Engaging double-screw rod spinning pearl functional fibre and manufacturing process thereof

A functional fiber and manufacturing process technology, applied in the chemical field, can solve the problems of affecting spinning forming and fiber tensile properties, affecting the effective function of pearl functional fiber, reducing the effective content of pearl powder, etc., so as to avoid migration and re-agglomeration, The effect of avoiding hole plugging and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

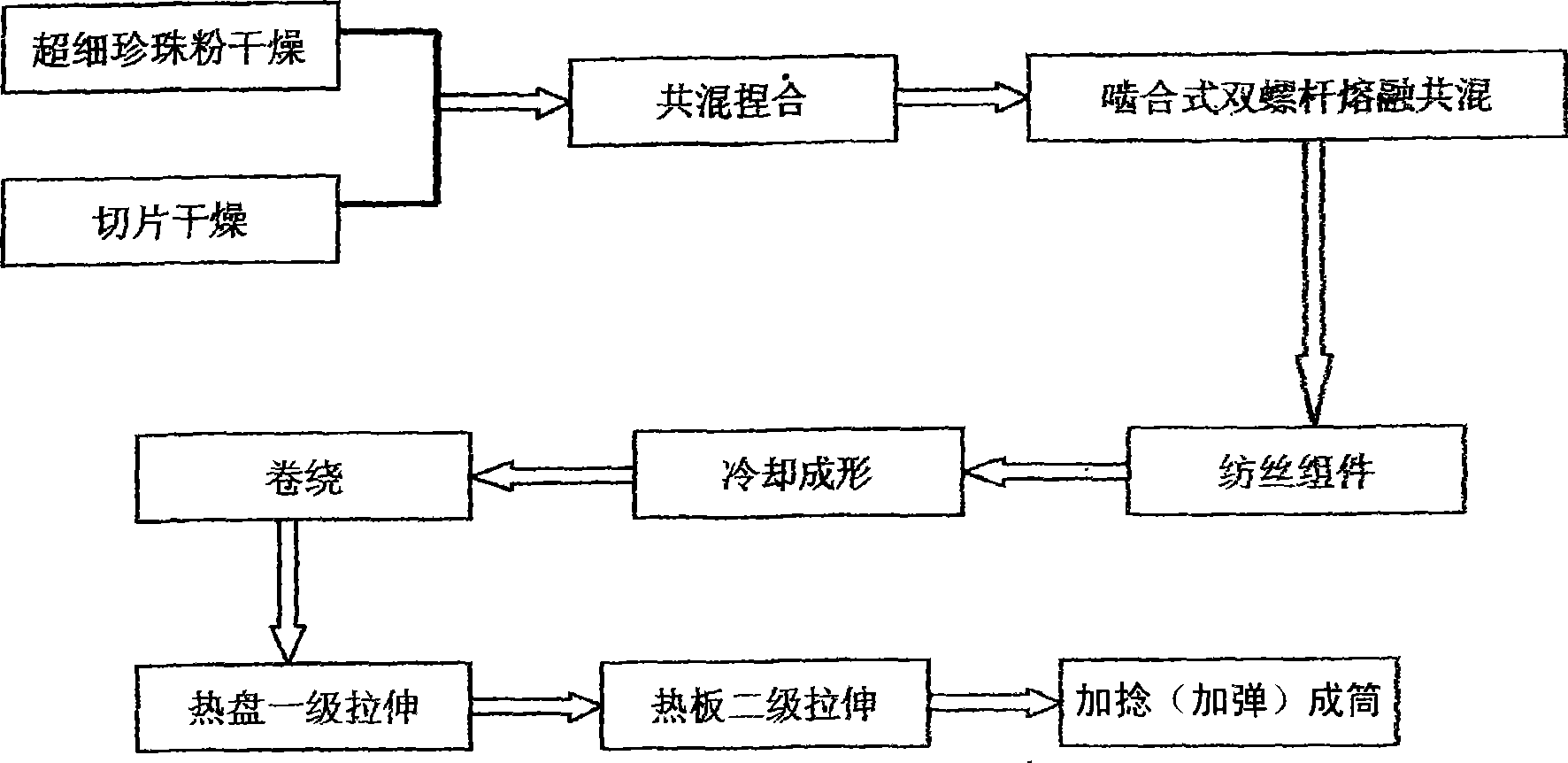

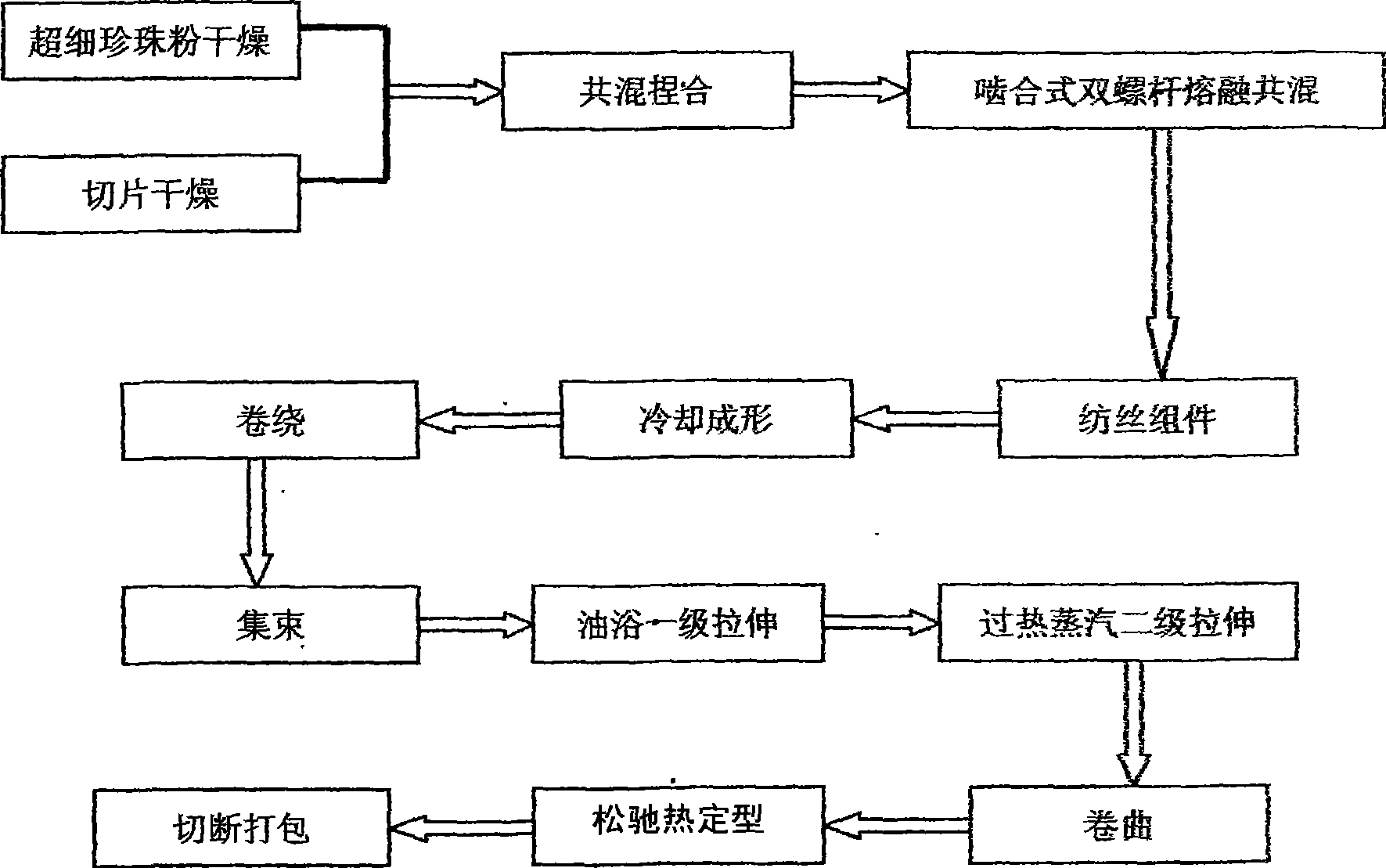

Method used

Image

Examples

Embodiment 1

[0035] Raw materials: pearl powder, the average particle diameter is less than 1μm; melt-spun chips: PET.

[0036] Drying process: polyester chips, vacuum drum drying, heating from 70°C to 130°C for 7 hours, holding at 130°C for 6 hours, cooling for 1 hour and then discharging. Pearl powder, dry at 115°C for 5 hours.

[0037] Stirrer form, anchor wheel type rotation. 1 ton of dried polyester slices, 15Kg of pearl powder, 1.5Kg of ethylene bisstearic acid amide and 1.5Kg of antioxidant 1010 were added, stirred and mixed for 15 minutes, and put into a storage barrel. Enter the screw feed tube.

[0038] The temperature of each zone of intermeshing twin-screw is as follows:

[0039]

cool down

Area Feed

Area warm up

Area to melt

Area kneading

Area measurement

Area flange

bent pipe

cabinet

temperature

/ °C 50 200 245 270 275 270 265 270 272

[0040] Engaging twin-screw pressure 70kg / cm ...

Embodiment 2

[0043] Raw materials: pearl powder, the average particle diameter is less than 1μm; melt-spun chips: PA6.

[0044]Drying process: PA6 slices, stripped for 4 hours, vacuum dried, heated from 80°C to 125°C for 7 hours, kept at 125°C for 6 hours, cooled for 1 hour and then discharged. Pearl powder, dry at 115°C for 5 hours.

[0045] Stirrer form, anchor wheel type rotation. 1 ton of PA6 dried slices, 20kg of pearl powder, 1.6Kg of ethylene bisstearamide and 1.6Kg of antioxidant 1010 were added, stirred and mixed for 15 minutes, and put into the storage barrel. Enter the screw feed tube.

[0046] The temperature of each zone of intermeshing twin-screw is as follows:

[0047]

cool down

Area Feed

Area warm up

Area to melt

Area kneading

Area measurement

Area flange

bent pipe

cabinet

temperature

/ °C 40 190 240 265 270 270 260 265 268

[0048] Engaging twin-screw pressure 65kg / cm 2 , com...

Embodiment 3

[0051] Raw materials: pearl powder, the average particle diameter is less than 1μm, melt-spun chips: PP

[0052] Drying process: pearl powder, 115 ℃ hot air drying for 5 hours.

[0053] Stirrer form, anchor wheel type rotation. 1 ton of PP dried chips, 25kg of pearl powder,

[0054] Add stearic acid amide 0.08% and antioxidant 10100.08%, stir and mix for 15 minutes, and enter the storage barrel. Enter the screw feed tube.

[0055] The temperature of each zone of intermeshing twin-screw is as follows:

[0056]

cool down

Area Feed

Area warm up

Area to melt

Area kneading

Area measurement

Area flange

bent pipe

cabinet

temperature

/ °C 35 165 205 250 255 250 250 255 260

[0057] Meshing twin-screw pressure 72kg / cm 2 , component pressure 150kg / cm 2 , wind speed 0.5m / s, wind temperature 19°C, winding speed 650m / min, total stretching ratio 5.4 times, total denier of bundle 400,000 dtex,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com