Smoke desulfurization device and method

A technology for desulfurization equipment and soot, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of short contact time between soot and desulfurization liquid, poor desulfurization effect, and small contact area, so as to increase the desulfurization reaction. area, avoiding waste of energy, and prolonging the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

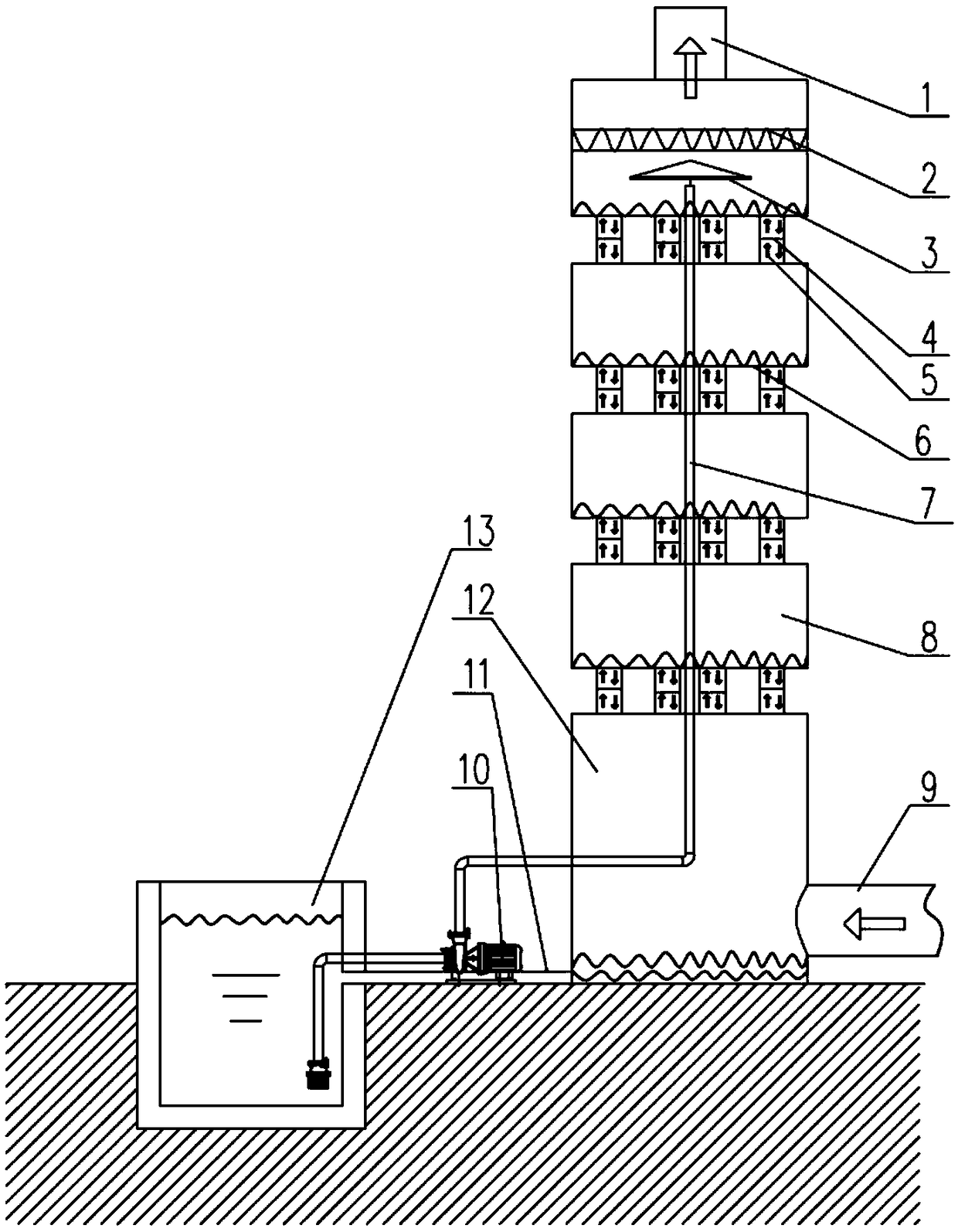

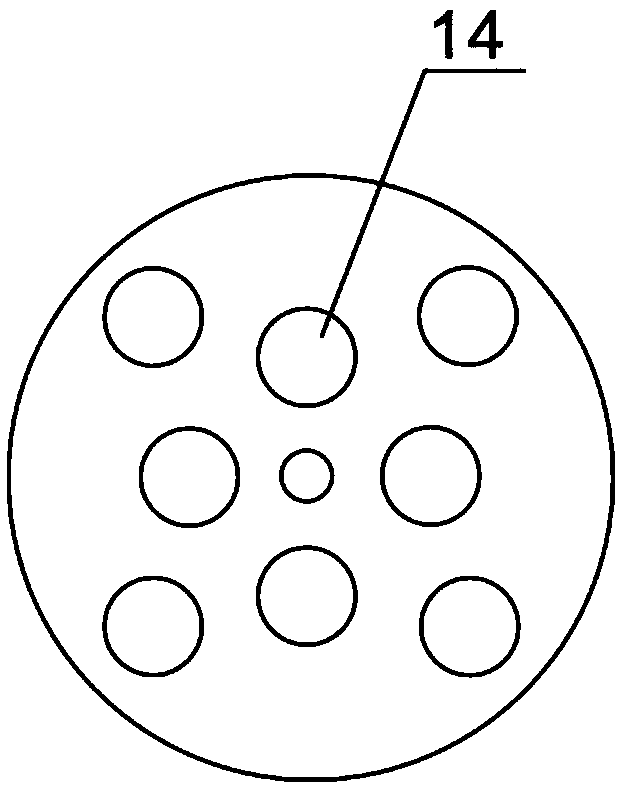

[0030] This embodiment provides a soot desulfurization device, such as Figure 1 to Figure 2 As shown, there are multiple desulfurization cylinders 8 and upper liquid pipes 7, and the number of desulfurization cylinders 8 is multiple. The adjacent desulfurization cylinders 8 are vertically connected through the desulfurization channels 5, and the desulfurization liquid liquid surface is formed on the bottom plate 6 of the desulfurization cylinders 8; The upper liquid pipe 7 is arranged through the center of the desulfurization cylinder 8 , and the liquid outlet of the upper liquid pipe 7 is located in the top desulfurization cylinder 8 .

[0031] During implementation, the water pump 10 is used to feed the desulfurization liquid into the top desulfurization cylinder 8 through the upper liquid pipe, and the desulfurization liquid flows from the top desulfurization cylinder 8 to the bottom desulfurization cylinder 8, forming a plurality of desulfurization liquids on the bottom pl...

Embodiment 2

[0047] This embodiment provides a soot desulfurization method, specifically using the soot desulfurization device in Embodiment 1 for desulfurization, including the following steps:

[0048] Step 1: Turn on the water pump, supply desulfurization liquid into the top desulfurization cylinder, the desulfurization liquid flows from the upper desulfurization cylinder to the lower desulfurization cylinder, and form multiple desulfurization liquid levels on the bottom plate 6 of multiple desulfurization cylinders 8 .

[0049] Before step 1, first fill the desulfurization liquid pool 13 with desulfurization liquid of appropriate concentration, and select appropriate power pumps and fans according to parameters such as the amount of soot to be desulfurized and the sulfur content of the soot, and complete other preparatory work before desulfurization. If the desulfurization cylinder 8 and the desulfurization passage 8 are detachable structures, select an appropriate number of desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com