Desulfurizing tower

A desulfurization tower and desulfurization zone technology, applied in the field of desulfurization towers, can solve the problems of short interaction time, unfavorable efficient and economical operation, land occupation, large investment, etc., and achieve long residence time, reduce slurry circulation, and save investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

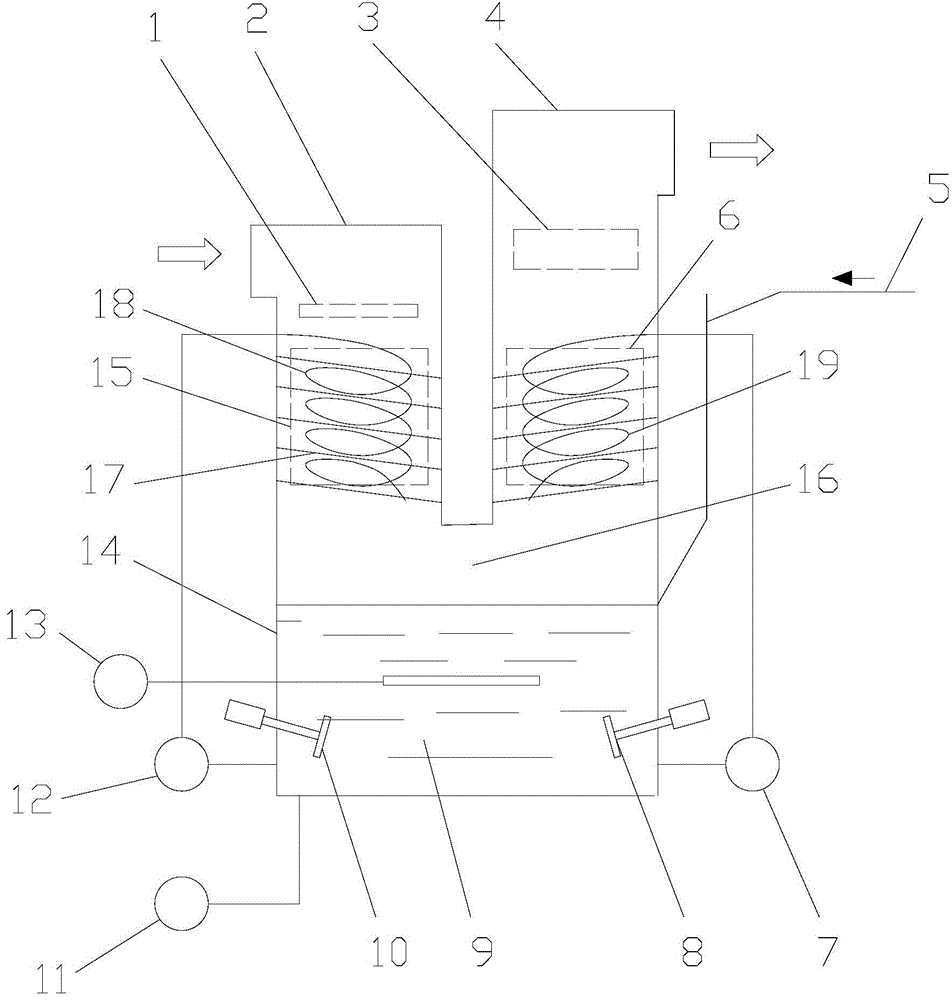

[0018] figure 1 It is a structural schematic diagram of the present invention. As shown in the figure, the desulfurization tower of the present invention includes a desulfurization tower body, and the upper part of the desulfurization tower body 14 is a downstream tower 2 and a countercurrent tower 4 separated from each other. There is a flue gas inlet, and the countercurrent tower 4 is provided with a flue gas outlet. The lower part of the desulfurization tower body 14 is a slurry pool 9; The forward circulation desulfurization zone 15 is arranged in the forward flow tower 2, and the rear circulation desulfurization zone 6 is arranged in the countercurrent tower 4. Vertical spiral guide vanes 17 are provided, the front circulation desulfurization zone 15 is connected to the slurry pool 9 through the front circulation pump 12, and the rear circulation desulfurization zone 6 is connected to the slurry pool 9 through the rear circulation pump 7; the outlet of the front circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com