Preparation method of tough SiO2 aerogel fibers post-processed through isocyanate

An isocyanate and aerogel technology, applied in chemical post-processing of rayon, chemical characteristics of fibers, textiles and papermaking, etc., to achieve the effects of easy availability of raw materials, cheap raw materials and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

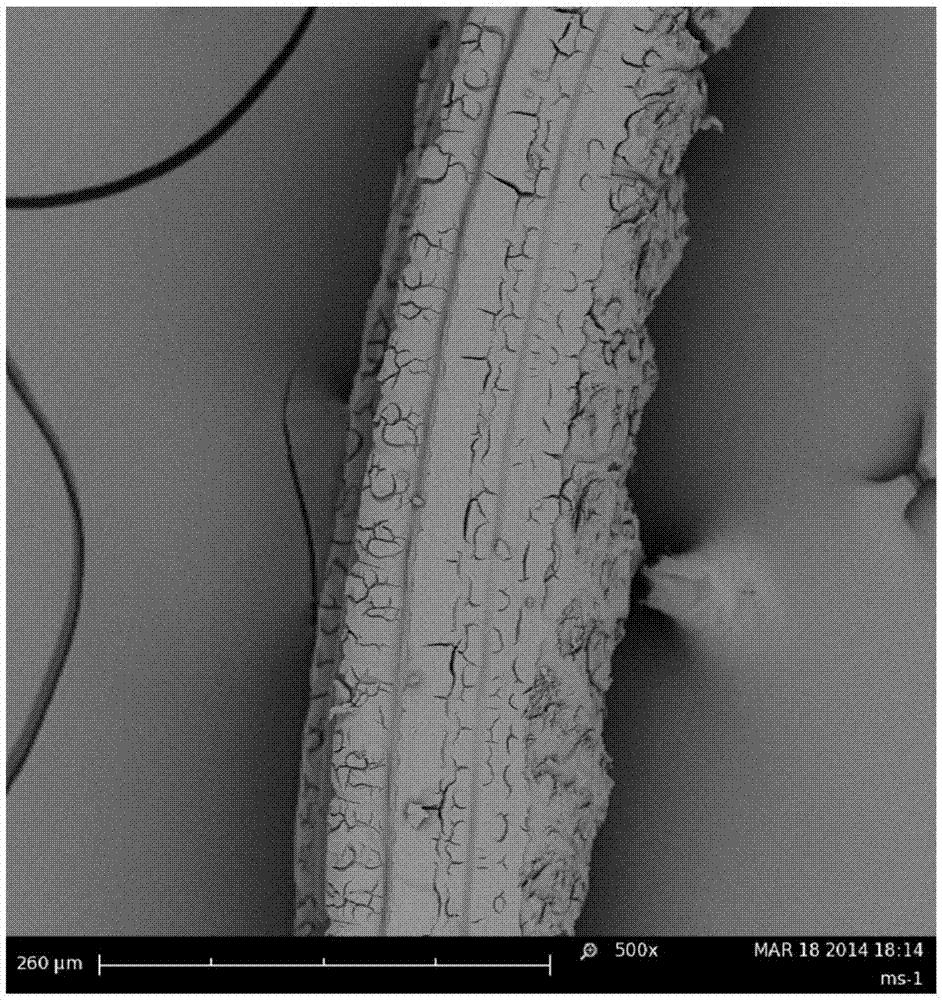

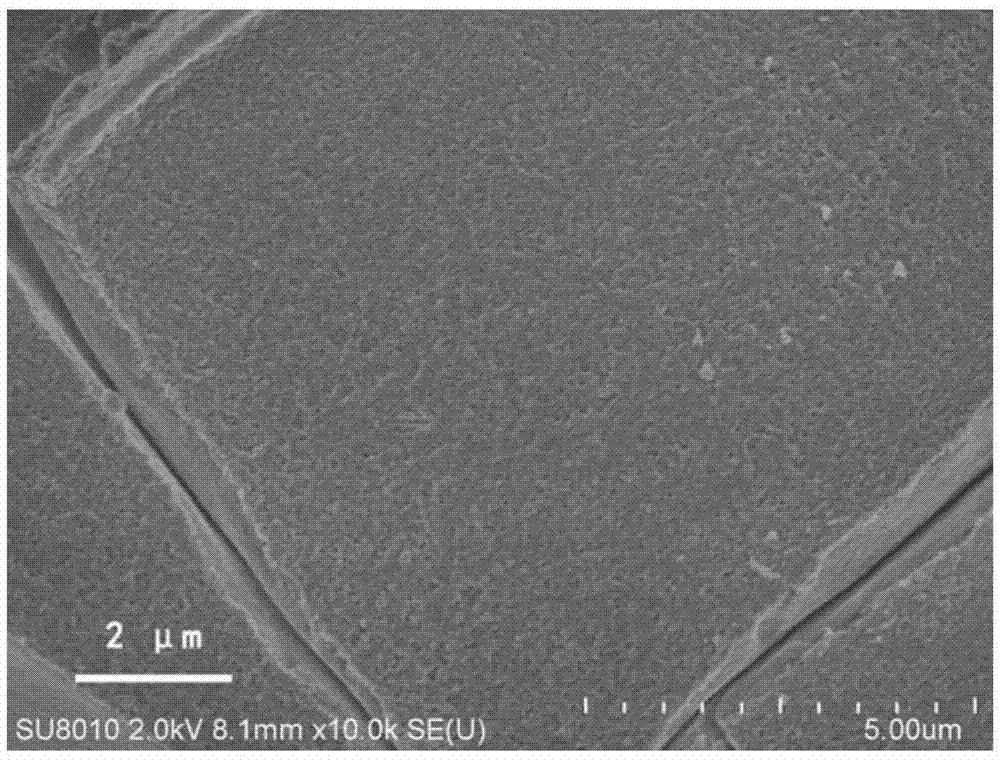

[0032] Sodium water glass with a modulus of 2 and 50 Baume degrees was used as the spinning stock solution, and 0.8 mol / L dilute sulfuric acid solution was used as the coagulation bath to carry out reactive wet spinning. The orthosilicic acid / silicate fiber formed in the coagulation bath was wound at a winding speed of 0.1 m / s. The wound fiber was immersed in 0.005mol / L dilute sulfuric acid for 10 days for aging, so as to realize the transformation from orthosilicic acid / silicate fiber to SiO 2 The fibers are transformed, and a large number of holes are formed at the same time. After aging, wash 3 times with acetone. After washing, place the fiber in a tetrahydrofuran solution of toluene diisocyanate for 48 hours. Toluene diisocyanate and SiO 2 The hydroxyl group on the skeleton reacts. After the reaction is completed, wash with acetone, replace the solution in the fiber with deionized water, and freeze-dry to obtain tough SiO 2 Airgel fibers. The spinning process is very s...

Embodiment 2

[0034] Potassium water glass with a modulus of 3 and 35 degrees Baume was used as the spinning stock solution, and 0.2mol / L dilute sulfuric acid solution was used as the coagulation bath to carry out reactive wet spinning. The orthosilicic acid / sodium silicate fiber formed in the coagulation bath was wound at a winding speed of 0.5 m / s. The wound fiber was immersed in 0.005mol / L dilute sulfuric acid for 10 days for aging, so as to realize the transformation from orthosilicic acid / silicate fiber to SiO 2 The fibers are transformed, and a large number of holes are formed at the same time. After aging, wash 5 times with acetone. After washing, place the fiber in a tetrahydrofuran solution of toluene diisocyanate for 48 hours. Toluene diisocyanate and SiO 2 The hydroxyl group on the skeleton reacts. After the reaction is completed, wash with acetone, replace the solution in the fiber with deionized water, and freeze-dry to obtain SiO 2 Airgel fibers. Occasionally, there is a ph...

Embodiment 3

[0036] Potassium water glass with a modulus of 3 and 35 degrees Baume was used as the spinning stock solution, and 0.8 mol / L dilute sulfuric acid solution was used as the coagulation bath to carry out reactive wet spinning. The orthosilicic acid / potassium silicate fiber formed in the coagulation bath was wound at a winding speed of 1 m / s. The wound fiber was immersed in 0.1mol / L dilute sulfuric acid for 5 days for aging, and the transformation from orthosilicic acid / silicate fiber to SiO 2 The fibers are transformed, and a large number of holes are formed at the same time. After aging, wash 3 times with acetone. After washing, place the fiber in a tetrahydrofuran solution of toluene diisocyanate for 48 hours. Toluene diisocyanate and SiO 2 The hydroxyl group on the skeleton reacts. After the reaction is completed, wash with acetone, replace the solution in the fiber with deionized water, and freeze-dry to obtain SiO 2 Airgel fibers. Occasionally, there is a phenomenon of br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com