Fiber reinforced composite material for dental root canal post and preparation method thereof

A composite material and fiber reinforced technology, applied in the direction of dental preparation, fiber type, fiber treatment, etc., can solve the problems of elastic modulus mismatch, difficult matrix bonding, easy corrosion and sensitization, etc., to improve repair life and improve deflection. performance, avoiding the effect of delamination between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Preparation of thermosetting fiber resin composite material:

[0029] Raw materials: bisphenol A epoxy resin (E-51, epoxy value 0.48~0.54eq / 1009); methyltetrahydrophthalic anhydride (MeTHPA, analytically pure); 2,4,6-tris(dimethylaminomethyl ) phenol (DMP-30, chemically pure); PBO fiber (Zylon AS, Toyobo, Japan); silane coupling agent (Z-6040, Dow Corning, USA); acetone (analytical grade); deionized water; TiO 2 (particle size 25nm, Sigma Company, USA); titanate coupling agent (Sigma Company, USA); ether diluent; tetra-n-butyl titanate; triethanolamine; absolute ethanol.

[0030] (1) Resin-based nano-toughening

[0031] A. Nano-TiO 2 Pretreatment: take nano TiO 2 0.5% to 1.0% titanate coupling agent of the mass of the pellets, use 2 to 5 times the ether diluent, adjust the pH value to 7 to 9, fully disperse for 30 minutes with a high-speed emulsifying shearer, add the pellets and stir well , and then raise the temperature to 100-120°C, disperse for an...

Embodiment 2

[0044] Embodiment 2: Preparation of photocurable fiber resin composite material:

[0045] Raw materials: bisphenol A glycidyl methacrylate (Bis-GMA, chemically pure, Aldrich Company); triethylene glycol dimethacrylate (TEGDMA, chemically pure, Aldrich Company); catalyst camphorol (CQ, chemically pure Pure, Aldrich Company); initiator N,N-dimethylaminoethyl methacrylate (DMAEMA, Aldrich Company); PBO fiber (Zylon AS, Toyobo Company, Japan); silane coupling agent (Z-6040, Dow Corning, USA); acetone (analytical grade); deionized water; nano-TiO 2 (particle size 25nm, Sigma Company, USA); titanate coupling agent (Sigma Company, USA); ether diluent; tetra-n-butyl titanate; triethanolamine; absolute ethanol; self-made glass tube mold (specification: Length 100±1mm, diameter 2±0.02mm).

[0046] (1) Resin-based nano-toughening

[0047] A. Nano-TiO 2 Pretreatment: take nano TiO 2 0.5% to 1.0% titanate coupling agent of the mass of the pellets, use 2 to 5 times the ether diluent, a...

Embodiment 3

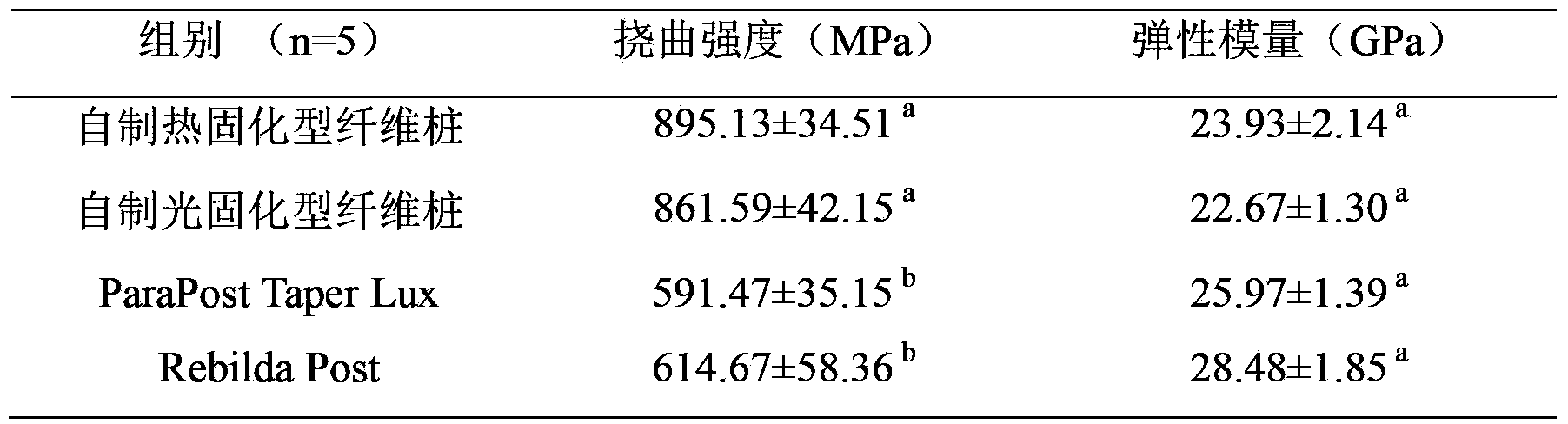

[0056] Example 3: Flexural performance test of four different fiber piles:

[0057] Materials: ParaPost Taper Lux (Conte, Switzerland), Rebilda Post (VOCO, Germany), self-made PBO light-cured fiber post and self-made PBO heat-cured fiber post, the selected model is Ф1.5mm.

[0058] (1) For each group of 10 samples, use an electronic digital caliper to measure the diameter at the midpoint of the length of each group of samples, and calculate the average value of the diameter of each group of fiber piles.

[0059] (2) According to the IS04597-2 standard, conduct a three-point bending strength test to test its flexural strength (MPa) and elastic modulus (GPa). Keep the indoor temperature (22±1)℃, humidity (50±10)%, the span between fulcrums is 10mm, the loading position is the diameter test point, the loading direction is perpendicular to the long axis of the fiber pile, the loading speed is 1.0mm / min, and the uniform acceleration Press until the sample is broken. Record the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com