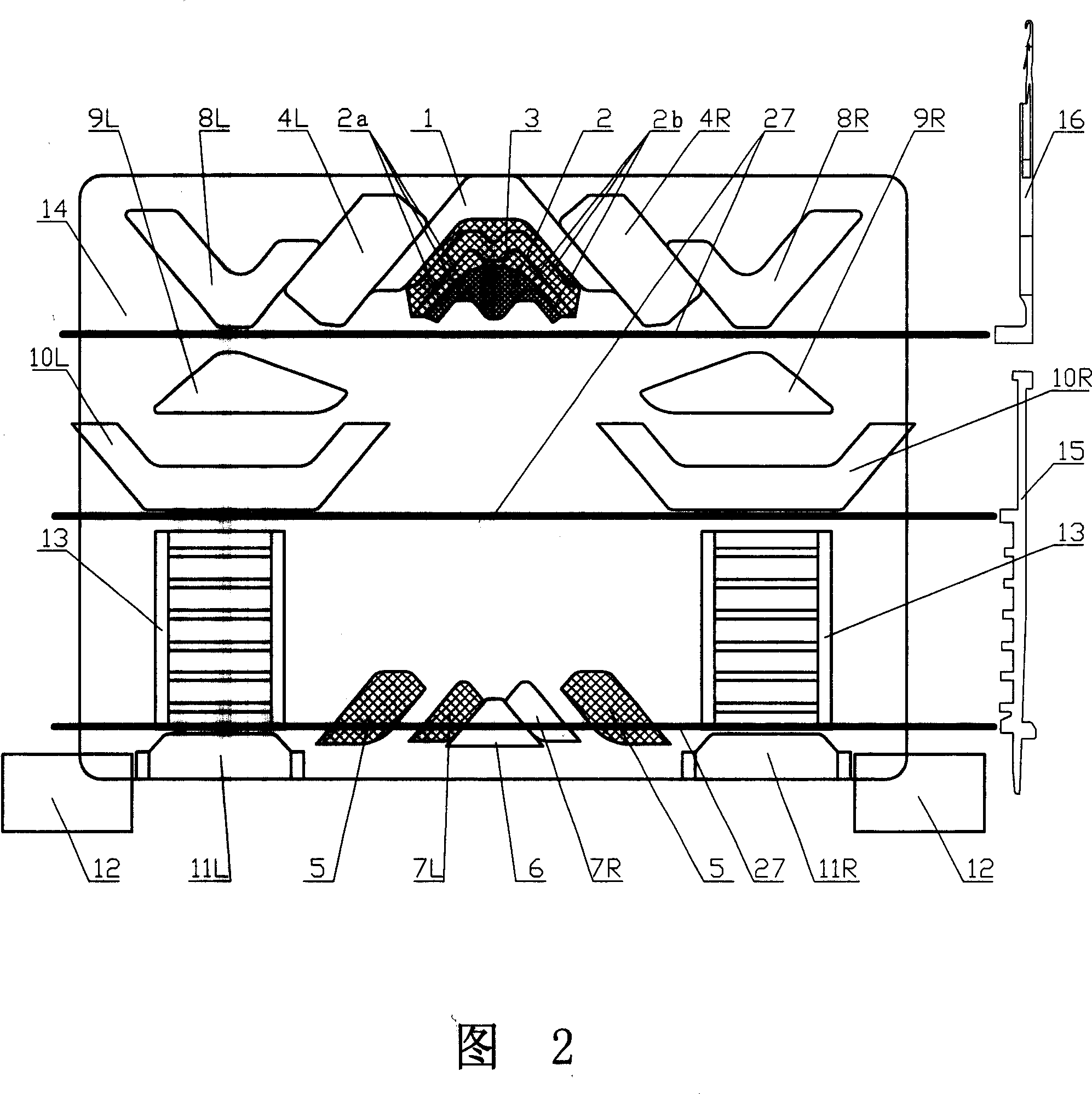

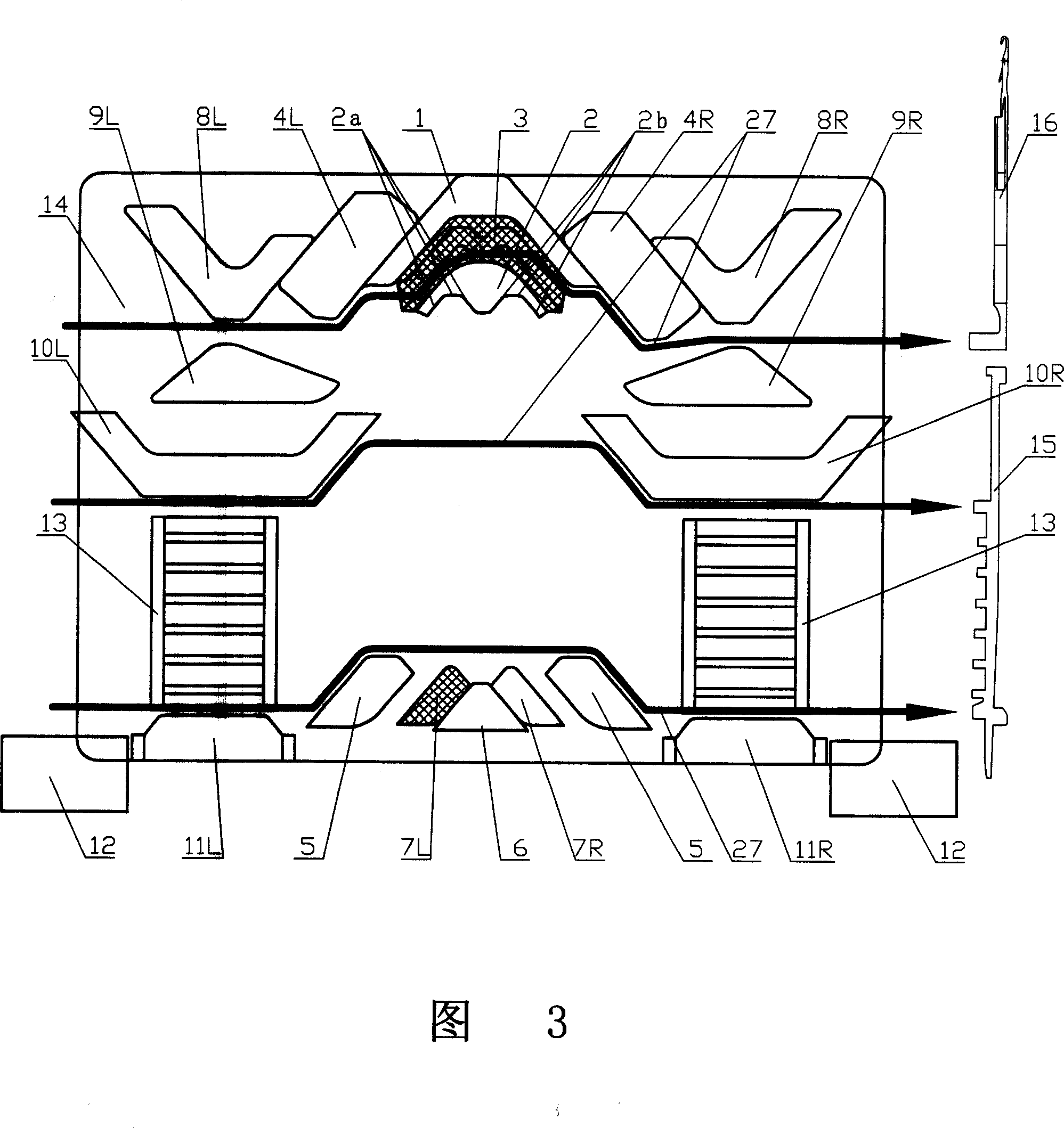

[0032]See also Fig. 1, have provided a rectangle and have triangular bottom plate 14, and it is installed on the machine head of computer knitting flat knitting machine, and it has a pair of front and rear sides that are respectively installed in machine head, thereby on the left side of machine head , Right reciprocating row moves down and drives the knitting needle work of the knitting needle assembly that is positioned at needle plate or claims the needle bed. Taking the position shown in the figure as an example, a pair of generally V-shaped guide pin cams 8L and 8R are respectively fixed with screws on two sides of the upper part of the triangular bottom plate 14, and L and R appearing here represent left and right respectively. (The same below). A pair of guide pin cams 9L, 9R are respectively fixed with screws below the corresponding guide pin cams 8L, 8R, and a pair of guide pin cams are respectively fixed with screws at the lateral near-middle part of the triangular b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com