Continuous bulk fiber post-processing device

A post-processing device and technology for dispersing fibers, applied in the field of textile dyeing and finishing, can solve the problems of high production cost, large consumption of water and electricity, and large floor space, and achieve lower production costs, smaller floor space, and cleaning effects. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below by means of the accompanying drawings and examples.

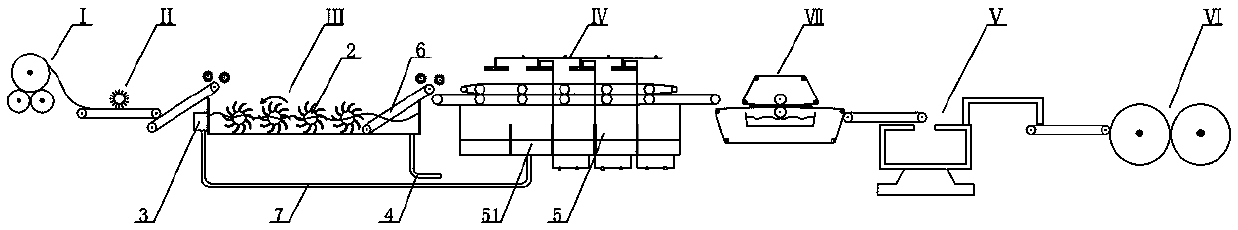

[0020] like figure 1 Shown: a continuous bulk fiber post-processing device, including unwinder Ⅰ, opener Ⅱ, immersion cleaning tank Ⅲ, rolling washing machine Ⅳ, rolling machine Ⅶ, dehydrator Ⅴ and drying machine arranged in sequence Dryer VI.

[0021] The shower rolling washing machine IV has applied for a patent, the patent number is: 201420012281.8, and it mainly realizes the purpose of water washing through the repeated shower rolling process. The shower rolling washing machine IV includes a sump 5, and the sump 5 is divided into several mutually independent tank areas.

[0022] The main technical point of the present invention lies in the immersion type cleaning tank III, and the structure of the immersion type cleaning tank III is described in detail below:

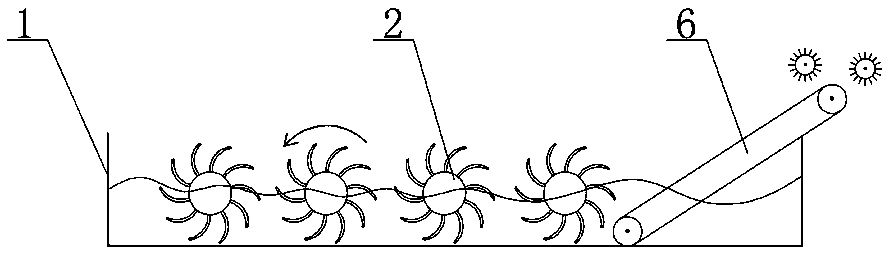

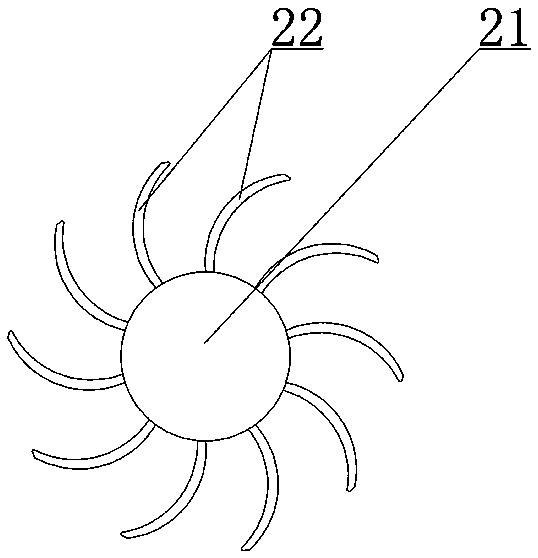

[0023] like figure 2 and image 3 As shown: the immersion cleaning tank III includes a cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com