Compound cigarette filter tip

A technology for cigarettes and filters, applied in the field of filters, which can solve the problems of single function of the filter element, difficulty in obtaining porous structure, difficulty in satisfying complex situations, etc., and achieve the effects of expanding the scope of use, improving comprehensive performance, and improving filtration accuracy and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

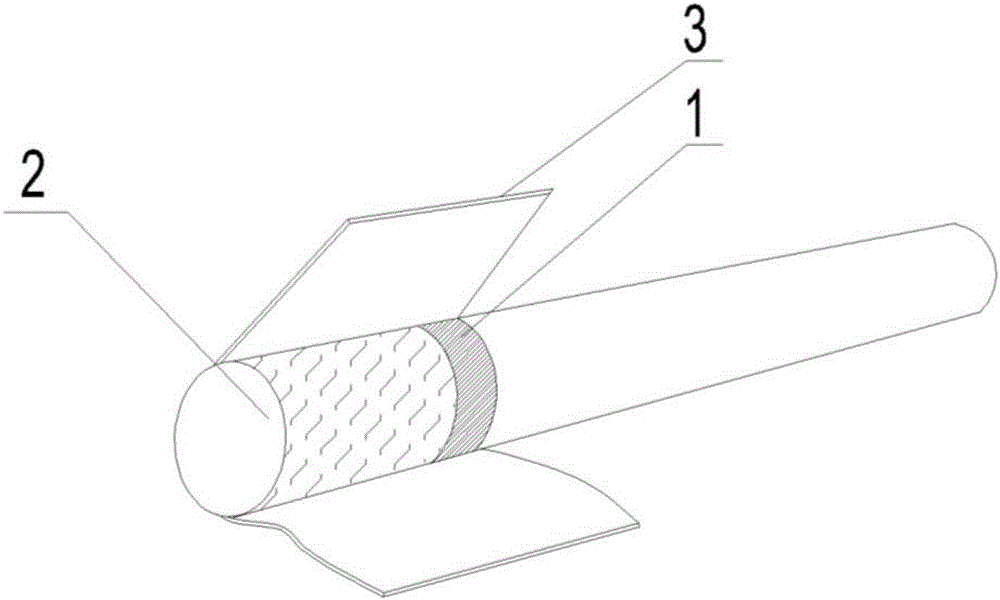

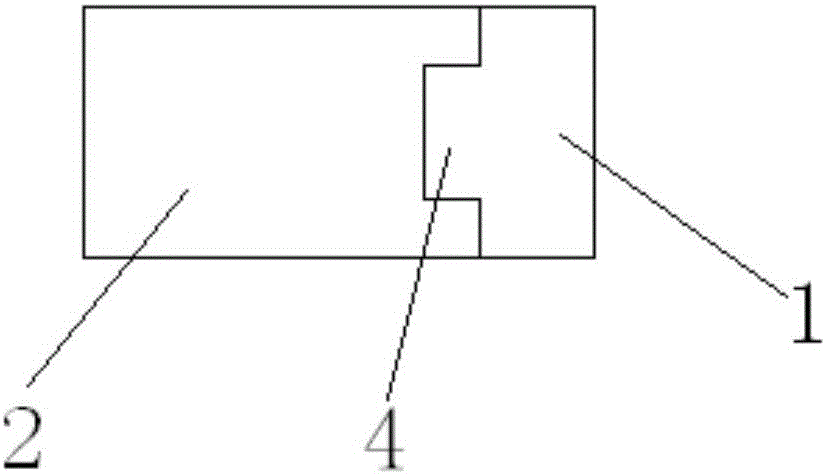

[0056] Such as figure 1 figure 2 As shown, the present invention relates to a composite cigarette filter, comprising a filter tip section near the lip end, a filter tip section near the shredded tobacco end and wrapping paper, the filter tip section near the lip end is connected with the filter tip section near the shredded tobacco end through a fitting structure, and the fitting structure includes The groove at the end of the filter section near the lip end and the columnar protrusion at the front end of the filter section near the shredded tobacco, the cylindrical protrusion matches the shape of the groove, the length ratio of the filter section near the lip end to the filter section near the shredded tobacco end is 3:1, wrapping paper Wrapped on the outside of the filter section near the lip end and the filter section near the shredded tobacco end, the wrapping paper is tipping paper, and there are air holes on the wrapping paper, and the filter tip section near the lip en...

Embodiment 2

[0059] Such as figure 1 figure 2 As shown, the present invention relates to a composite cigarette filter, comprising a filter tip section near the lip end, a filter tip section near the shredded tobacco end and wrapping paper, the filter tip section near the lip end is connected with the filter tip section near the shredded tobacco end through a fitting structure, and the fitting structure includes The groove at the end of the filter section near the lip end and the columnar protrusion at the front end of the filter section near the shredded tobacco, the cylindrical protrusion matches the shape of the groove, the length ratio of the filter section near the lip end to the filter section near the shredded tobacco end is 5:1, wrapping paper Wrapped on the outer side of the filter section near the lip end and the filter section near the shredded tobacco end, the wrapping paper is tipping paper, the filter tip section near the lip end is provided with a fiber filter layer, the fib...

Embodiment 3

[0062] Such as figure 1 As shown, the present invention relates to a composite cigarette filter, comprising a filter tip section near the lip end, a filter tip section near the shredded tobacco end and wrapping paper, the filter tip section near the lip end is connected with the filter tip section near the shredded tobacco end through a fitting structure, and the fitting structure includes The groove at the end of the filter section near the lip end and the columnar protrusion at the front end of the filter section near the shredded tobacco, the cylindrical protrusion matches the shape of the groove, the length ratio of the filter section near the lip end to the filter section near the shredded tobacco end is 10:1, wrapping paper Wrapped on the outside of the filter section near the lip end and the filter section near the shredded tobacco end, the wrapping paper is tipping paper, the filter tip section near the lip end is provided with a fiber filter layer, the fiber filter lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Temperature resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com