Polyester polyol and polyurethane resin for superfine fiber synthetic leather

A technology of polyester polyol and polyurethane resin, which is applied in fiber treatment, textiles and papermaking, etc. It can solve the problems of poor color fastness, weak binding force, late development of polyurethane resin, etc., and achieve less dyeing and fading, good hand feeling, good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

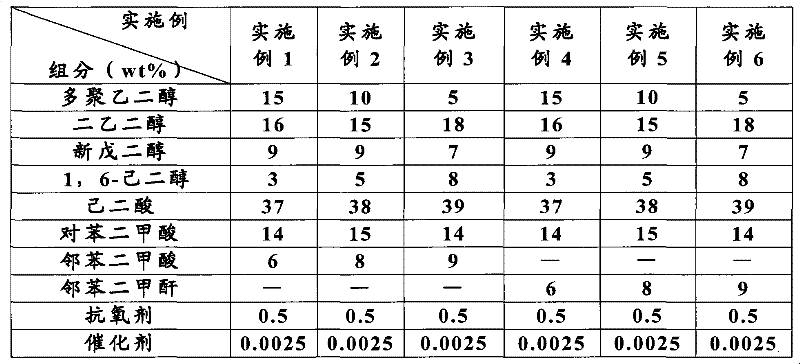

[0016] The polyester polyols according to Examples 1 to 6 adopt the raw material formula listed in Table 1, and are obtained by the following preparation method:

[0017] (1). Pour nitrogen into the reactor, replace the air and add the formula amount of polyethylene glycol, diethylene glycol, neopentyl glycol, 1,6-hexanediol, adipic acid, and p-benzene Dicarboxylic acid, phthalic acid and the antioxidant BHT whose mass is 0.4wt%~0.6wt% of the total weight of the raw materials, start dehydration when the temperature is raised to 150~160℃, and continue to heat up to 200℃ after constant temperature dehydration for about 4 hours constant temperature.

[0018] (2) Continuously carry out acid value test during the constant temperature process, when the acid value is reduced to 5, add a catalyst with a mass of 20-30PPM of the total weight of the raw materials, and continue the reaction until the acid value is less than 1, and the hydroxyl value is 53-59. , And then continue to keep heat ...

Embodiment 7~12

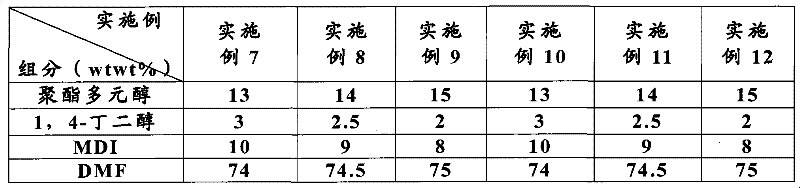

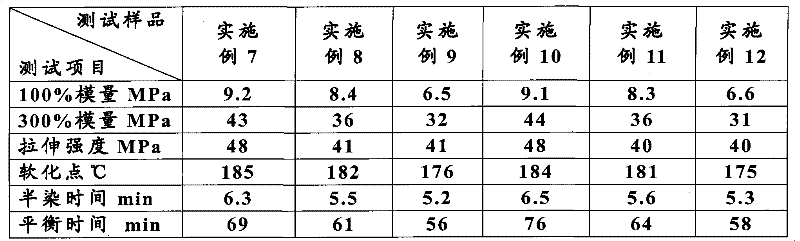

[0022] Examples 7 to 12 provide polyurethane resins for ultrafine fiber synthetic leather. They use the polyester polyols of Examples 1 to 6, according to the raw material formula in Table 2, and are prepared by the following method: Fill the reactor Nitrogen, add DMF, polyester polyol, 1,4-butanediol and MDI in order, react at 75℃, when it reaches the specified polymerization viscosity Z 3 ~Z 4 After cooling down, polyurethane resin is obtained.

[0023] Table 2 The raw material formula of the polyurethane resin of Examples 7-12

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com