Liquefied gas desulfurizing and refining method

A technology for liquefied gas and oxidative sweetening of mercaptans, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of excessive total sulfur content of liquefied gas, high catalyst cost, easy aggregation and deactivation, etc., and achieve good industrial application prospects, desulfurization The agent is simple and easy to obtain, and the effect of desulfurization is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

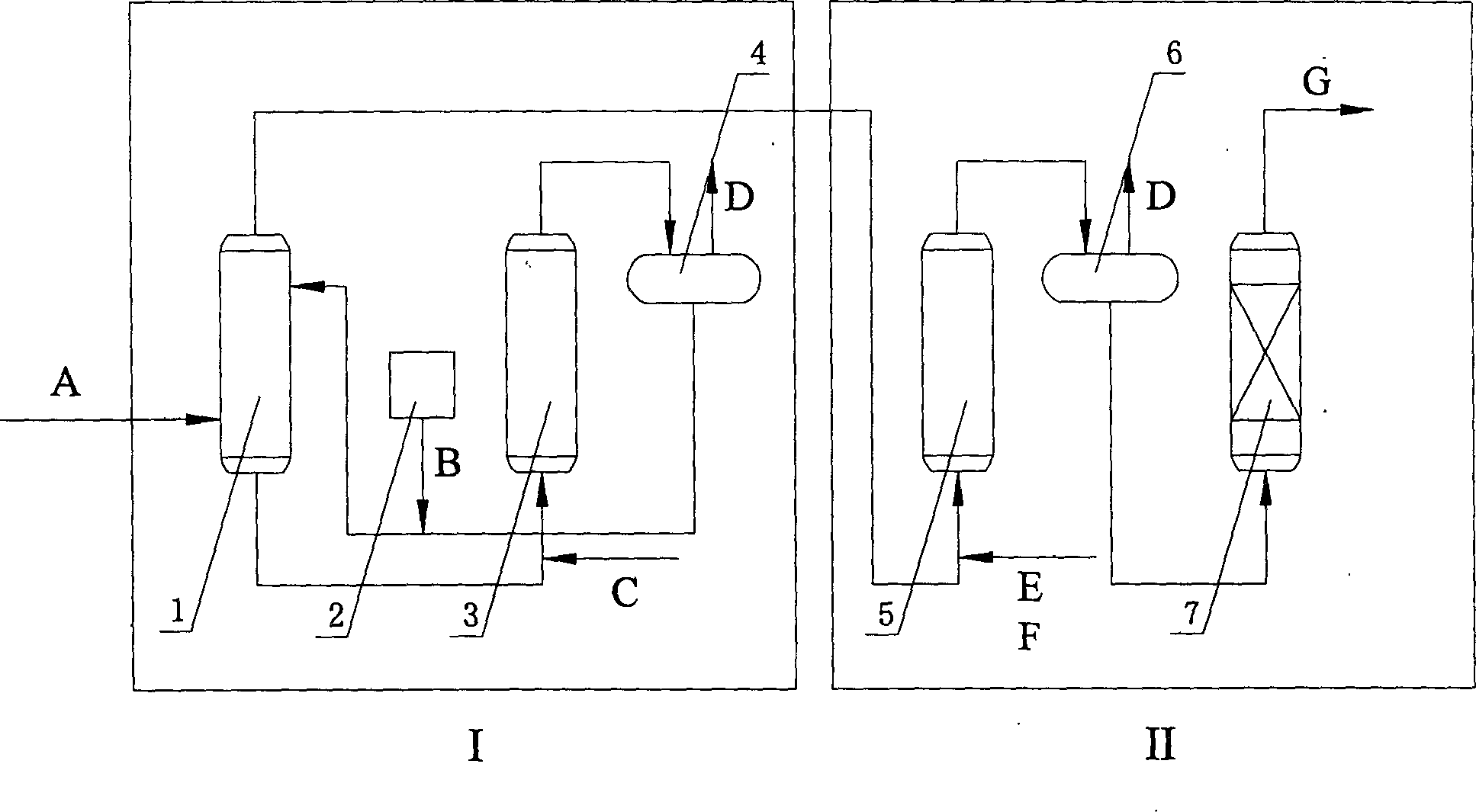

Method used

Image

Examples

Embodiment

[0046] project

[0047] It can be seen from the above data that the desulfurization and refining effect of liquefied petroleum gas by using desulfurizer is very obvious. to H 2 The effect of S coming out is very good, after taking off H 2 The S content is only 20ug / g, and the removal rate is over 95%. At the same time, it also has a certain function of removing mercaptan and total sulfur, and the removal rate of mercaptan and total sulfur is about 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com